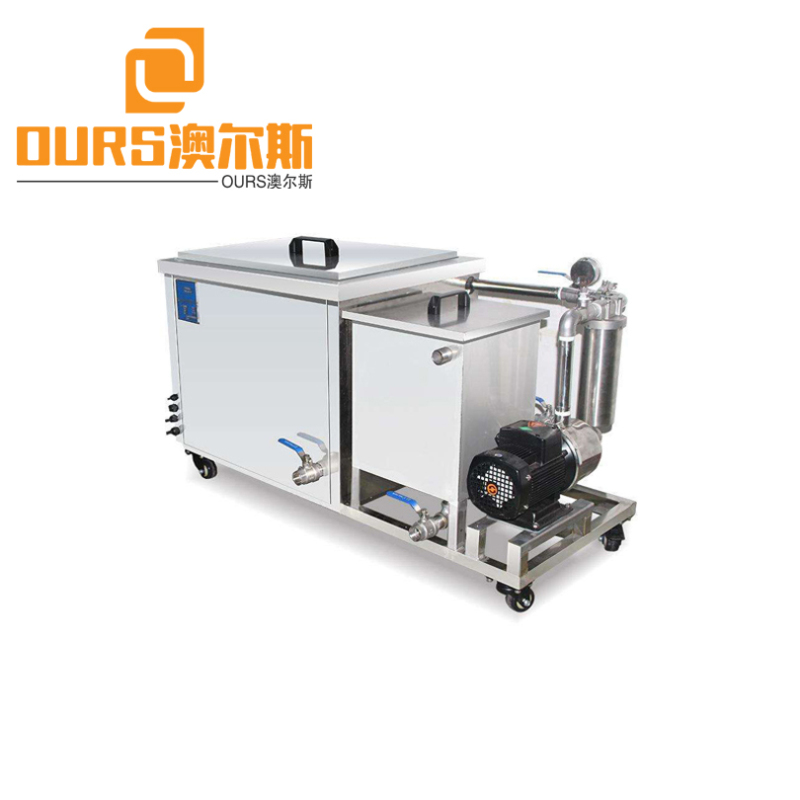

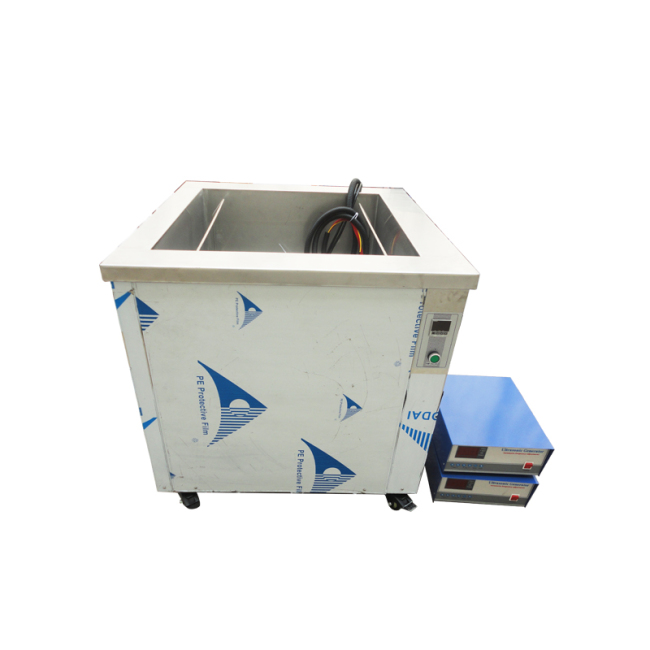

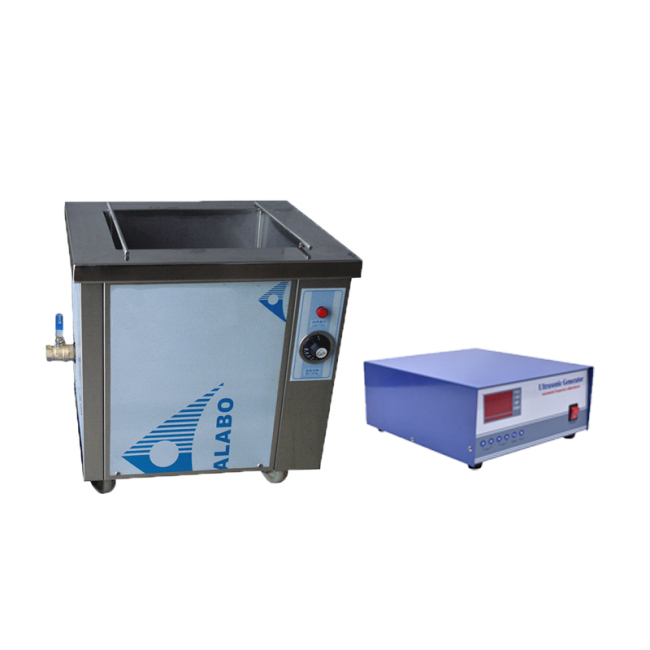

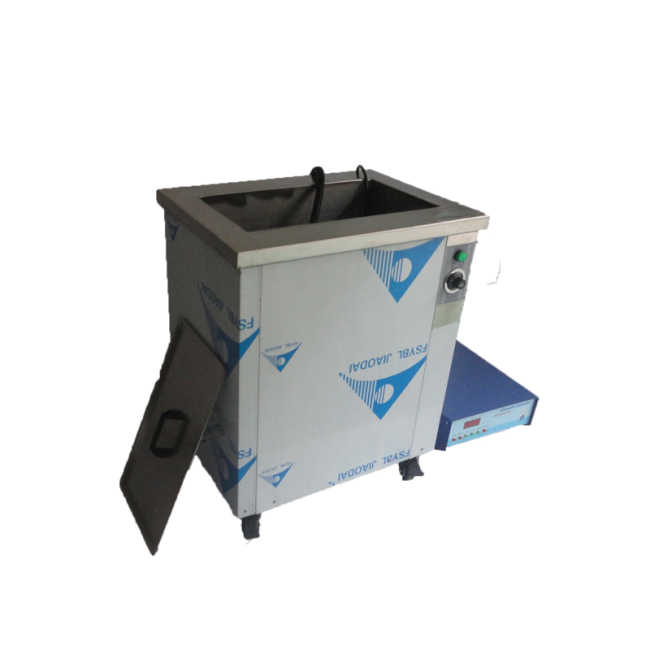

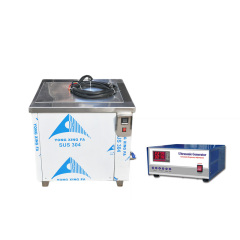

2000Watt 28KHZ Heated Ultrasonic Cleaner With Filter For Cleaning Automotive Parts

1-4 Set

$2,200.00

≥ 5 Set

$2,150.00

- Item No.202107245749bMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

2000Watt 28KHZ Heated Ultrasonic Cleaner With Filter For Cleaning Automotive Parts

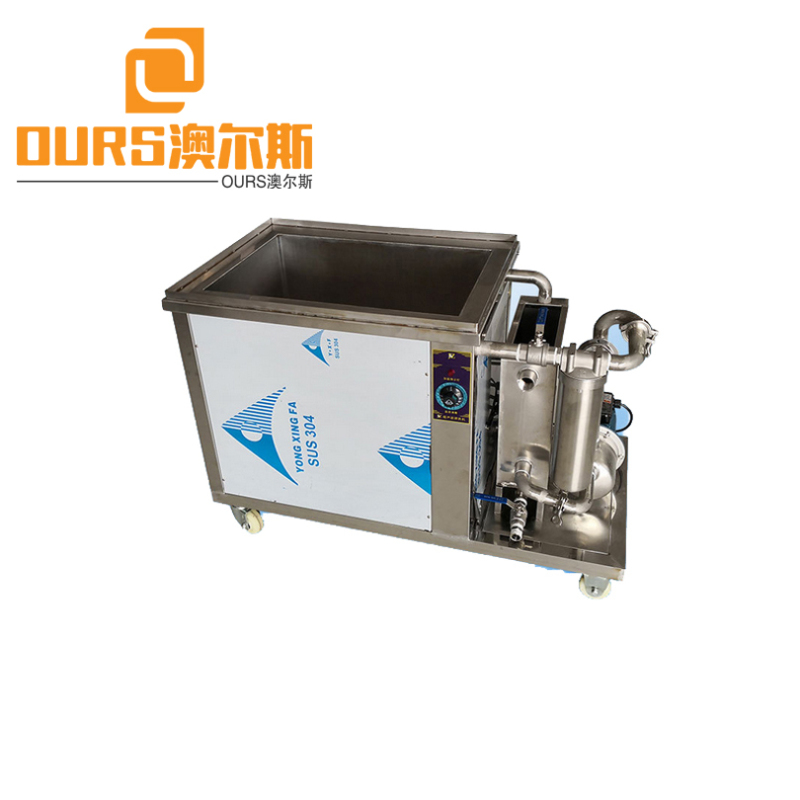

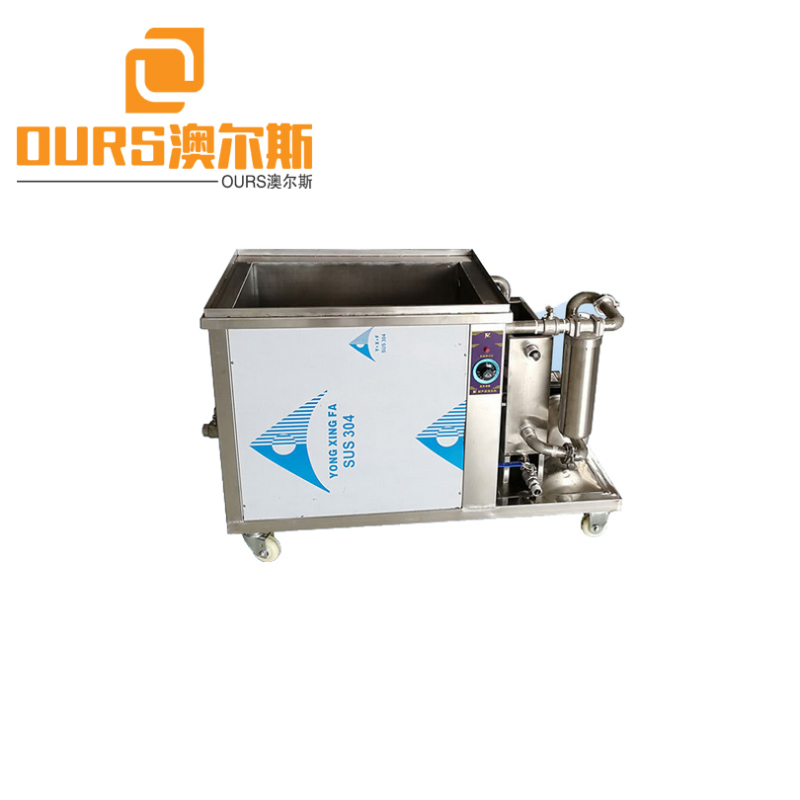

Ultrasonic output frequency according to different working conditions to fine-tune the ultrasound sweep line, to improve the cleaning efficiency. Optional additional features: ultrasonic output power continuously adjustable, you can display the range 10 - 100%; digital The ultrasonic generator using IGBT module, microcontroller technology, more stable working state, the output power is more powerful.

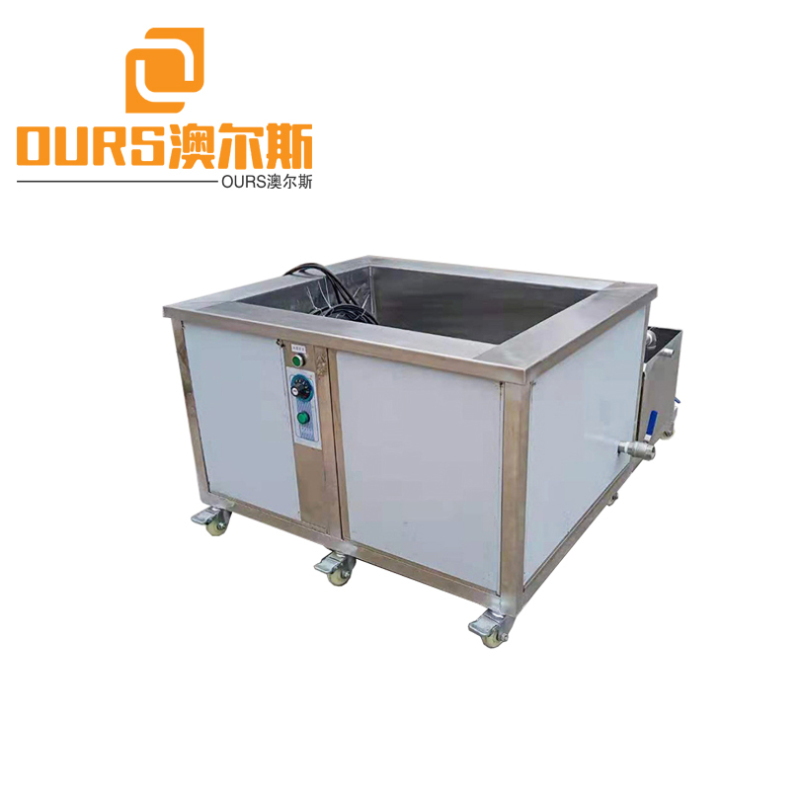

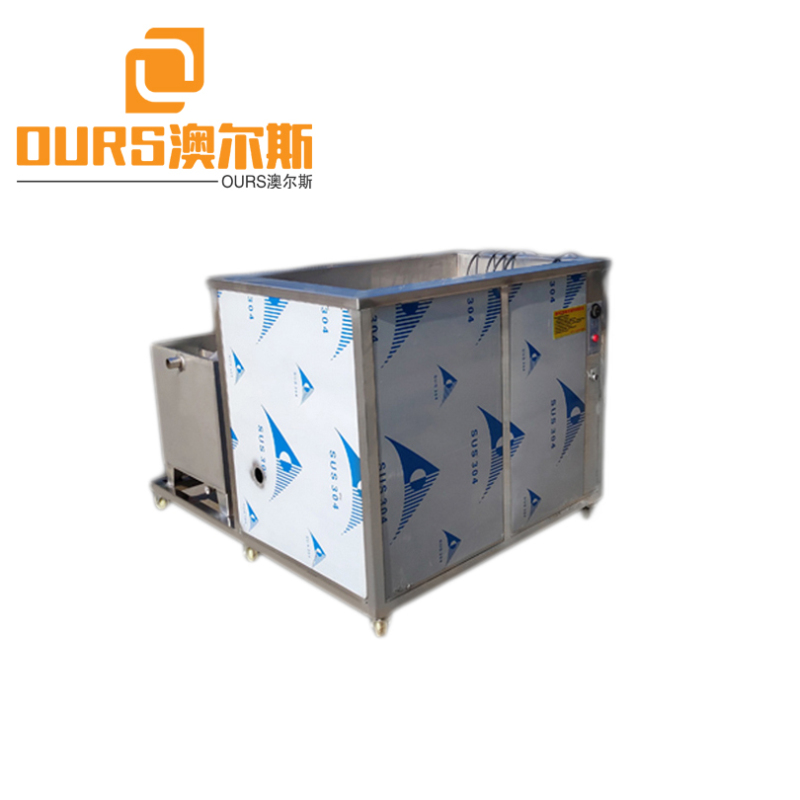

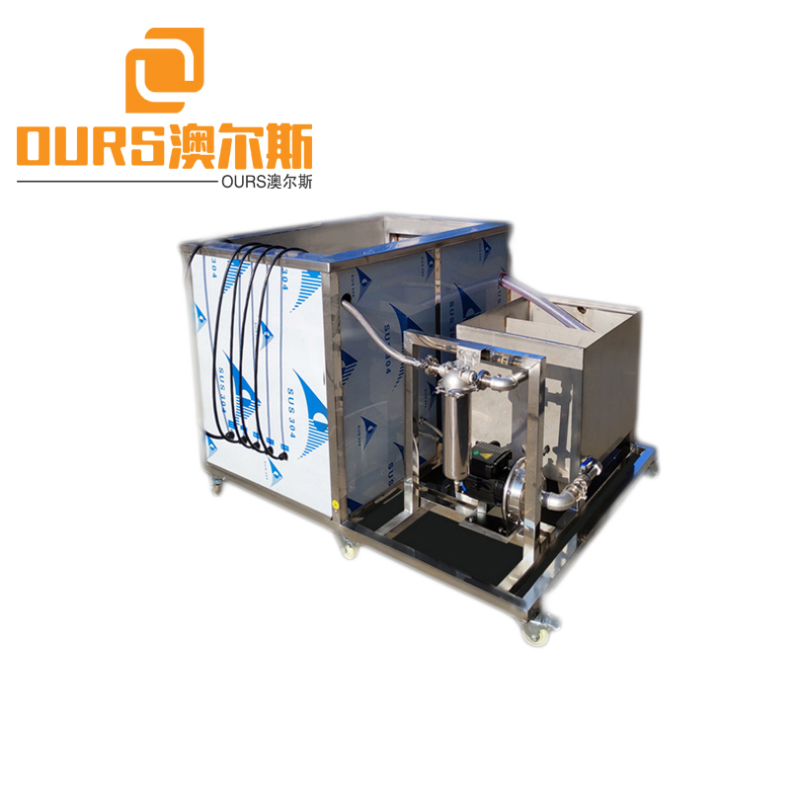

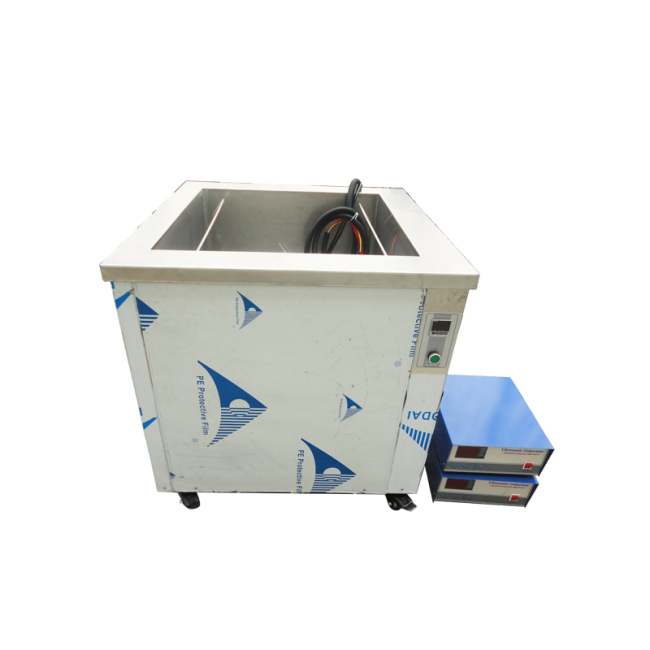

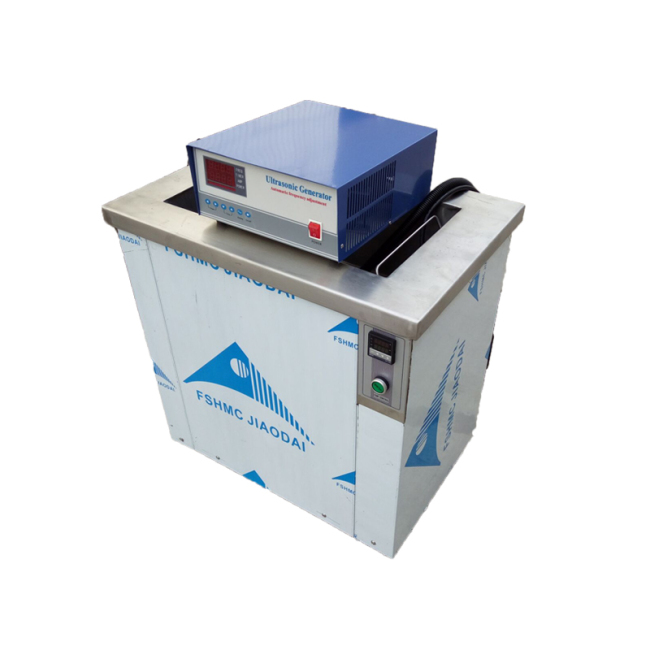

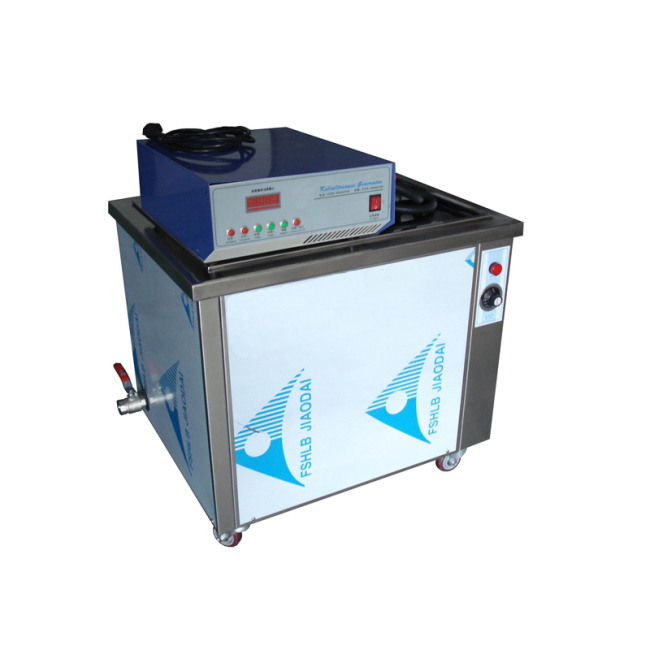

Ultrasonic single tank Product Features:

imported stainless steel plate and components, stainless steel structure, beautiful appearance and durable.

cleaning tank with heating and temperature control devices, temperature control range 30 ~ 110 ℃. .

imported high quality transducer, strong ultrasonic power output.

cleaning tank and generator uses a split-body design, easy to use.

The generator using the new circuit, power adjustable.

ultrasonic vibration, respectively, bottom of vibration and both side vibration, suitable for different cleaning requirements.

ultrasonic cleaning tank, in addition to standard sizes according to customer requirements.

Multi tank ultrasonic cleaning machine using city water, pure water, alkaline or weak acidic, aqueous solvent for cleaning agent, multi and spraying, jet, hot dipping, bubble and cleaning method combined with suitable drying method, semi automatic ultrasonic cleaning production line. Especially suitable for small quantities of electronic circuit boards, electronic parts, clock parts, metal stamping parts, metal parts, jewelry, jewelry, glasses, glass, semiconductor wafers, such as cleaning. With unique technology, strong targeted, simple structure, easy to use and so on, and the equipment cost is low, the investment is little, and can meet the special cleaning requirements of different products.

Ultrasound is a mechanical wave with a higher vibration frequency than sound waves. It is generated by the vibration of the transducer wafer under the excitation of voltage. It has high frequency, short wavelength, small diffraction phenomenon, especially good directivity, which can be directed into rays. Dissemination and other characteristics. Ultrasound has a great ability to penetrate liquids and solids, especially in solids that are opaque to sunlight, where it can penetrate to a depth of tens of meters. When the ultrasonic wave hits the impurity or the interface, it will produce a significant reflection to form an echo, and it can produce a Doppler effect when it hits a moving object. Therefore, ultrasonic testing is widely used in industry, national defense, biomedicine, etc.

What is the working principle of the multi-slot ultrasonic cleaning machine? The following is an introduction to the main links and steps of its work, the principle and knowledge of how the multi-tank ultrasonic cleaning machine works. The principle of the ultrasonic cleaning machine is mainly to convert the sound energy of the power ultrasonic frequency source into mechanical vibration through the transducer, and radiate the cleaning liquid in the tank to ultrasonic waves through the cleaning tank wall. Due to the radiated ultrasonic waves, the microbubbles in the liquid in the tank can maintain vibration under the action of sound waves.

When the sound pressure or sound intensity reaches a certain level, the bubble will expand rapidly and then suddenly close. During this process, the shock wave is generated at the moment when the bubble is closed, causing a pressure of 1012-1013pa and local temperature adjustment around the bubble. The huge pressure generated by this ultrasonic cavitation can destroy insoluble dirt and make them differentiate in the solution. The direct and repeated impact of steam-type cavitation on dirt.

On the one hand, it destroys the adsorption of the dirt and the surface of the cleaning part, and on the other hand, it can cause the fatigue damage of the dirt layer and be dismissed. The vibration of the gas bubble scrubs the solid surface. Once the dirt layer is cracked, the bubbles are immediately " The “drilling” vibration causes the dirt layer to fall off. Due to cavitation, the two liquids are rapidly dispersed and emulsified at the interface. When the solid particles are wrapped in oil and adhere to the surface of the cleaning part, the oil is emulsified and the solid particles fall off by themselves. When it propagates in the cleaning liquid, it will produce positive and negative alternating sound pressure, forming a jet, which impacts the cleaning part. At the same time, due to the nonlinear effect, it will produce acoustic and micro-acoustic flow. Ultrasonic cavitation will produce high-speed at the solid-liquid interface. Microjets, all of these effects, can destroy dirt, remove or weaken the boundary dirt layer, increase stirring and diffusion, accelerate the dissolution of soluble dirt, and strengthen the cleaning effect of chemical cleaning agents. It can be seen that any place where the liquid can be immersed and the sound field has a cleaning effect, and its characteristics are suitable for cleaning parts with very complicated surface shapes. Especially after adopting this technology, the amount of chemical solvents can be reduced, thereby greatly reducing environmental pollution.

2000Watt 28KHZ Heated Ultrasonic Cleaner With Filter For Cleaning Automotive Parts

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian