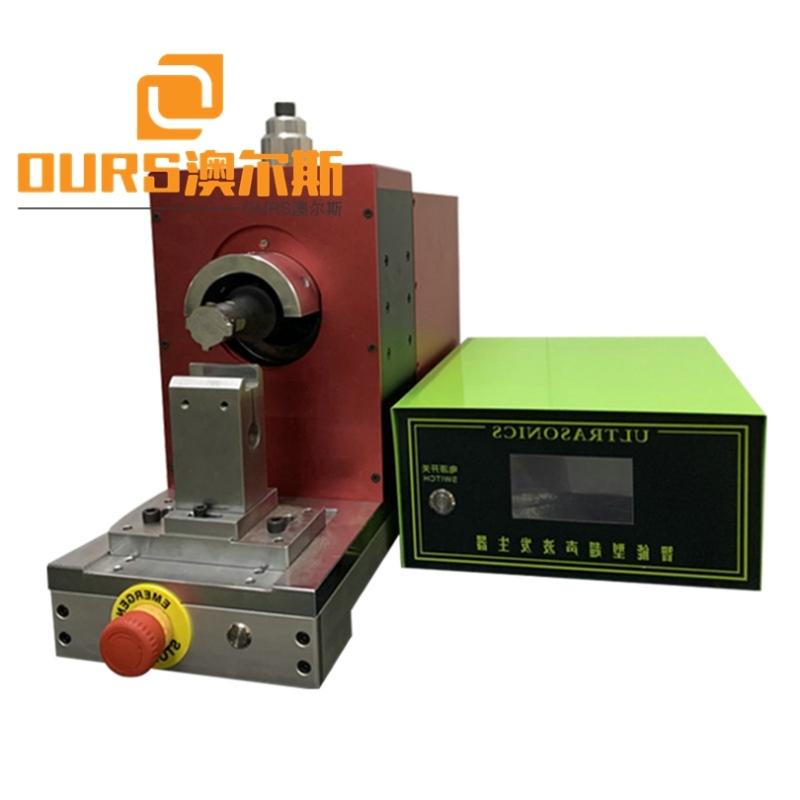

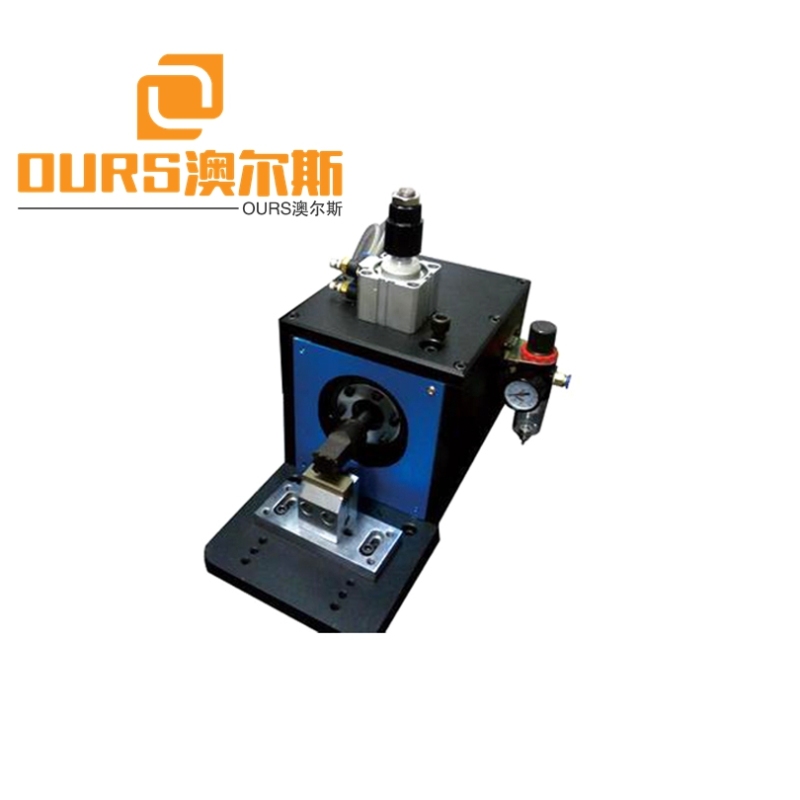

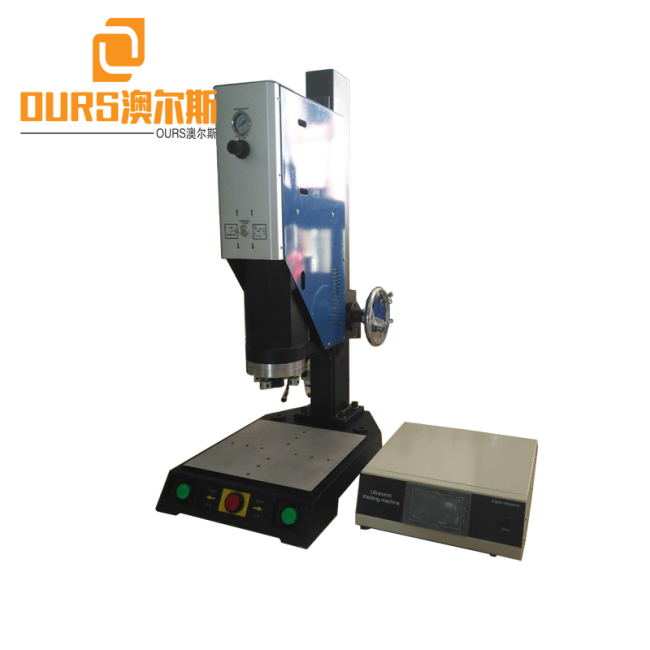

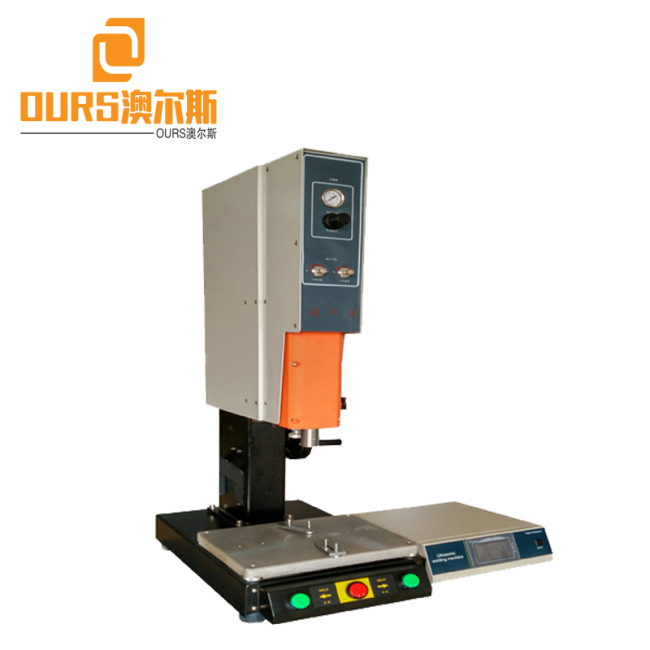

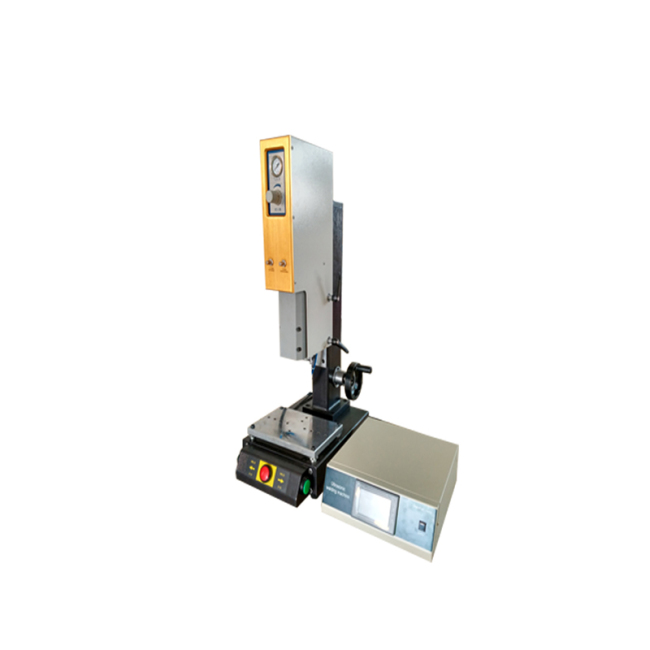

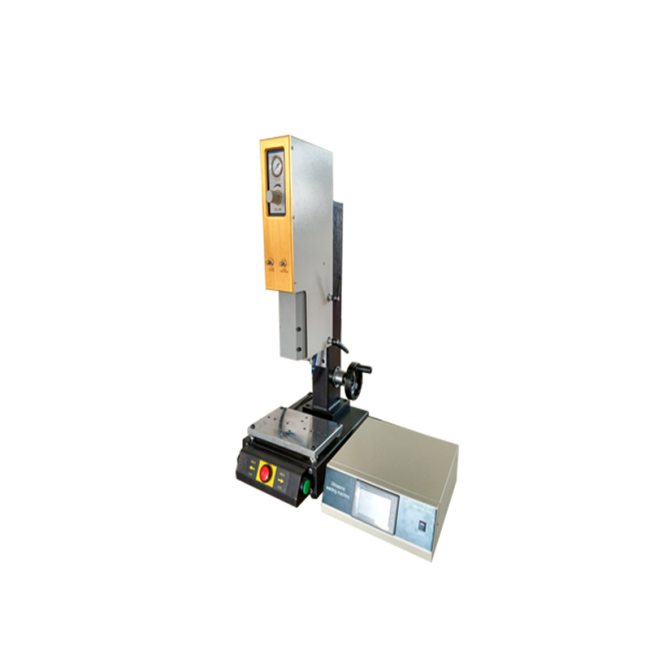

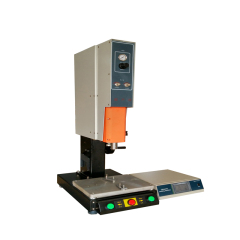

2000W 20KHZ Ultrasonic Metal Welding Equipment For Welding Auto Parts

1-9 Set

$9,850.00

≥ 10 Set

$9,500.00

- Item No.2021072469b7eMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

2000W 20KHZ Ultrasonic Metal Welding Equipment For Welding Auto Parts

![]()

Ultrasonic spot welding machine, ultrasonic metal welding machine, ultrasonic metal spot welding machine, ultrasonic welding machine, aluminum-nickel welding machine, polymer battery positive electrode spot welding machine, lithium battery negative electrode spot welding machine, aluminum to nickel spot welding machine, amorphous silicon Spot welding machine etc.

Features of metal welding

There is no need for flux and external heating, no deformation due to heating, no residual stress, and low requirements for pre-welding treatment on the surface of the weldment. Not only the same kind of metal, but also dissimilar metals can also be welded. It is possible to weld thin sheets or filaments to thick plates. Ultrasonic welding of good conductors has much less energy than current welding, and is often used for welding transistors or integrated circuit leads. When used for sealing welding of drugs and explosive materials, it can prevent general welding from contaminating drugs due to dissolved objects, and will not explode due to heat.

Working principle and characteristics

1. Ultrasonic metal welding machine uses the principle of ultrasonic high-frequency vibration friction to convert the energy of ultrasonic vibration into frictional energy and transfer it to the metal surface to be welded. When friction generates heat and pressure is applied to it, the metal structure molecule Fully activated to form a new type of device for fusion between molecular layers.

2. Features:

Microcomputer control, electronic tuning frequency, LCD display, continuously adjustable power, simple operation, stable and reliable work; firm welding, good consistency, weldment has the characteristics of firm welding surface, high strength, beautiful appearance, and environmental protection. Easy to operate, built-in electronic protection circuit, safe to use, used for similar welding of metals, can perform single-point or multi-point welding on non-ferrous metals; widely used in battery and hardware products industries.

Ultrasonic wave metal spot welder: it is similar to friction welding, but has some differences. The ultrasonic welding time is very short, and the temperature is lower than recrystallization. It is also different from pressure welding, because the static pressure is much smaller than pressure welding. It is generally believed that in the initial stage of ultrasonic welding process, the tangential vibration can remove the oxide on the metal surface, which is the process of repeated micro welding and damage of the protruding part of the rough surface, resulting in the increase of the contact area, the increase of the temperature of the welding area, and the plastic deformation at the interface of the weldment. In this way, under the action of contact pressure, when they are close to the distance where atomic gravity can act, the solder joint is formed. If the welding time is too long or the ultrasonic amplitude is too large, the welding strength will decrease or even damage. Ultrasonic metal welding machine is an advanced high-tech equipment which converts high-frequency electric energy into mechanical vibration energy through transducer and acts on the workpiece, generating high-frequency friction between the two workpiece surfaces until the two workpiece surfaces are heated and fused together. It can be widely used in the spot and strip welding of SCR chip lead, fast fuse melt seat, electrical lead terminal, Li ion, Ni MH, Ni Cd battery electrode lug, etc.

1. Ultrasonic metal welding machine is a new equipment which uses the friction principle of ultrasonic high-frequency vibration to transfer the energy of ultrasonic vibration into friction energy to the metal surface to be welded. Under the condition of heat generated by friction and pressure exerted on it, the metal structure molecules are fully activated to form the fusion between molecular layers.

2. Functional features:

Microcomputer control, electronic tuning frequency, LCD display, continuous adjustable power, simple operation, stable and reliable work; solid welding, good consistency, weldment with solid welding surface, high strength, beautiful, environmental protection and other characteristics. Easy to operate, built-in electronic protection circuit, safe to use, used for metal welding of the same kind, can implement single or multi-point welding for non-ferrous metals; widely used in battery and hardware industry.

Type | Power(W) | Frequency (KHz) |

ARS-JSHJ-800W35 | 800W | 35KHz |

ARS-JSHJ-800W40 | 800W | 40KHz |

ARS-JSHJ-1000W15 | 1000W | 15KHz |

ARS-SLHJ-1000W20 | 1000W | 20KHz |

ARS-SLHJ-1000W35 | 1000W | 35KHz |

ARS-SLHJ-1000W40 | 1000W | 40KHZ |

ARS-JSHJ-2000W20 | 2000W | 20KHZ |

ARS-JSHJ-2000W15 | 2000W | 15KHZ |

ARS-JSHJ-3200W15 | 3200W | 15KHZ |

ARS-JSHJ-4200W15 | 4200W | 15KHZ |

![]()

2000W 20KHZ Ultrasonic Metal Welding Equipment For Welding Auto Parts

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian