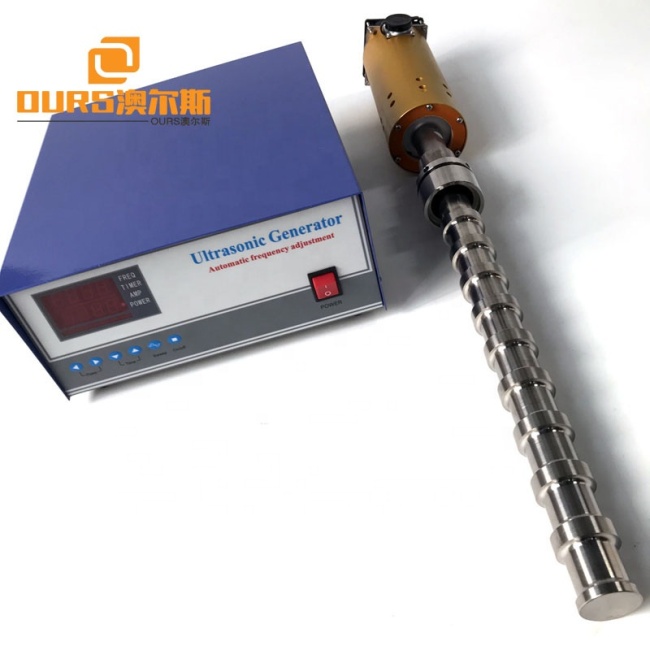

1500W 20KHZ Industrial Design Ultrasonic Material Dispenser Ultrasonic Reactor Supplier

1-4 Set

$2,790.00

≥ 5 Set

$2,600.00

- Item No.20201104cb51fMOQ1 Set

- Product size60 x 55 x 40 mProduct weight45 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

1500W 20KHZ Industrial Design Ultrasonic Material Dispenser Ultrasonic Reactor Supplier

Introduction to the ultrasonic cleaning machine vibrating rod:

Ultrasound refers to electromagnetic waves with a frequency of about 20 kHz to 50 MHz. It is a mechanical wave that requires an energy carrier—a medium—to propagate. There is an alternating period of positive and negative pressure during the transmission of ultrasonic waves. At the positive phase, the molecules of the medium are squeezed to increase the original density of the medium. At the negative phase, the molecules of the medium are sparse and discrete, and the density of the medium is reduced. In other words, ultrasound does not polarize the molecules in the sample, but generates sonic cavitation between the solvent and the sample, leading to the formation, growth, and burst compression of bubbles in the solution, thereby dispersing and increasing the solid sample. The contact area between the sample and the extraction solvent increases the mass transfer rate of the target from the solid phase to the liquid phase. In industrial applications, the use of ultrasound for cleaning, drying, sterilization, atomization and non-destructive testing is a very mature and widely used technology.

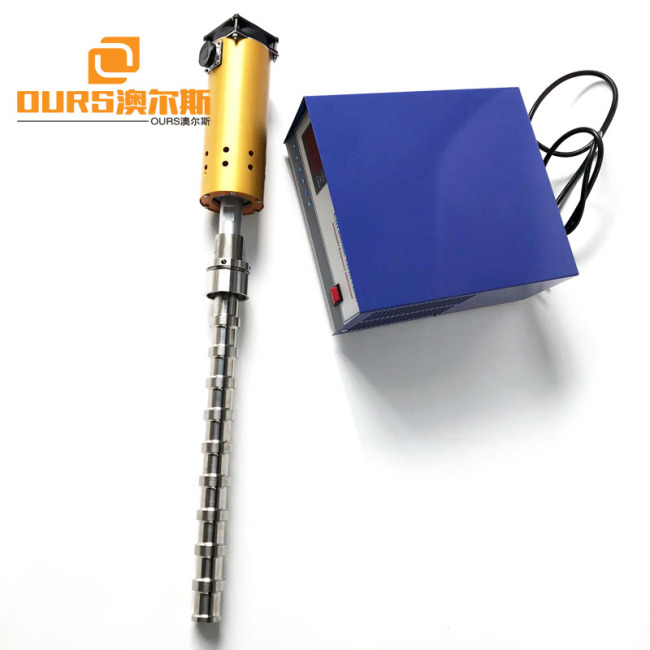

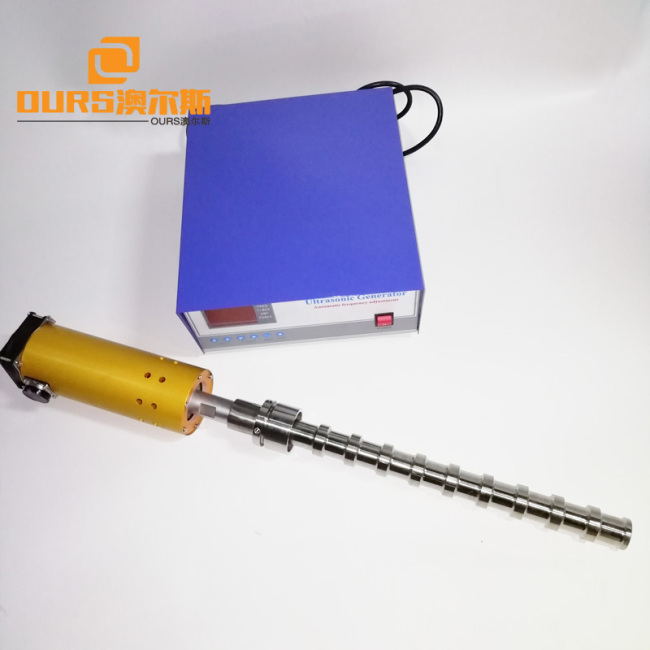

The ultrasonic vibration rod generates radial vibration to the rod body through a high-power large-amplitude transducer, and generates ultrasonic waves uniformly at 360 ° near the vibration rod. Its amplitude is between the ultrasonic cleaner and the processor. Therefore, use The direction is more flexible. The ultrasonic vibrating rod can be used for cleaning any grooved body, and can be placed in any position of the cleaning tank. The volume occupied by the ultrasonic vibration rod is very small and can be used very flexibly. It is used in the interior of the reaction kettle to accelerate dissolution, accelerate the reaction and prevent scaling on the inner wall.

Features of Ultrasonic Cleaner Vibrator:

1. The stronger the ultrasonic power density, the liquid that can not be processed with low power density can be processed;

2. Multiple frequencies are available to solve every problem in various industries;

3. The material adopts GB 304 stainless steel with a thickness of 1.0MM, which is durable and resistant to high temperature;

4. South Korea imported standard 60W industrial-grade shock head, with concentrated intensity and significant cleaning effects;

5, can work continuously for a long time without interruption;

6.With generator control system, flexible operation **;

7, cleaning, emulsification, separation, homogenization, extraction, catalysis, defoaming, stirring, etc .;

8. The power output of the ultrasonic vibrating rod is not affected by load changes such as liquid level, tank capacity and temperature difference, and the power output is stable and uniform.

9. Ultrasonic cavitation is generated around the vibrating rod, and the ultrasonic energy is very evenly distributed around the rod;

10.Ultrasonic vibration rod is sealed and waterproof, safe to use;

11. The ultrasonic vibrating rod is more than 1.5 times the service life of the traditional ultrasonic vibration plate;

The circuit part adopts German advanced energy-saving and environmental protection technology and full-wave working mode. Radial vibration, the ultrasonic wave is generated uniformly 360 ° near the vibrating rod, and its amplitude is between the ultrasonic cleaning machine and the processor, so the direction of use is more flexible. The ultrasonic vibrating rod can be used in any position, and it takes up very little space and can be used very flexibly. Ultrasonic vibration rods are widely used in traditional ultrasonic pretreatment, biochemistry, food, chemical, pharmaceutical and other industries.

In biochemistry, ultrasonic vibrating rods are used in large-scale applications such as emulsification, separation, homogenization, extraction, and catalytic reactions to increase productivity;

In the food industry, ultrasonic vibration rods are used for uniform stirring, which plays an inestimable role in homogeneity;

In the chemical industry, ultrasonic vibration rods are suitable for cleaning pipes, tanks and kettles;

In the process of refining biodiesel from waste oil and palm oil, the catalytic effect of ultrasound is very amazing, and the efficiency is increased by more than ten times. It will have broad development prospects in the petrochemical industry. There are currently more than 40 application cases.

The ultrasonic vibrating rod is mainly used in the cleaning of the inner walls of thick-walled metal pipes, on-line ultrasonic anti-scaling of boilers, ultrasonic cleaning in vacuum / pressure occasions, various pipeline ultrasonic treatments and pipeline sonochemical treatments.

Features:

1. Ultrasonic cavitation is generated around the vibrating rod, and the ultrasonic energy is very evenly distributed around the rod;

2. The power output of the vibrating rod is not affected by load changes such as liquid level, tank capacity and temperature difference, and the power output is stable and uniform;

3. It is more than 1.5 times the service life of the traditional ultrasonic vibration plate;

4. The use condition of the tube vibrating rod is non-acid liquid below 40 degrees; the solid vibrating rod can be used in any occasion, but the effective length will not exceed 700.

5, sealed waterproof, safe to use.

US equipment | Frequency (KHz) | Ultrasound Output(W) | Total Length (mm) | Diameter (mm) | Static Capacity (pF±10%) |

ARS-HLCSB-300 | 20 | 300 | 505 | Φ40-50 | 68000 |

ARS-HLCSB-600 | 20 | 600 | 587 | Φ40-50 | 68000 |

ARS-HLCSB-900 | 20 | 900 | 628 | Φ40-50 | 68000 |

ARS-HLCSB-1500 | 20 | 1500 | 793 | Φ40-50 | 68000 |

ARS-HLCSB-2000 | 20 | 2000 | 793 | Φ40-50 | 132000 |

1500W 20KHZ Industrial Design Ultrasonic Material Dispenser Ultrasonic Reactor Supplier

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian