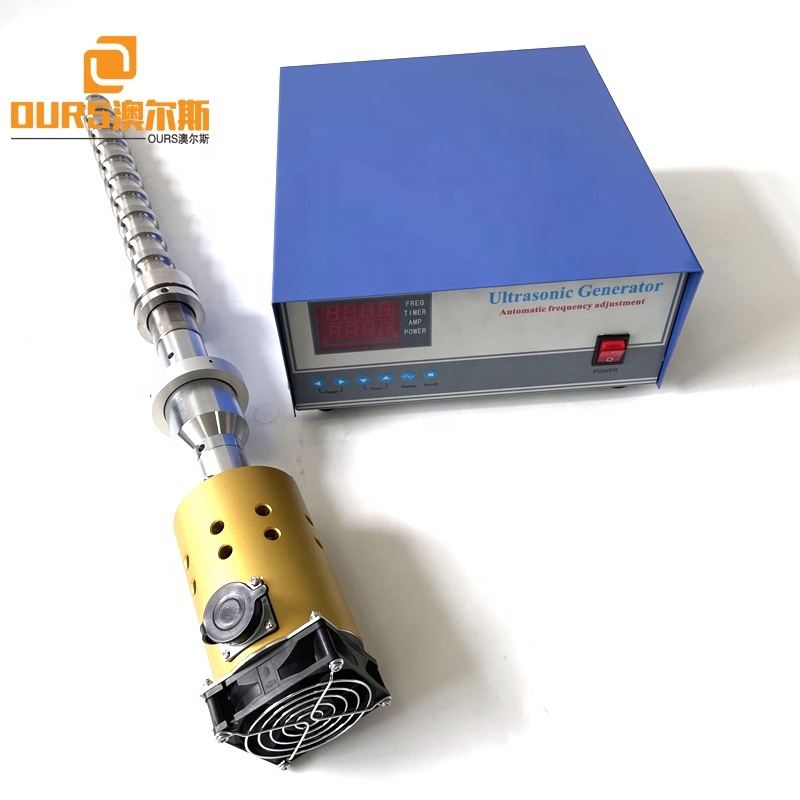

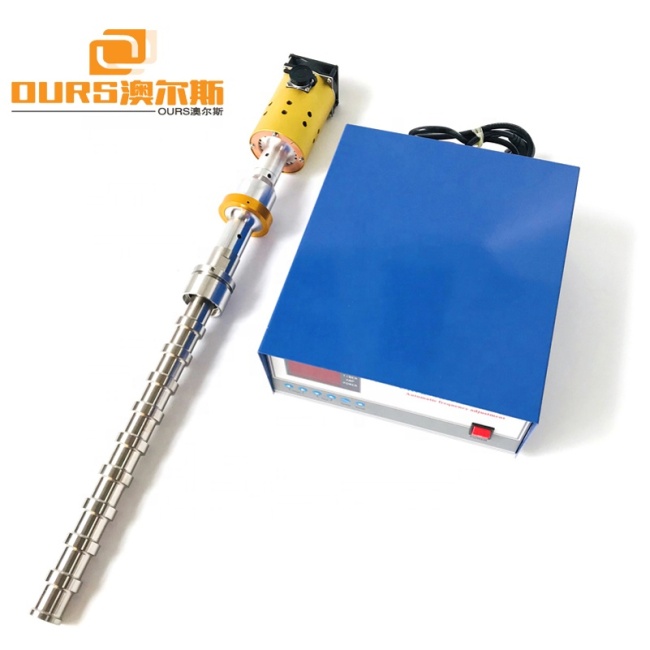

200W-2000W Titanium Alloy Ultrasonic Vibrator Dispersion Extraction Biological Cell Break

1-9 Set

$2,980.00

10 -29 Set

$2,700.00

≥ 30 Set

$2,500.00

- Item No.202105184d365MOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

The principle of ultrasonic vibrating rod: Ultrasonic technology is mainly used as a physical means and tool to form a series of conditions close to extreme critical when generating a chemical reaction. This energy can not only stimulate the chemical reaction, speed up the chemical reaction speed, efficiency, or even It can also change the nature of certain chemical reactions, etc., so that the original chemical composition produces some unexpected effects and functions. This is called sonochemistry. Almost all chemical reactions can use sonochemistry as a physical aid, such as extraction and separation, synthesis, biodiesel production, treatment of microorganisms, degradation of toxic organic pollutants, biodegradation treatment, biological cell crushing, dispersion and coagulation, etc. . Therefore, the ultrasonic vibrating rod can not only be used to clean the object and peel the dirt off the surface of the object, but also contribute to the further success of scientific research.

The working principle and function of ultrasonic vibration rod:

The following describes the three functions of the ultrasonic vibrator.

Ultrasonic Dispersion: The process of dispersing and deagglomerating the particulate matter in the liquid by using the liquid as the medium and the "cavitation" effect of the ultrasonic wave in the liquid. Ultrasonic dispersion can be divided into emulsion dispersion, that is, dispersion of liquid and liquid; and dispersion of suspension, that is, dispersion of solid and liquid. Its function has been effectively practiced and applied in many fields. Among them, the application of ultrasound to the dispersion of suspensions, such as the dispersion of titanium oxide in paints and plastics industries in water or solvents, the dispersion of dyes in molten paraffin; the dispersion of drug particles in the pharmaceutical industry; and the powder milk in the food industry Dispersion of agents, etc.

Ultrasonic extraction: Ultrasonic extraction separation is mainly based on a scientific and rational design of a new process of extraction based on the effective state of the substance and the existence, polarity, solubility, etc. of the effective ingredient group, so that the solvent is quickly spread throughout Go to all corners of the surface of the solid material, dissolve the organic components contained in the material as completely as possible in the solvent to obtain a multi-component mixed extract, and then use appropriate separation methods to separate the chemical components in the extract Then, it is refined and purified. After such a complete process, the final required monomer chemical composition can be obtained.

Ultrasonic emulsification: Ultrasonic emulsification means that under the action of ultrasonic energy, two (or more than two) immiscible liquids are mixed to form a dispersed system, one of which is evenly distributed in the other and then forms a milky liquid crafting process. The physical mechanism of crushing insoluble solids (or liquids) is the cavitation of ultrasonic waves. Ultrasonic cavitation effect means that under the action of ultrasonic waves, a large number of bubbles will be generated in the liquid. The small bubbles will gradually increase with ultrasonic vibration, and then burst and split suddenly. Tens of thousands of small bubbles will increase and repeat. Burst, when collapsed rapidly, high temperature and high pressure will be generated in the bubble, and due to the high speed of the liquid around the bubble rushing into the bubble, a strong local oscillation wave is generated in the liquid near the bubble, which also forms a local high temperature and high pressure, resulting Ultrasonic crushing and emulsification.

US equipment | Frequency (KHz) | Ultrasound Output(W) | Total Length (mm) | Diameter (mm) | Static Capacity (pF±10%) |

ARS-HLCSB-1000

| 15-28 | 1000

| 500

| Φ50-55

| 68000

|

ARS-HLCSB-1500

| 15-28

| 1500

| 850 | Φ50-55

| 68000

|

ARS-HLCSB-2000

| 15-28

| 2000

| 1100 | Φ50-55

| 132000

|

Widely used in the traditional ultrasonic cleaning, biochemistry, food, chemical, pharmaceutical and other industries. Biochemistry, ultrasound rods canbe applied to large-scale emulsification, separation, homogenization, extraction, catalytic reaction, increase productivity; the homogeneous uniform mixing in the food industry, ultrasound rods use played a role can not be underestimated; in chemical industry, ultrasound stick for pipes, tanks, acauldron class cleaning. Biodiesel abandoned oil and palm oil refining process, the catalytic effect of ultrasound astonishing efficiency ten times, and andamazing promotion prospects in the petrochemical industry.

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian