2000W 20KHZ High Efficient Ultrasonic Welding Of Plastic Battery Cases

1-9 Set

$9,650.00

≥ 10 Set

$9,500.00

- Item No.20201116e6b77MOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

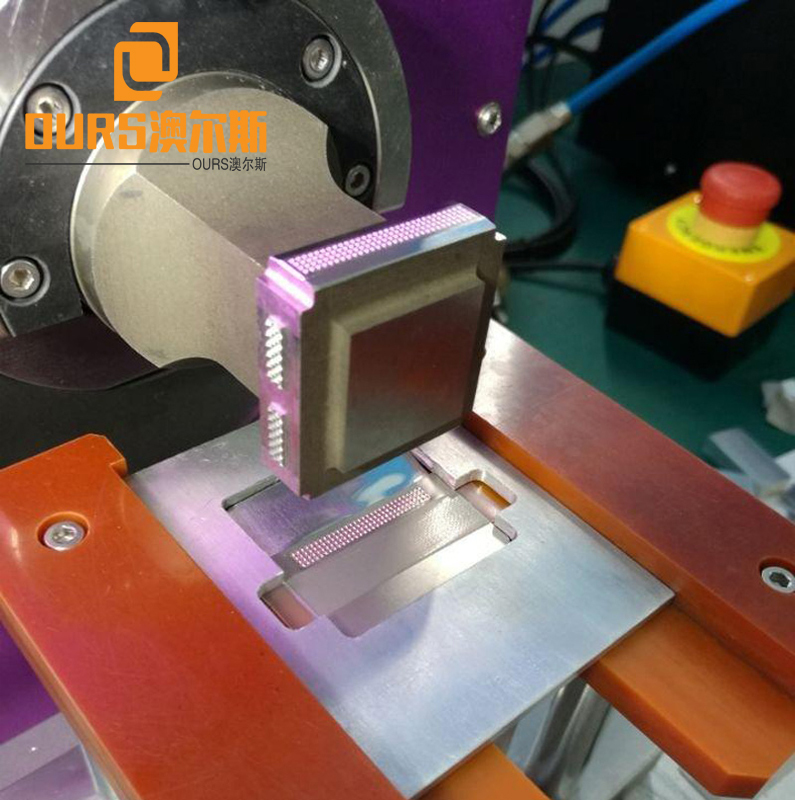

2000W 20KHZ High Efficient Ultrasonic Welding Of Plastic Battery Cases

![]()

Application of plastic welding equipment:

Ultrasonic plastic welding machine is used in automotive industry, electronics industry, medical industry, home appliance industry, non-woven clothing, office supplies, packaging industry, toy industry, etc. Such as car body plastic parts, car doors, car instrumentation, headlights and mirrors, sun visors, interior parts, filters, reflective materials, road studs, bumpers, cables, plastic filters for motorcycles, heat dissipation Devices, brake fluid tanks, oil cups, water tanks, fuel tanks, ducts, exhaust purifiers, tray filter plates; plastic electronics: pre-paid water meters, communication equipment, cordless phones, mobile phone accessories, mobile phone cases, battery cases, chargers , Valve-regulated sealed maintenance lead-acid battery, 3 inch floppy disk, U disk, SD card, CF card, USB connector, Bluetooth; toy stationery: folders, photo albums, folding boxes, PP hollow boards, pen covers, ink cartridges, toner cartridges; Medical daily use: watches, kitchen utensils, oral liquid bottle caps, drip bottle caps, mobile phone accessories, Jinrou brushes, daily necessities, sanitary products, children's products, air mattresses, hangers, garden supplies, kitchen ware, Jinrou brushes, Welding of shower head, anti-counterfeit bottle cap, cosmetic bottle cap, coffee pot, washing machine, air dehumidifier, electric iron, electric kettle, vacuum cleaner, speaker metal cover, etc.

Principle of plastic welding equipment:

The ultrasonic energy is transmitted to the welding zone through the upper welding piece. Because the welding zone is the interface between the two weldings, the acoustic resistance is large, so local high temperature will be generated. Due to the poor thermal conductivity of the plastic, it will not be released in time, and will gather in the welding zone. The contact surfaces of the two plastics melt rapidly, and after a certain pressure is applied, they are fused into one. When the ultrasonic wave stops working, the pressure is allowed to continue for a few seconds, so that it solidifies and forms, so that a strong molecular chain is formed to achieve the purpose of welding, and the welding strength can be close to the strength of the raw material.

Features of the whole machine

1. casting aluminum alloy base, super thick seamless steel pipe column, rigid, no deformation under pressure.

2. with current overload protection, adjust the machine easily and conveniently.

3. original Japanese piezoceramic transducer, Huang steel alloy ultrasonic horn.

4. electronic frequency tracking, integrated alphabet circuit board

The advantages of automatic frequency tracking ultrasonic welding machine:

1, the manual frequency regulation is not convenient, automatic detection frequency is activated, and it is more convenient and simple to use.

2. The built-in parameters are digitized by computer, and the amplitude is automatically compensated. The amplitude and power of the load are magnified synchronously when the load is heavier. Thus, the transducer and the welding head die are effectively protected, and the welding precision is higher.

3, the power output adopts the digital stepless linear regulation. The output power is selected freely from 50% to 100%. The full bridge IGBT module is used to enlarge the internal power. The ultrasonic conversion rate is high and the maximum ultrasonic power can reach 7200W, which can meet the requirements of all kinds of welding.

4, more advanced protection circuit, output acoustic wave overload, die sudden rupture overload, built-in computer detection circuit in a very short time cut out the output, thus protecting the internal circuit;

5. High speed handover of up to 135 times per minute can be used to weld various non-standard automation equipment.

6, the operation interface can be selected in Chinese or English, and foreign purchasing is more convenient.

7, the electric box control wiring is very simple, the rear two air plug, the 30MM2 foot of the sound wave output, the 25MM7 foot starting switch and the quick stop switch, plug in the power can work; electric box volume smaller

Application

Used for toys, electronic, plastic bags and small rubber pieces of welding and forming.

Ultrasonic Welding designed for ABS/PE/PC/PS/PVC/PP material Ultrasonic welding;

ABS-PC complex welding,acrylic Ultrasonic welding etc,can weld the series products as below:

1.Toy Industry : toy gun, telephone, rag baby, general plastic toys.

2. Electronics: Glue watchcase, nylon strap, computer, sound box bag shell, mobile phone battery

3. Light industry: Rear lamp, cornering lamp, averting mirror, etc.

4. Packing industry: Cosmetic box, PVC box, toothpaste tubes, etc.

5. General commercial products: Typewriter ribbon, video box, tape box, computer disks, etc.

Type | Power(W) | Frequency (KHz) |

ARS-SLHJ-800W35 | 800W | 35KHz |

ARS-SLHJ-800W40 | 800W | 40KHz |

ARS-SLHJ-900W20 | 900W | 15KHz |

ARS-SLHJ-900W20 | 900W | 20KHz |

ARS-SLHJ-1000W35 | 1000W | 40KHz |

ARS-SLHJ-1500W15 | 1500W | 15KHZ |

ARS-SLHJ-1500W20 | 1500W | 20KHZ |

ARS-SLHJ-1800W15 | 1800W | 15KHZ |

ARS-SLHJ-1800W20 | 1800W | 20KHZ |

ARS-SLHJ-2000W15 | 2000W | 15KHZ |

ARS-SLHJ-2600W15 | 2600W | 15KHZ |

ARS-SLHJ-2600W20 | 2600W | 20KHZ |

ARS-SLHJ-3200W15 | 3200W | 15KHZ |

ARS-SLHJ-4200W15 | 4200W | 15KHZ |

![]()

2000W 20KHZ High Efficient Ultrasonic Welding Of Plastic Battery Cases

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian