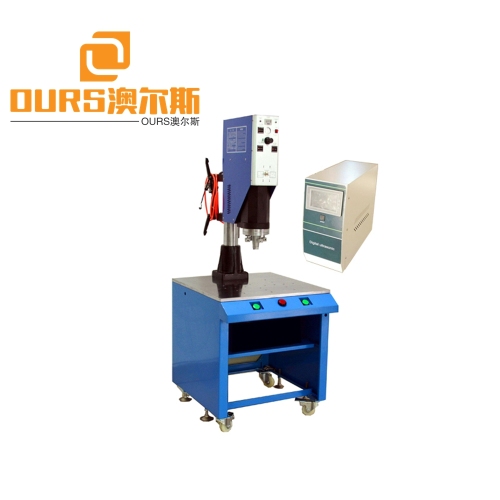

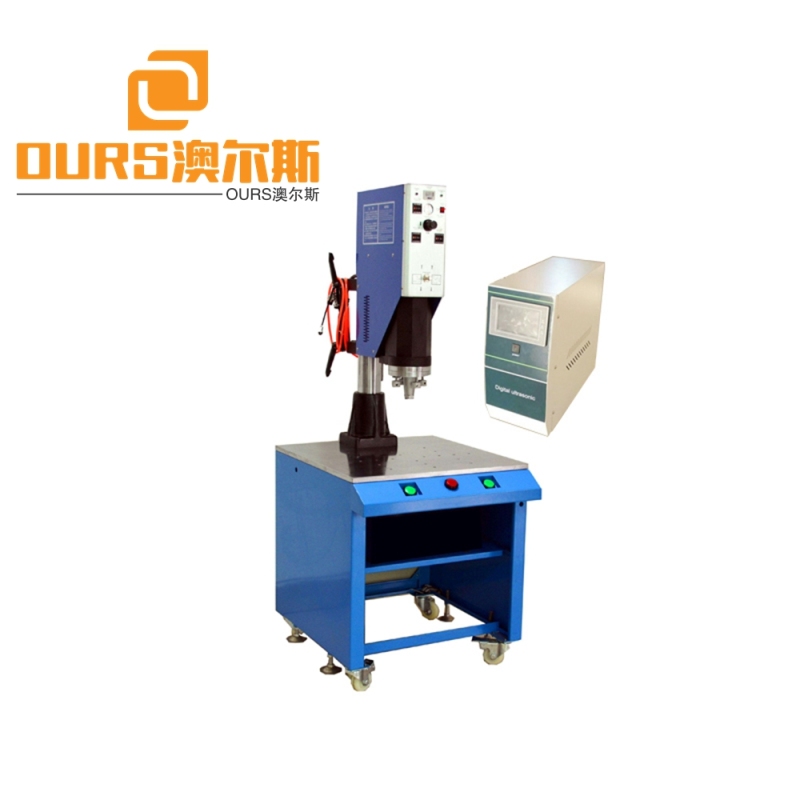

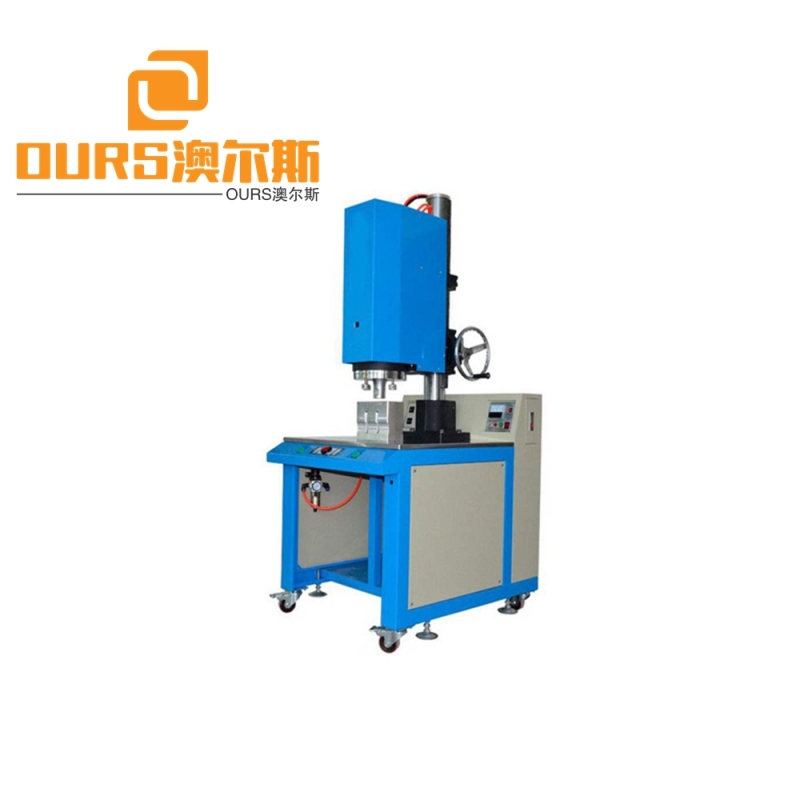

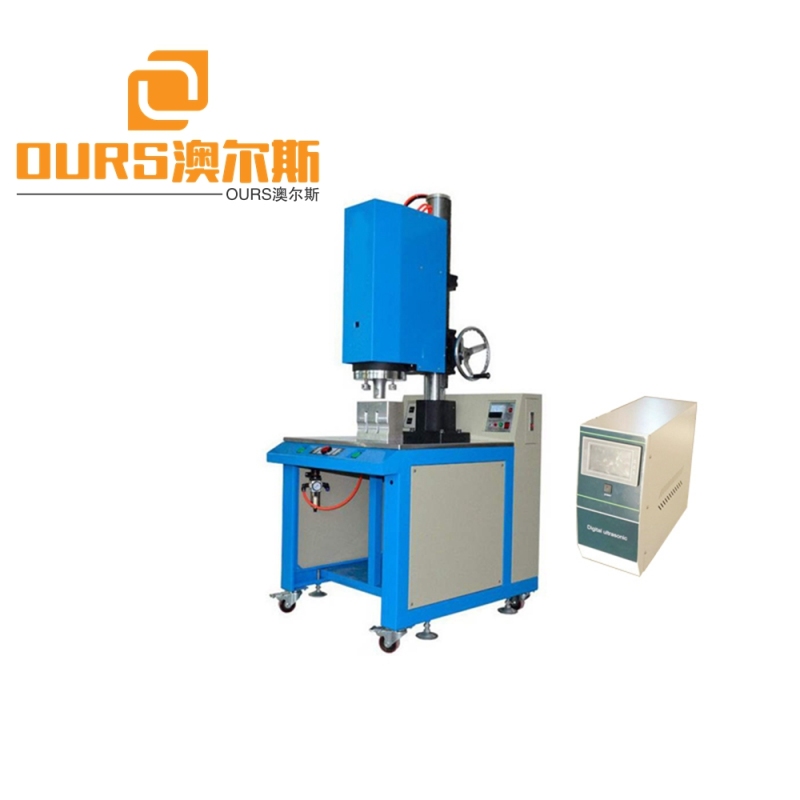

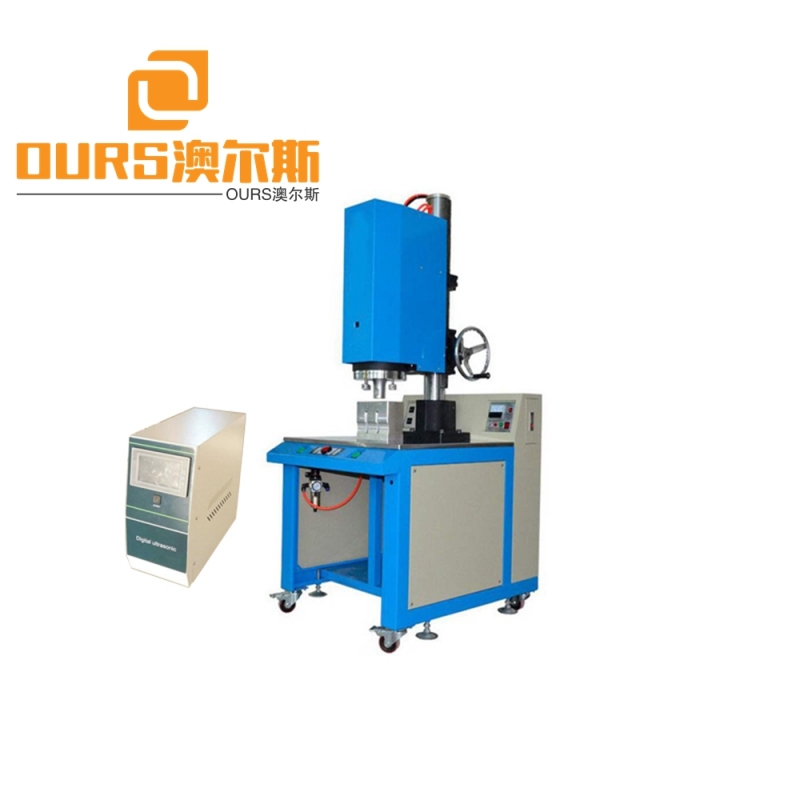

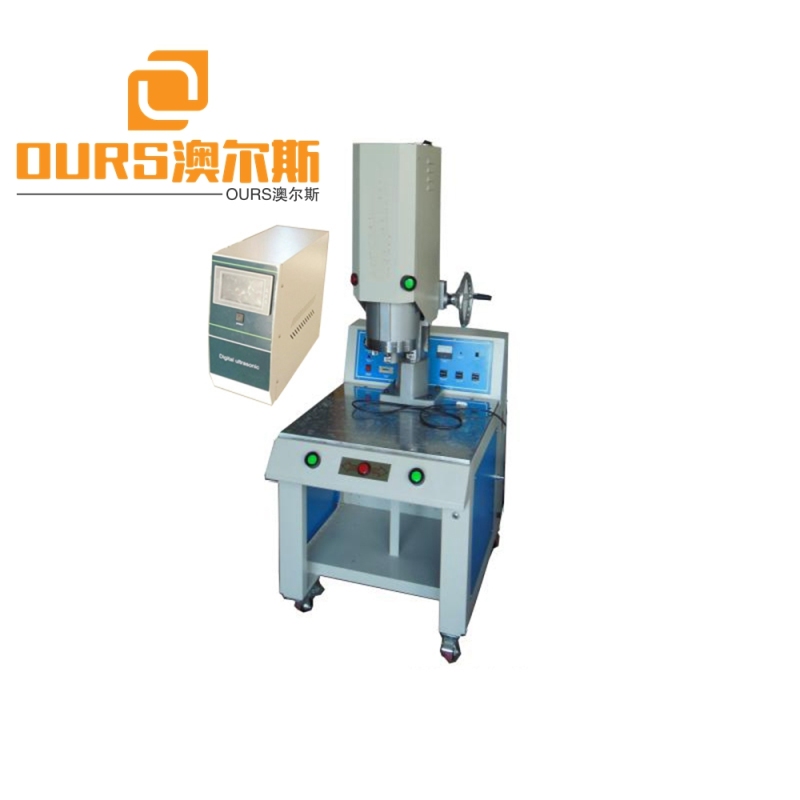

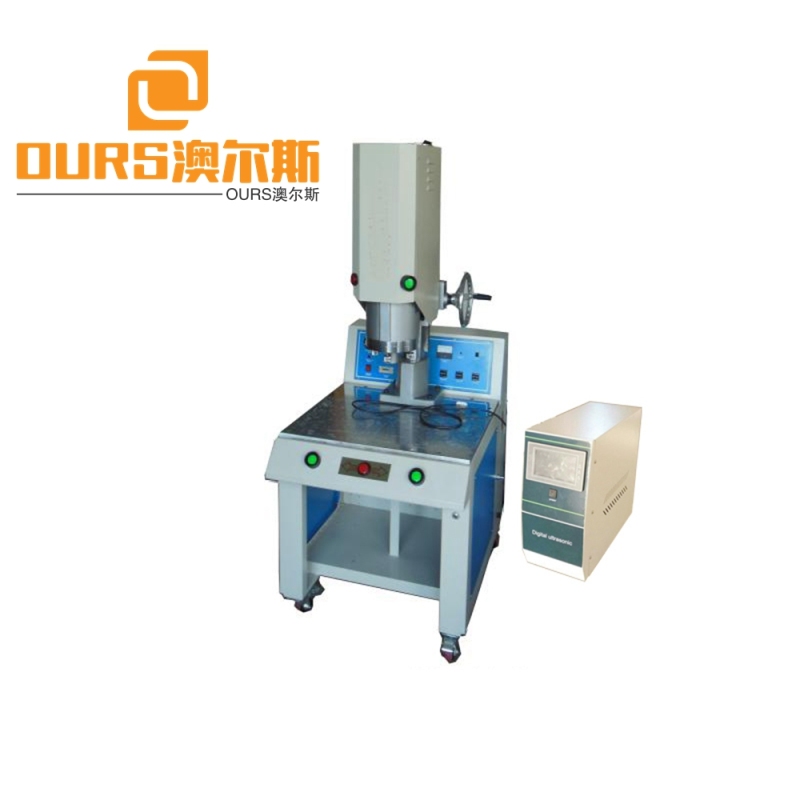

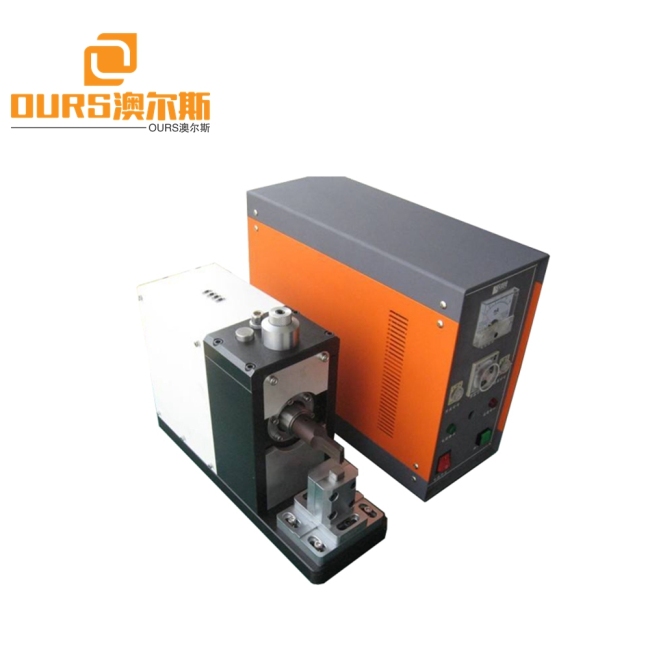

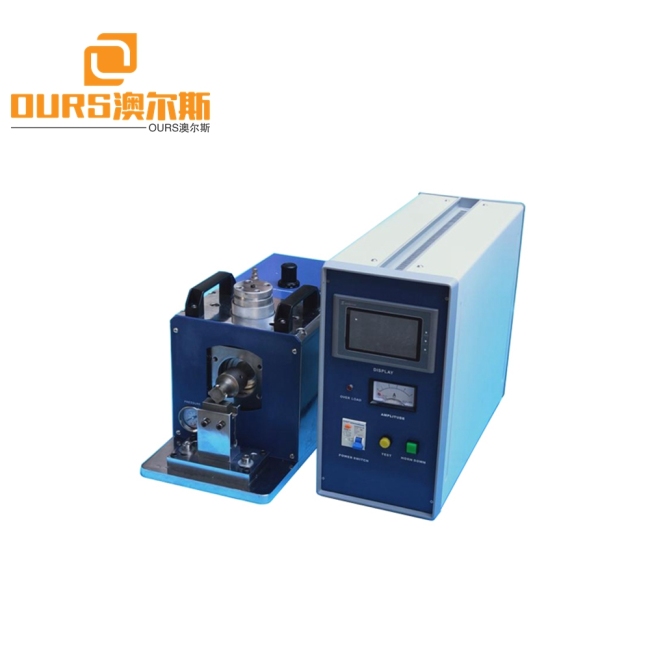

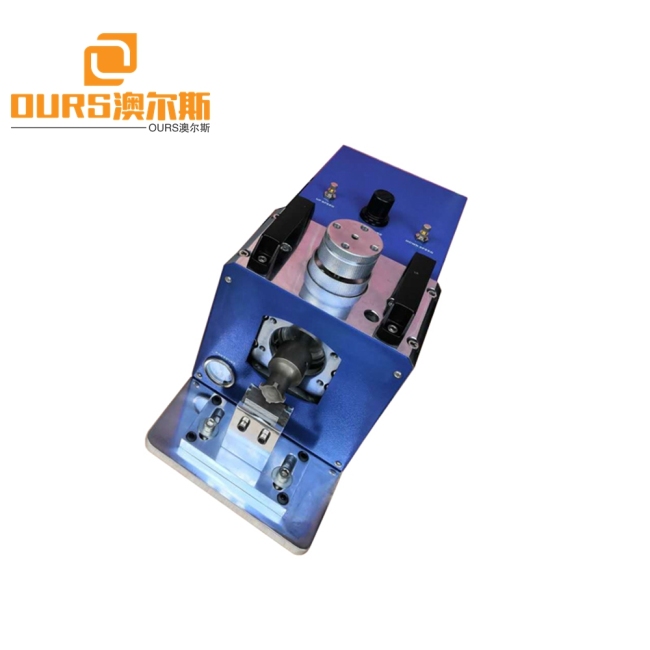

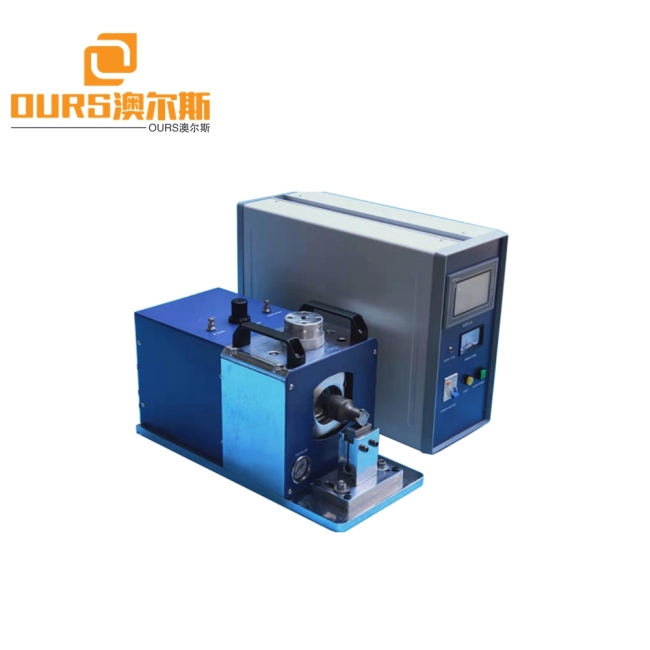

15khz 4200w Ultrasonic Welding Machine For Welding of Phone/Computer Keyboard

≥1 Set

$3,500.00

- Item No.ARS-SLHJ-4200W15MOQ1 Set

- Product size200 x 100 x 90 cmProduct weight250 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

The larger the area of the ultrasonic plastic welding seam, the greater the dispersion of high-frequency vibration energy, and the welding effect will become unable to achieve the welding effect. In fact, the ultrasonic longitudinal propagation principle, the greater the distance, the more energy is lost. The ultrasonic welding seam should be controlled within 6 cm, and the welding line should be controlled within 30-80 wire. The thickness of the plastic part is greater than 2 mm for perfect results. , Different products are equipped with different ultrasonic plastic welding.

When ultrasonic welding plastic products, you must know the melting points of different plastics. Through reasonable welding seam design and welding time setting, the product welding seam reaches the specified melting point temperature, so that a certain pressure is applied, and the product seam position welding is completed. If the welding temperature of the plastic product is not reached, the welding will fail.

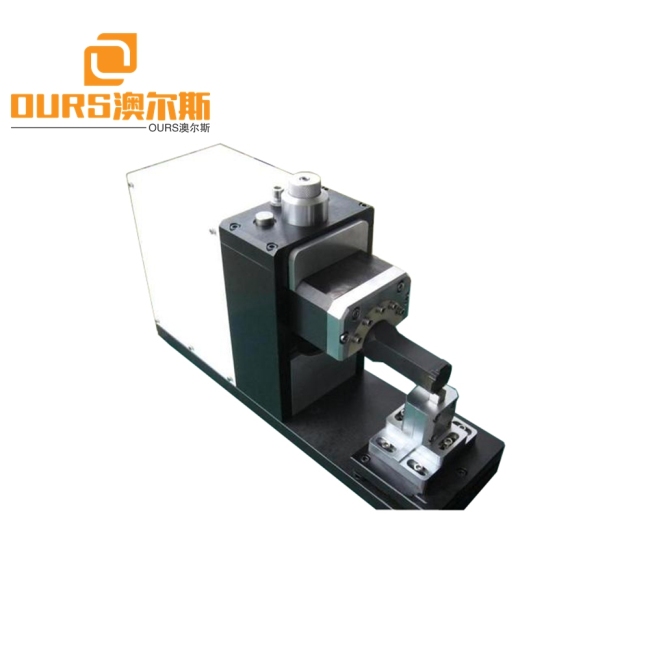

Ultrasonic plastic welding machine

Ultrasonic welding heads are simulated and verified by computer software, and those that meet the welding requirements of the products are processed by high-tech masters. Rigorous design and inspection process is an important matter for welding joints and a basic requirement for the quality of plastic products.

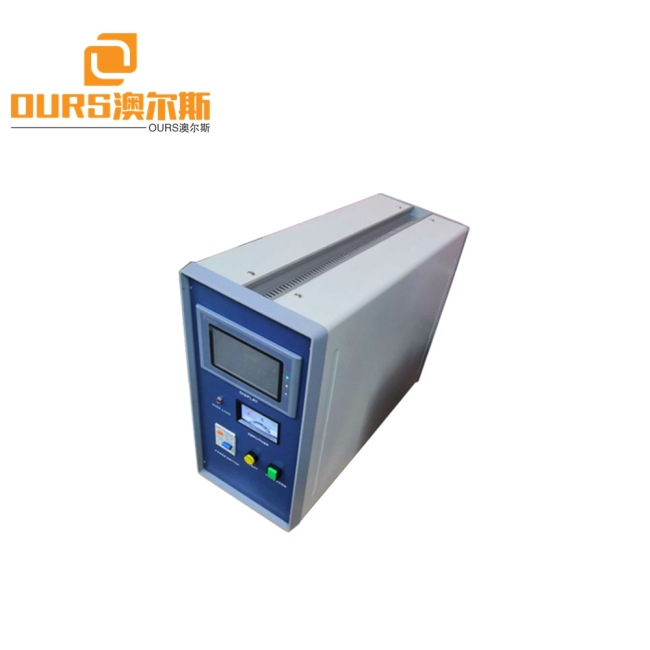

Plastic products of different materials are ultrasonic welding machines with different output powers. This can reduce the time of adjusting the machine and reduce the problems caused by human error. You can use the ultrasonic automatic frequency tracking welding machine to reduce most of the problems. The automatic frequency adjustment function makes Ultrasonic plastic welding machine is more convenient to use.

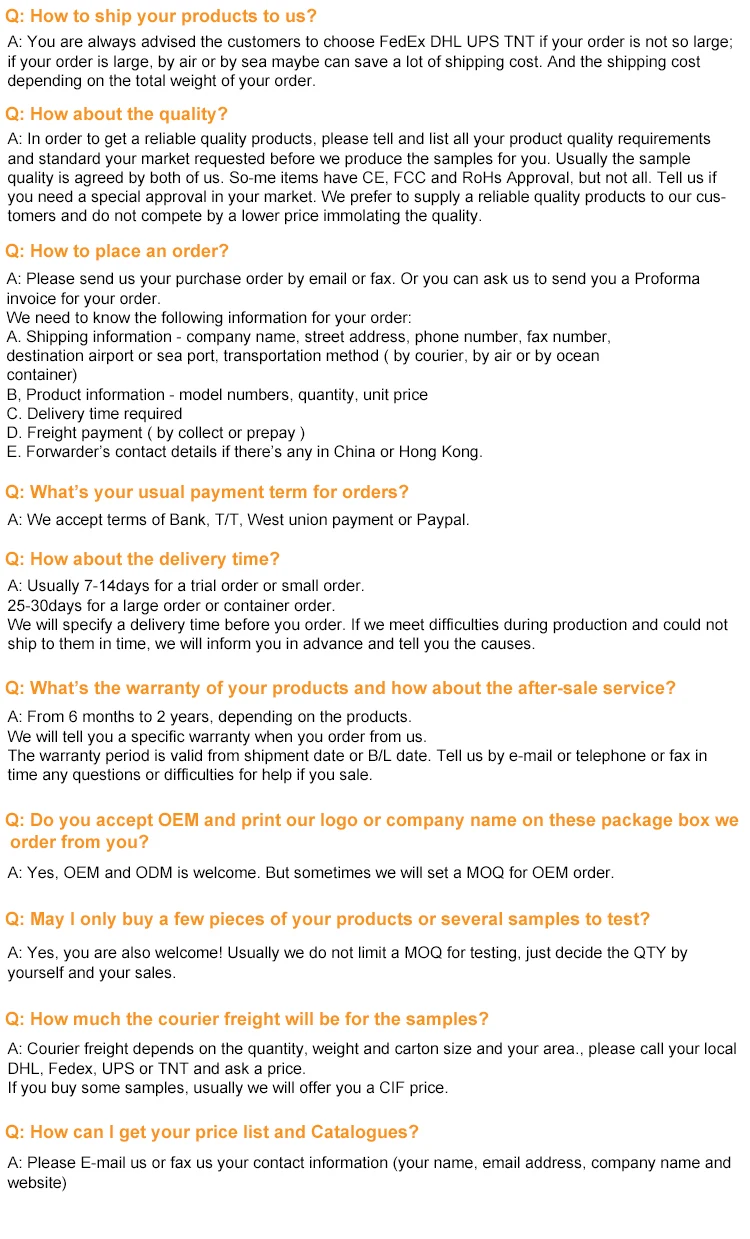

Type | Power(W) | Frequency (KHz) |

ARS-SLHJ-1500W15 | 1500W | 15KHZ |

ARS-SLHJ-1500W20 | 1500W | 20KHZ |

ARS-SLHJ-1800W15 | 1800W | 15KHZ |

ARS-SLHJ-1800W20 | 1800W | 20KHZ |

ARS-SLHJ-2000W15 | 2000W | 15KHZ |

ARS-SLHJ-2000W20 | 2000W | 20KHZ |

ARS-SLHJ-2600W15 | 2600W | 15KHZ |

ARS-SLHJ-2600W20 | 2600W | 20KHZ |

ARS-SLHJ-3200W15 | 3200W | 15KHZ |

ARS-SLHJ-4200W15 | 4200W | 15KHZ |

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian