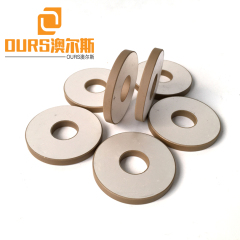

15.6X9.4X5MM Tube Piezoelectric Ceramic Materials PZT-8 For Piezo-ceramic Sensors

50-9999 Piece

$8.50

≥ 10000 Piece

$6.50

- Item No.ARS-YZJP-15.6X9.4X5MMMOQ50 Piece

Choice

Online customization Customise Now

Customized logo (Min. Order: 50 Piece)

Customized packaging (Min. Order: 50 Piece)

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

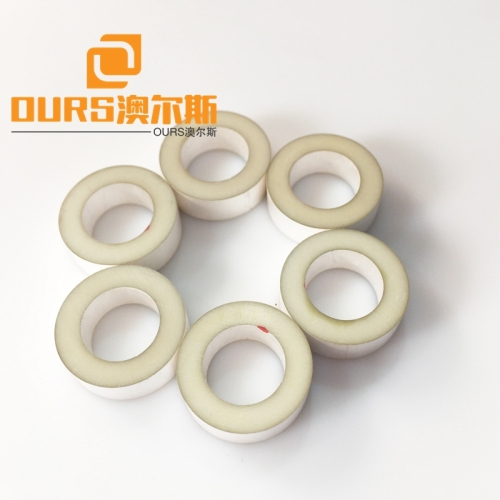

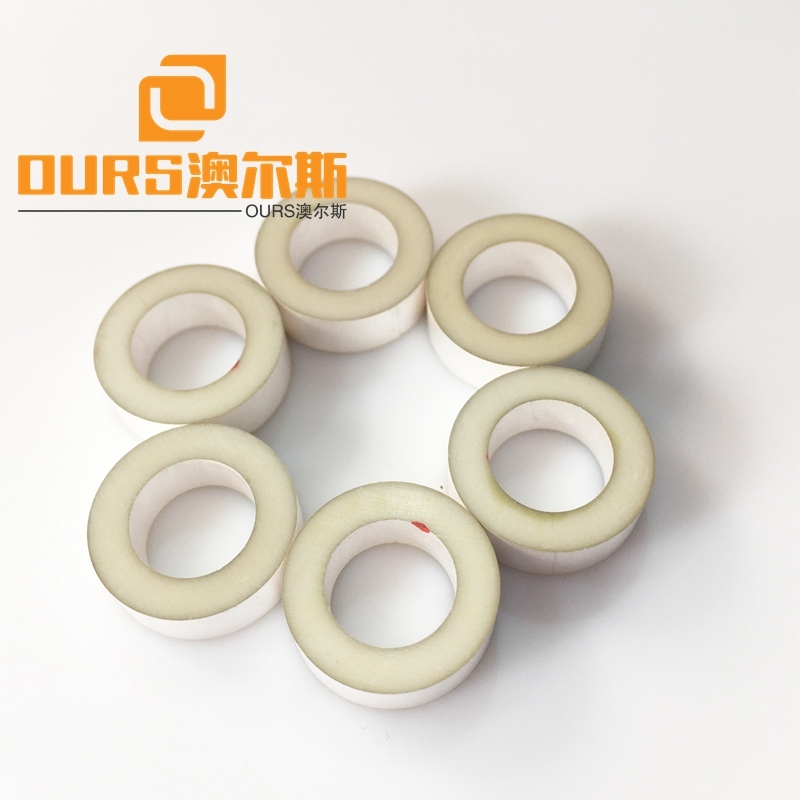

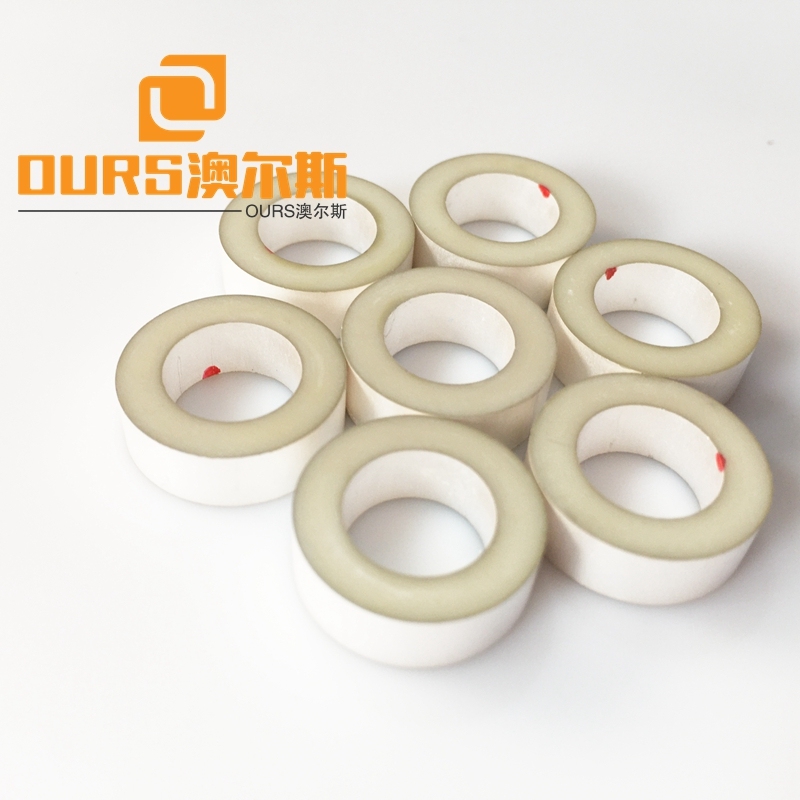

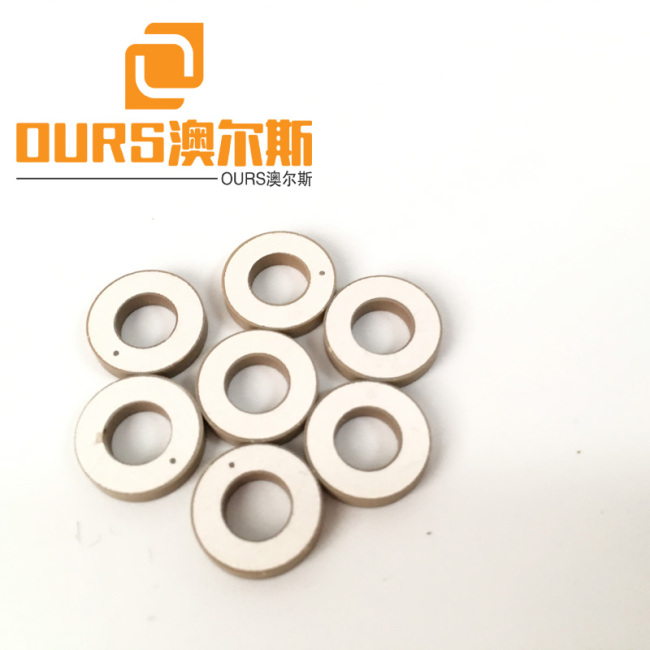

15.6X9.4X5MM Tube Piezoelectric Ceramic Materials PZT-8 For Piezo-ceramic Sensors

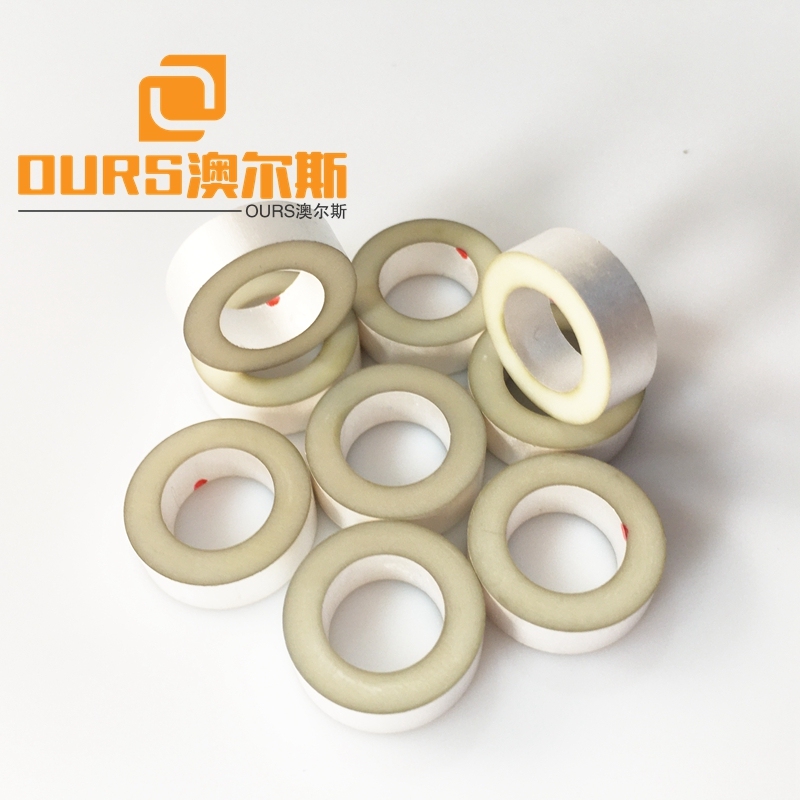

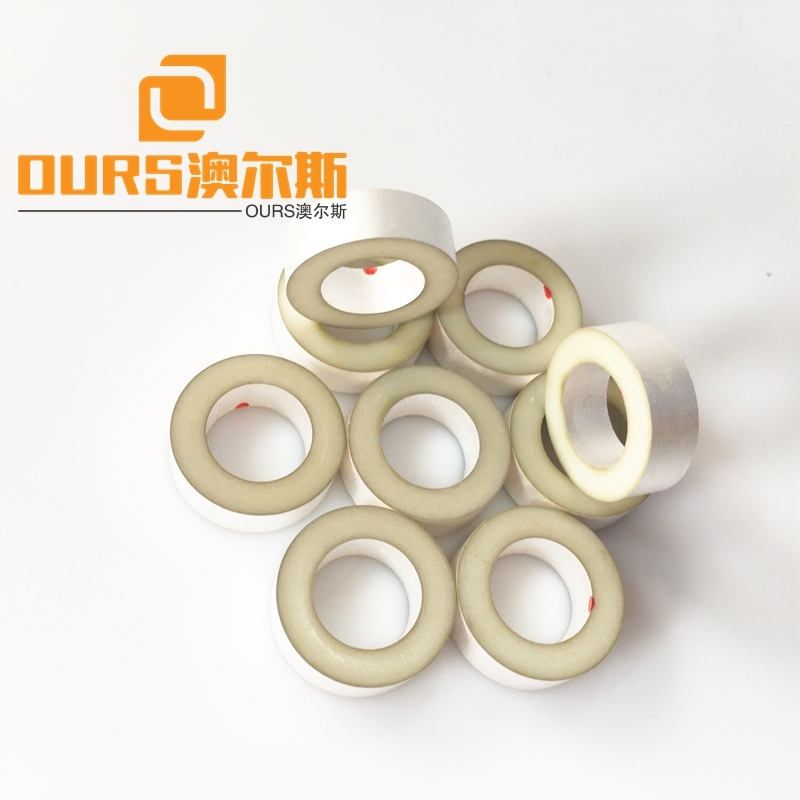

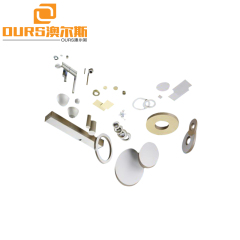

![]() Piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

Piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

Piezoelectric Sensors

A piezoelectric sensor converts a physical parameter, such as acceleration or pressure, into an electrical signal. In some sensors the physical parameter acts directly on the piezoelectric element; in other devices an acoustical signal establishes vibrations in the element and the vibrations are, in turn, converted into an electrical signal. Often, the system provides a visual, audible, or physical response to the input from the piezoelectric sensor -- automobile seatbelts lock in response to a rapid deceleration, for example.

PiezoelectricCeramics (PZT) materials are categorized as functional ceramics. In sensors they make it possible toconvert forces, pressures and accelerations into electrical signals, and in sonic and ultrasonic transducers and actuators they convert electric voltages into vibrations or deformations.PiezoelectricCeramics materials are classified according to their chemical composition on the one hand, and by the specific application conditions on the other.

In terms of energy conversion, using piezoelectric ceramics to convert external forces into electrical energy, piezoelectric igniters, mobile X-ray power supplies, and shell detonating devices can be manufactured. There are flints made of piezoelectric ceramics in electronic lighters, and the number of ignitions can be more than 1 million. Using piezoelectric ceramics to convert electrical energy into ultrasonic vibration, it can be used to find the position and shape of underwater fish, non-destructive testing of metals, ultrasonic cleaning, ultrasonic medical treatment, and various ultrasonic cutters, welding devices and Soldering iron, processing plastic and even metal.

Piezo-ceramic Applications

In automotive engineering sensors keep passengers safe and ensure intelligent engine management. In ultrasonic applications piezo-ceramic components generate great ultrasonic intensities for ultrasonic cleaning and drilling, ultrasonic welding or for stimulating chemical processes. Still other piezo-ceramic components are used as ultrasonic transmitters and receivers in many areas of signal and information processing applications.

Piezo-ceramic actuators function based on the fact that deformations can be generated in the micrometer range. This behavior opens up new application possibilities for electromechanical transducers as actuators for hydraulic and pneumatic valves, positioning systems, micromanipulators and dispensing systems for liquids and gases.

“Piezo-ceramic components enable ultrasonic localization in sonar technology, distance measurement, non-destructive material testing and medical diagnostics.”

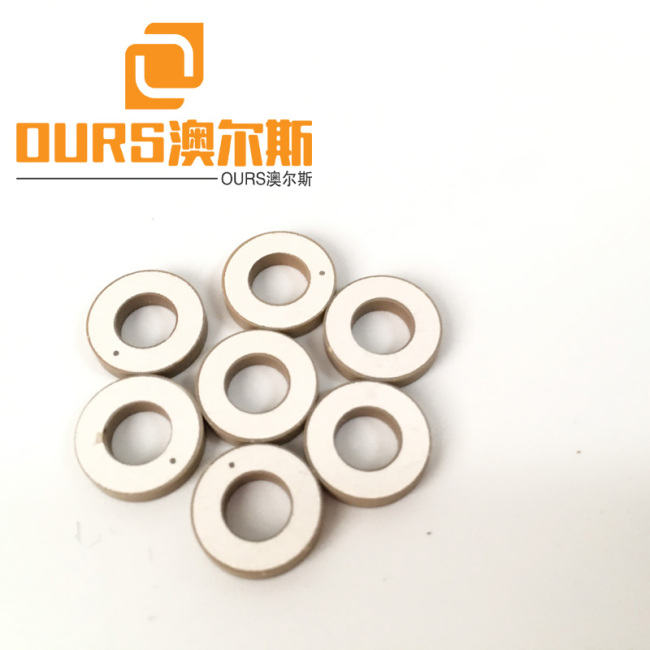

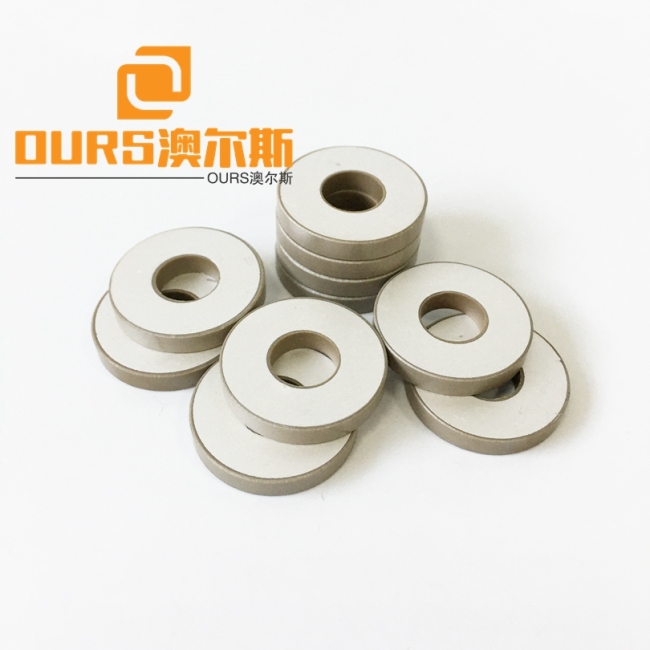

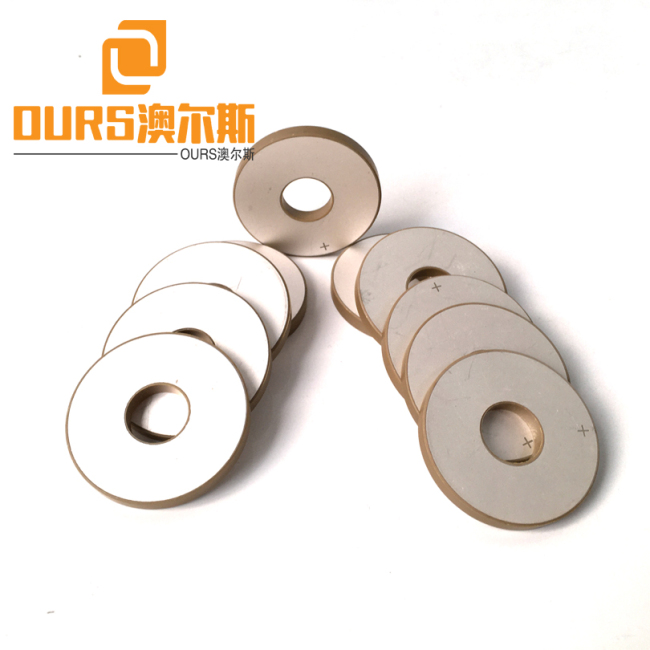

Piezoceramic components, such as plates, disks or rings, convert mechanical signals, such as force, pressure, strain or acceleration, into electrical voltage, or, vice versa, an electrical voltage into mechanical motion or oscillations. The typical resonant frequencies are between 200 kHz and 10 MHz. The shapes and dimensions of the piezo components can be selected within the limits determined by the tools, although the dimensions depend on each other. The minimum dimensions are determined by physical and technological limits. The thickness or wall thickness, for example, is limited by the mechanical strength of the ceramic during machining. In the polarization direction, the dimension is at most 30 mm.

Commonly used piezoelectric ceramics are barium titanate, lead zirconate titanate binary system and the third type of ABO3 added to the binary system (A represents a divalent metal ion, B represents a tetravalent metal ion or the sum of several ions is positive four Valence) type compound, such as: Pb(Mn1/3Nb2/3)O3 and Pb(Co1/3Nb2/3)O3 and other ternary systems. If a fourth or more compounds are added to the ternary system, a quaternary or multi-element piezoelectric ceramic can be formed. In addition, there is a kind of metaniobate piezoelectric ceramics, such as potassium sodium metaniobate (Na0.5•K0.5•NbO3) and barium strontium metaniobate (Bax•Sr1-x•Nb2O5), etc. They are not Toxic lead is good for environmental protection.

Piezoelectric ceramic materials have high electromechanical coupling coefficient, suitable dielectric constant, and high sensitivity. It is mainly used for high-sensitivity transducers, flowmeter transducers, level gauge transducers, accelerometer transducers, ultrasonic detection transducers, etc.

The piezoelectric ceramic sheet material has good piezoelectricity, high mechanical strength, high coercive field, and low dielectric loss in strong fields. It is mainly used for ultrasonic cleaning, powerful ultrasonic drilling, ultrasonic welding, scaler probe, beauty instrument probe, ultrasonic scalpel probe, cardiovascular therapy instrument probe, etc.

Application

1. ultrasonic cleaning trasnducer

2. ultrasonic welding tansducer

3. ultrasonic beauty transducer

4. ultrasonic underwater transducer

5. ultrasonic immersible transucer

6. ultrasonic screening transducer

7. ultrasonic cutting transducer

8. ultrasonic atomization transducer

9. ultrasonic emulsifier

Warmly Welcome Custom made, please email to us or send message for further discussing !

![]()

15.6X9.4X5MM Tube Piezoelectric Ceramic Materials PZT-8 For Piezo-ceramic Sensors

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian