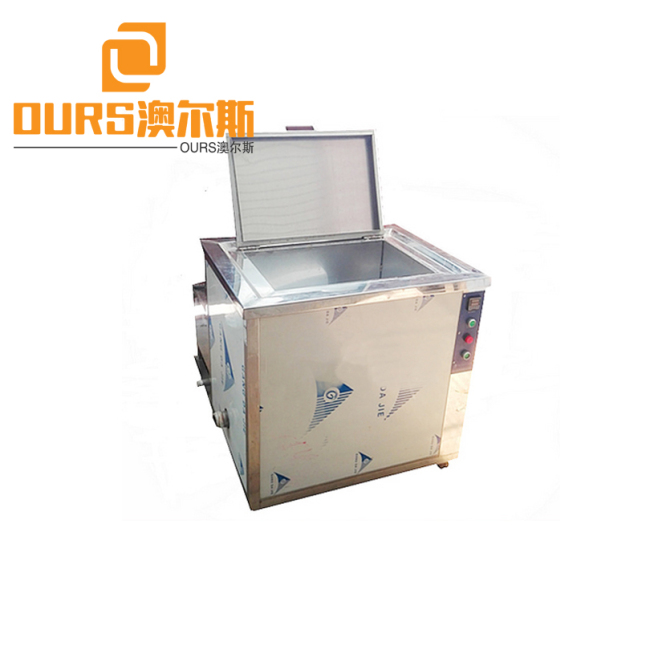

1500W Multi Tank Machine Ultrasonic Cleaner For Cleaning Engine Parts

1-4 Set

$2,850.00

≥ 5 Set

$2,650.00

- Item No.1500w/40khzMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

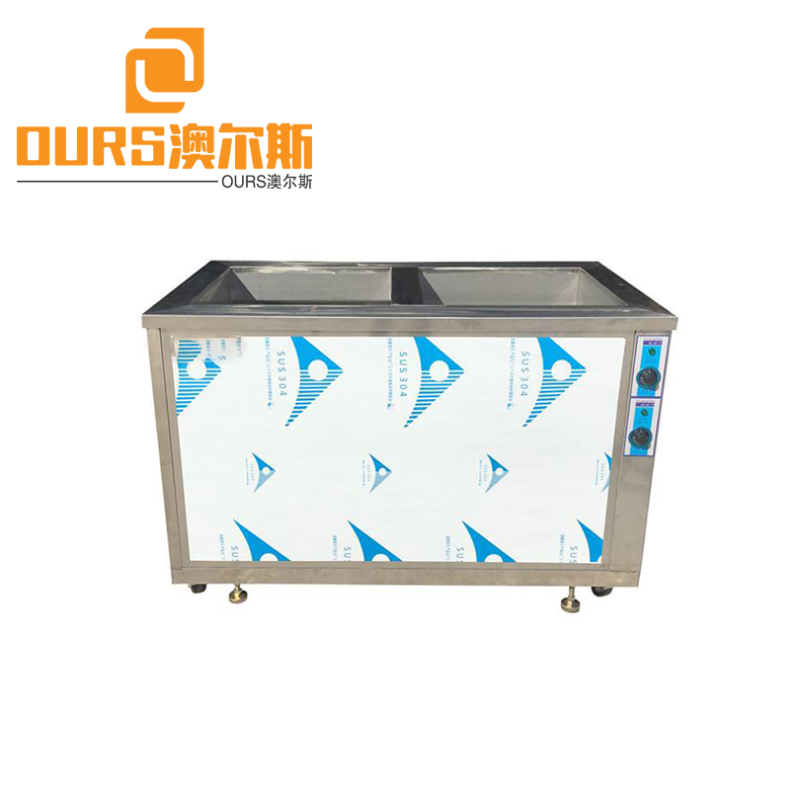

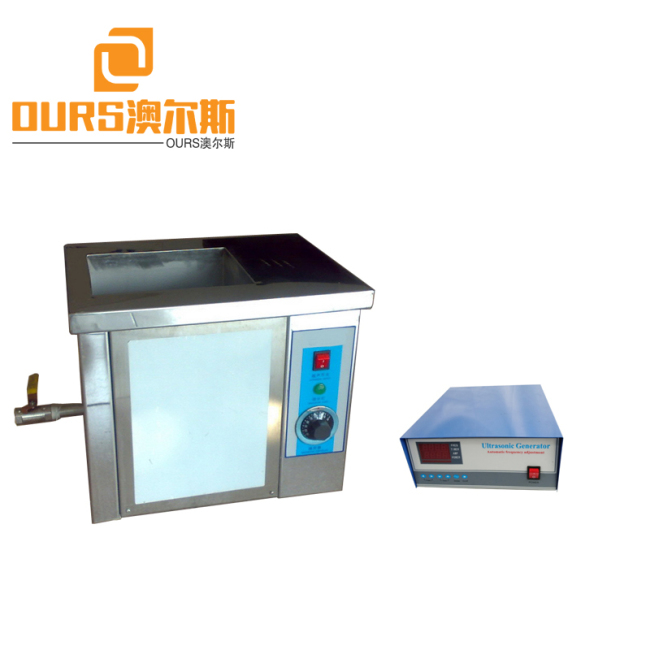

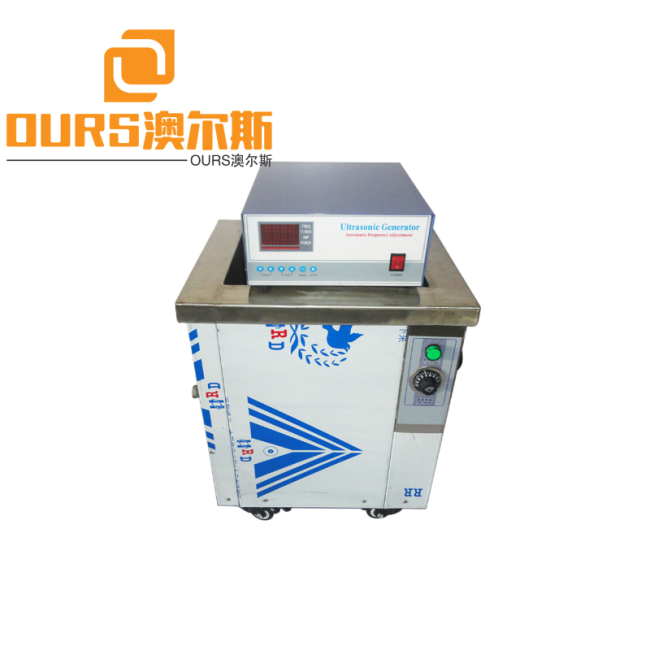

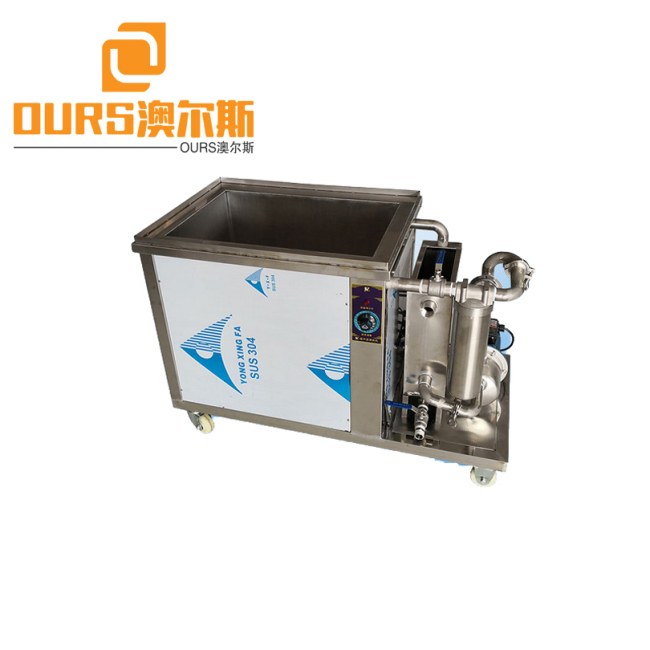

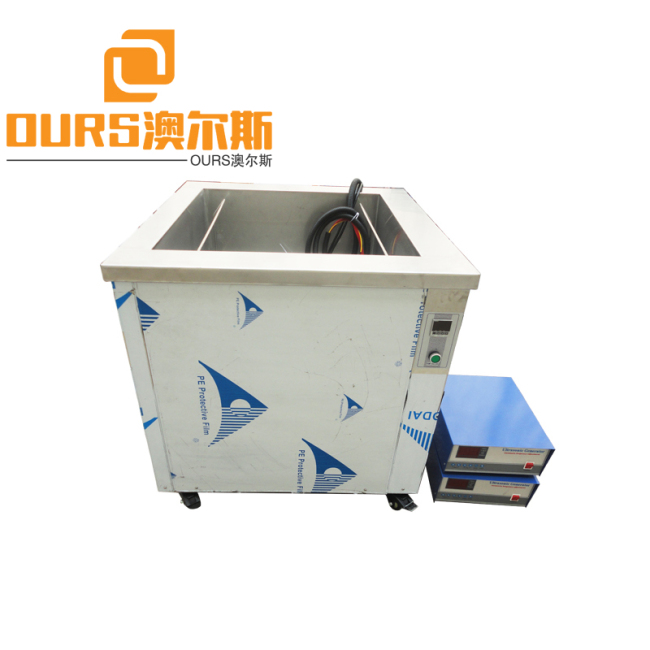

1500W Multi Tank Machine Ultrasonic Cleaner For Cleaning Engine Parts

The principle and knowledge of how the multi-tank ultrasonic cleaner works. The principle of ultrasonic cleaning machine is mainly to convert the sound energy of the power ultrasonic frequency source into mechanical vibration through the transducer, and radiate the cleaning liquid in the tank to ultrasonic waves through the cleaning tank wall. Due to the radiated ultrasonic waves, the microbubbles in the liquid in the tank can maintain vibration under the action of sound waves.

When the sound pressure or sound intensity reaches a certain level, the bubble will expand rapidly and then suddenly close. During this process, the shock wave is generated at the moment when the bubble is closed, causing a pressure of 1012-1013pa and local temperature adjustment around the bubble. The huge pressure generated by this ultrasonic cavitation can destroy insoluble dirt and make them differentiate in the solution. The direct and repeated impact of steam-type cavitation on dirt.

On the one hand, it destroys the adsorption of the dirt and the surface of the cleaning part, and on the other hand, it can cause the fatigue damage of the dirt layer and be dismissed. The vibration of the gas bubble scrubs the solid surface. Once the dirt layer is cracked, the bubbles are immediately " The “drilling” vibration causes the dirt layer to fall off. Due to cavitation, the two liquids are rapidly dispersed and emulsified at the interface. When the solid particles are wrapped in oil and adhere to the surface of the cleaning part, the oil is emulsified and the solid particles fall off by themselves. When it propagates in the cleaning liquid, it will produce positive and negative alternating sound pressure, forming a jet, which impacts the cleaning part. At the same time, due to the nonlinear effect, it will produce acoustic and micro-acoustic flow. Ultrasonic cavitation will produce high-speed at the solid-liquid interface. Microjets, all of these effects, can destroy dirt, remove or weaken the boundary dirt layer, increase stirring and diffusion, accelerate the dissolution of soluble dirt, and strengthen the cleaning effect of chemical cleaning agents. It can be seen that any place where the liquid can be immersed and the sound field has a cleaning effect, and its characteristics are suitable for cleaning parts with very complicated surface shapes. Especially after adopting this technology, the amount of chemical solvents can be reduced, thereby greatly reducing environmental pollution.

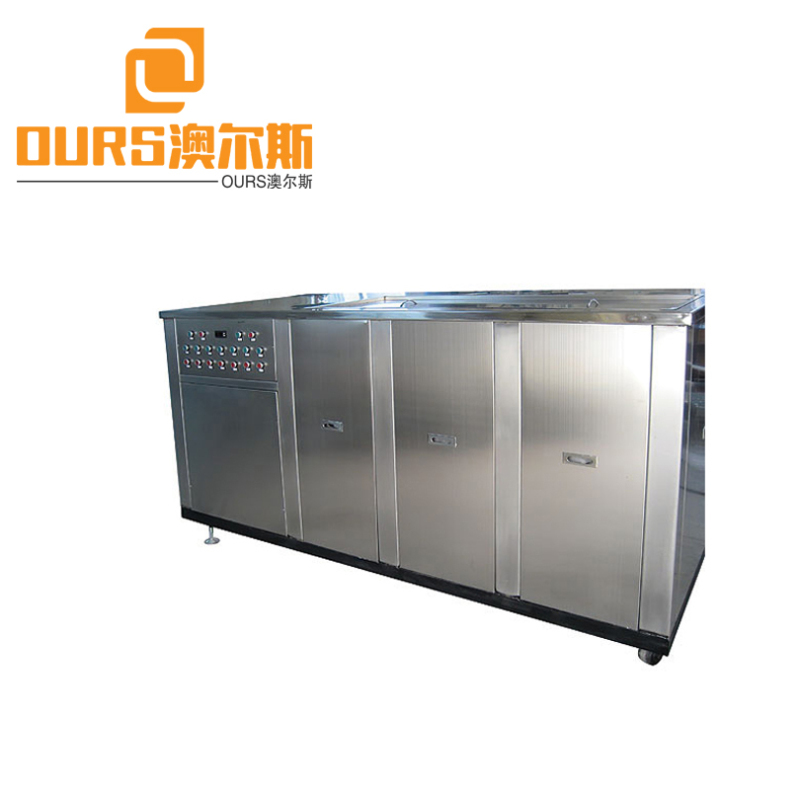

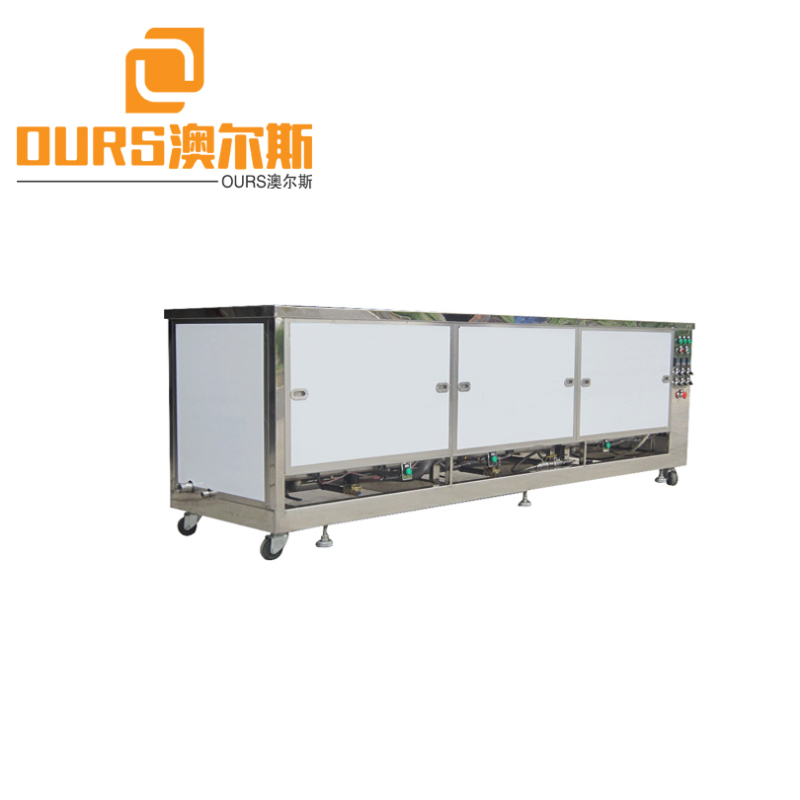

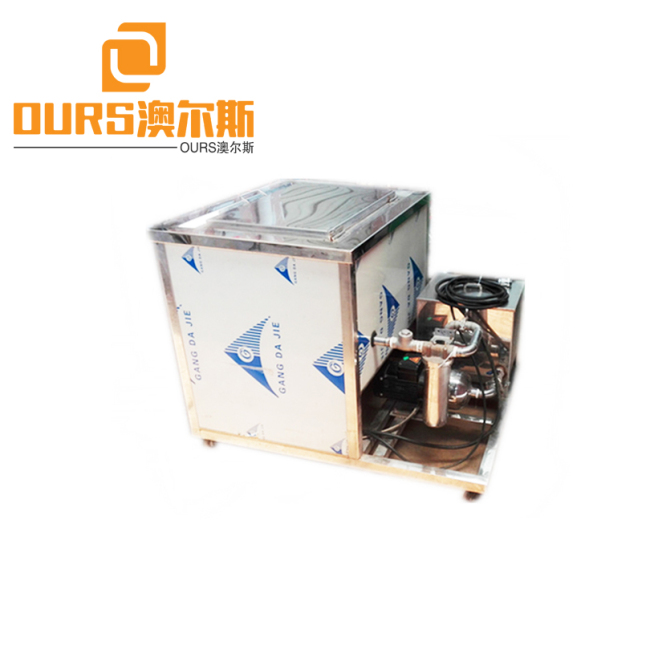

Multi-tank ultrasonic cleaning machine is a three-tank multi-station cleaning machine, which is a new generation of environmentally friendly cleaning machine specially designed for electroplating and painting pretreatment. Any combination of multiple processes such as ultrasonic cleaning, rinsing, spraying, and drying can be selected. This machine adopts a new generation of water-based environmental protection solution, no erosion, no pollution, better cleaning effect, so that the electroplating layer and spray paint layer are more reliable. It can also be equipped with an automatic hoisting transmission device according to user requirements, which is safer, more reliable and faster to clean the workstation.

Ultrasonic washing and cleaning machine is a special feature of our company's connected machines, which are important in industries such as monocrystalline silicon wafers, electronic parts, optical lenses, small hardware and I-machined compact parts. 3-tank ultrasonic washing machine system This series of washing has the following characteristics:

1. Fully stainless steel layout, beautiful appearance and layout.

2. Set the liquid level safely to ensure normal operation of the equipment.

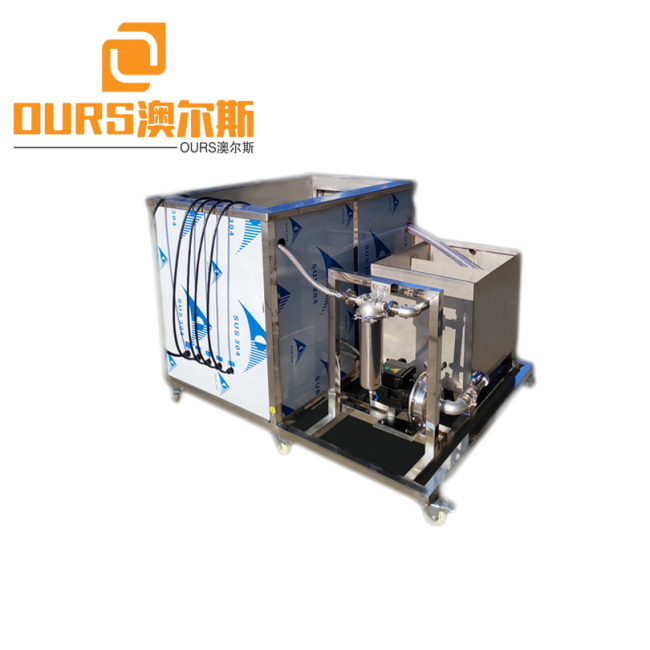

3. Set up a filtration system to ensure the cleanliness of the solution.

4. Heating and active constant temperature system, the constant temperature scale is 20℃-90℃ (adjustable).

5. Use water to heat an appropriate agent as a washing solution, with low cost and mature technology.

6. The weird overflow plan ensures that there is a sufficient water level and the dirt floating on the water surface is constantly overflowed.

product description:

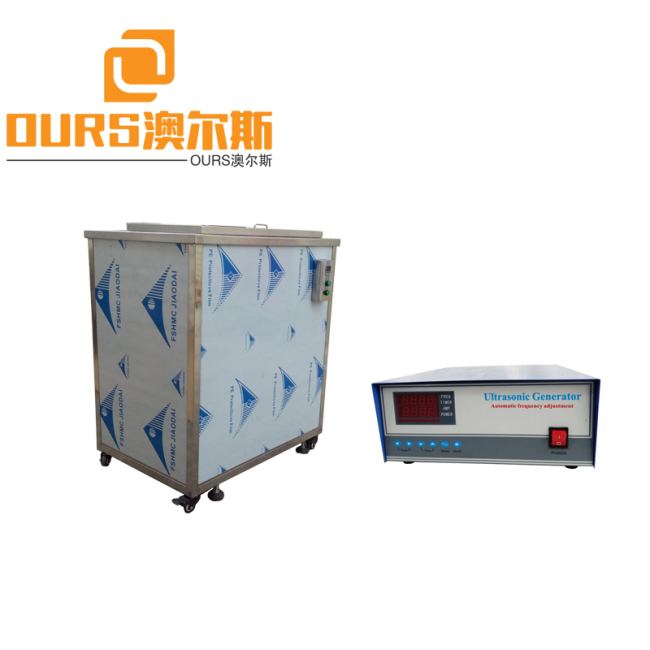

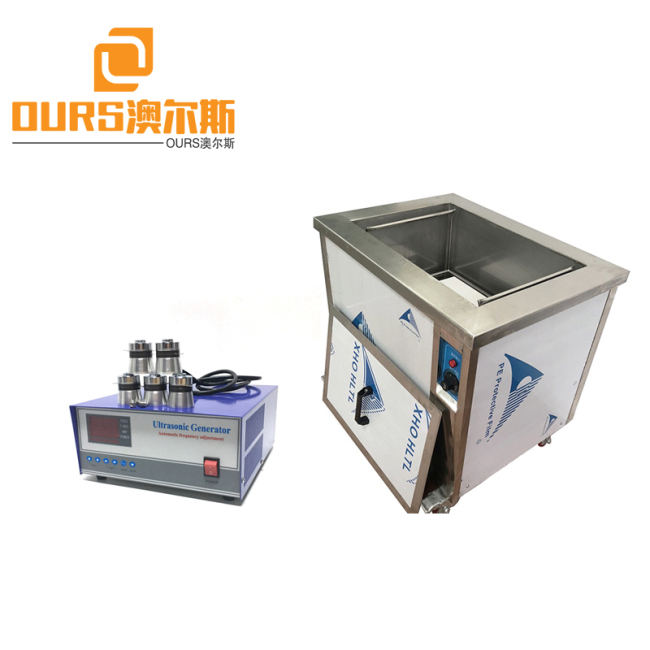

1. Adopt good technology with sandblasting and Swiss glue bonding process, adopt German Siemens IGBT as the core component, long service life, high ultrasonic power conversion efficiency, strong power, and good cleaning effect.

2. The inner tank is made of SUS304 2.0 welding, and is equipped with overflow ports, slag tanks, sealing covers, etc. according to customer needs.

3. The built-in concealed heating tube is used for rapid heating and reliable temperature control. The temperature control adopts a digital temperature controller with PID adjustment function. It has the advantages of high control accuracy, small temperature overshoot, energy saving and consumption reduction, intuitive display and simple operation. Automatic temperature Control RT-100℃ adjustable.

The main application scope of multi-slot ultrasonic cleaning machine:

1. Automobile maintenance and repair industry: automobile engine, medium truck engine, automobile and motorcycle accessories and high-pressure valves, oil pumps, nozzles, cylinder heads, variable boxes, parts and other anti-rust grease removal, degreasing and rust removal of mechanical parts, Cleaning of engine, carburetor and auto parts, dredging and cleaning of filters and screens, etc.

2. Surface treatment industry: degreasing and rust removal before electroplating, cleaning before ion plating, phosphating treatment, removal of carbon deposits, removal of oxide scale, removal of polishing paste, surface activation treatment of metal workpieces, etc.

3. Instrumentation industry: cleaning of measuring tools, high-cleanliness cleaning before assembly of parts, etc.

4. Electronic industry: Removal of rosin and solder spots on printed circuit boards; cleaning of mechanical and electronic parts such as high voltage contacts.

5. Medical industry: cleaning, disinfection and sterilization of medical equipment, cleaning of laboratory utensils, etc.

6. Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

7. Watches, jewelry industry: remove sludge, dust, oxide layer, polishing paste, etc.

8. Chemical and biological industries: cleaning and descaling of laboratory utensils.

Type | Frequency (Khz) | Power(W) | Capacity(L) |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1500 | 30 |

ARS-MJQXJ-50LTT | 28KHZ,40KHZ | 2500 | 50 |

ARS-MJQXJ-70LTT | 28KHZ,40KHZ | 3500 | 70 |

1500W Multi Tank Machine Ultrasonic Cleaner For Cleaning Engine Parts

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian