20KHZ/25KHZ/28KHZ 5000W High Power Ultrasonic Cleaner Immersion Shock Plate For Cleaning Electroplated Hardware

1-9 Set

$2,100.00

≥ 10 Set

$1,950.00

- Item No.202011040708dMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

20KHZ/25KHZ/28KHZ 5000W High Power Ultrasonic Cleaner Immersion Shock Plate For Cleaning Electroplated Hardware

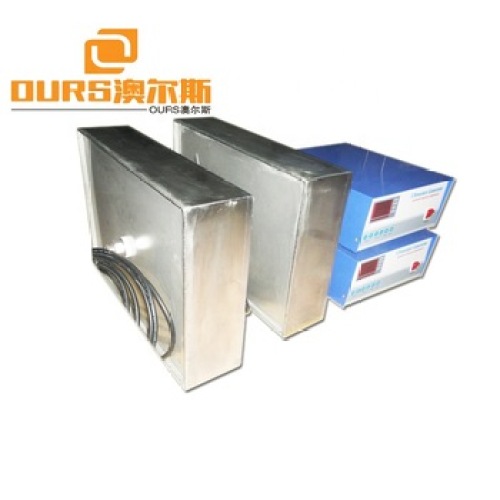

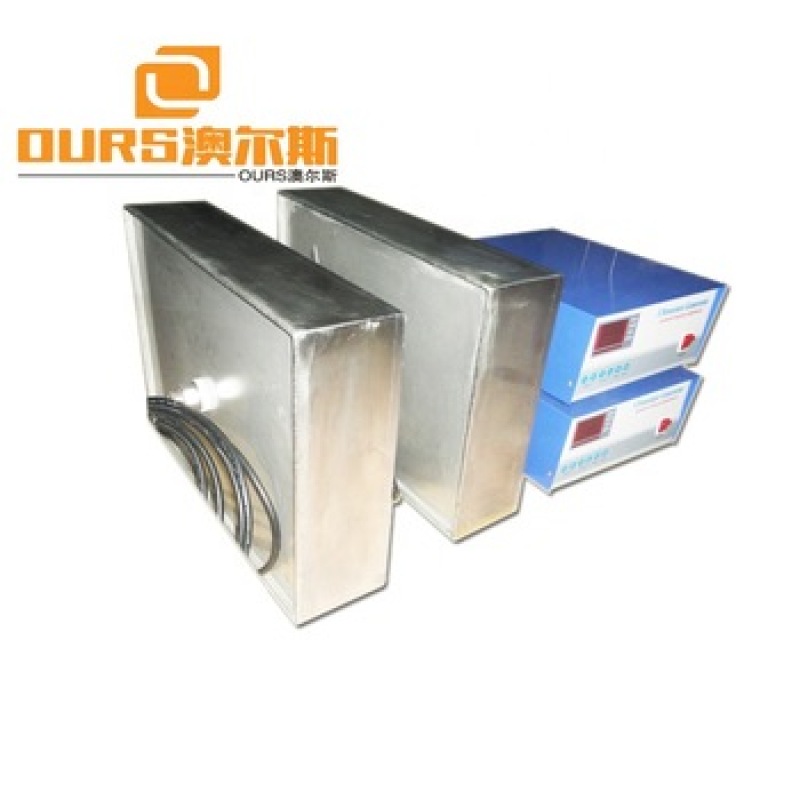

Ultrasonic Immersible Transducer Pack also called the inputting type ultrasonic vibration plates, this product is suitable for cleaning electroplating parts before cleaning, horologe parts, hardware machinery parts, polyester filtering cores, semiconductor wafer, tools, lens, frames, jewellery, glass, utensils and other industries, wide application.

immersible ultrasonic transducers This series of products is suitable to cleaning work pieces of various industries;such as plating components cleaning before plating,electronic,hardware machinery parts,clock and watch parts,semiconductor sillcon chips,glass vessels,bijouterie,spectacle frame, etc.

Immersion type ultrasonic vibration plate, this product is suitable for various industries such as cleaning before washing electroplated parts, clock parts, hardware machinery parts, polyester filter elements, semiconductor silicon wafers, tools, lenses, glasses frames, jewelry, jewelry, glass, utensils and other industries Wider.

Advantages of ultrasonic vibration plate:

1. The ultrasonic vibration plate is composed of a vibration plate and an ultrasonic generator. When the standard model ultrasonic cleaning machine is not suitable for a specific working environment, in addition to special specifications can be customized. It is also possible to use an input type shock plate device and convert it into an ultrasonic cleaning machine, which can save equipment costs and achieve cleaning results.

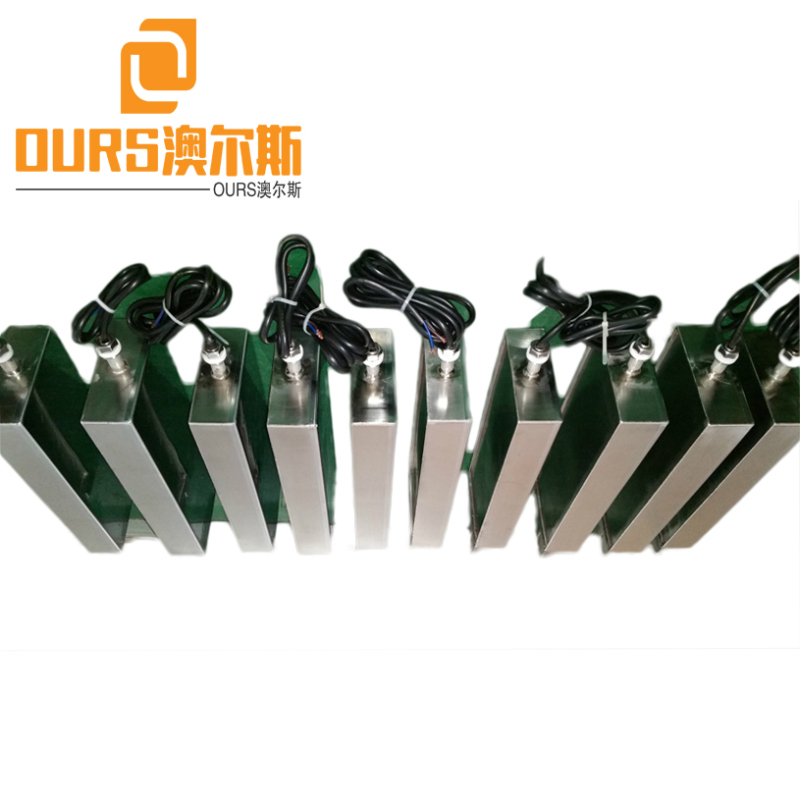

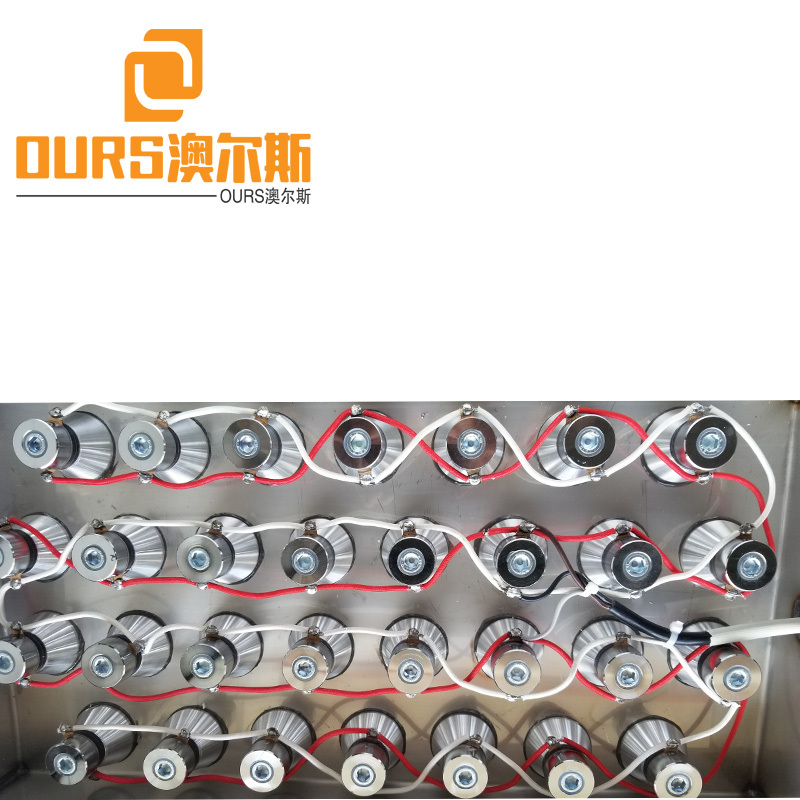

2. The shock plate adopts all stainless steel structure for alkali and acid resistance, and the surface of the shock plate is plated with hard chrome. The ultrasonic transducer uses high-quality and high-performance products with high electro-acoustic conversion efficiency.

3. The split structure is adopted, and the high frequency cable with socket is connected between the shock plate and the ultrasonic generator, which is convenient to use and maintain.

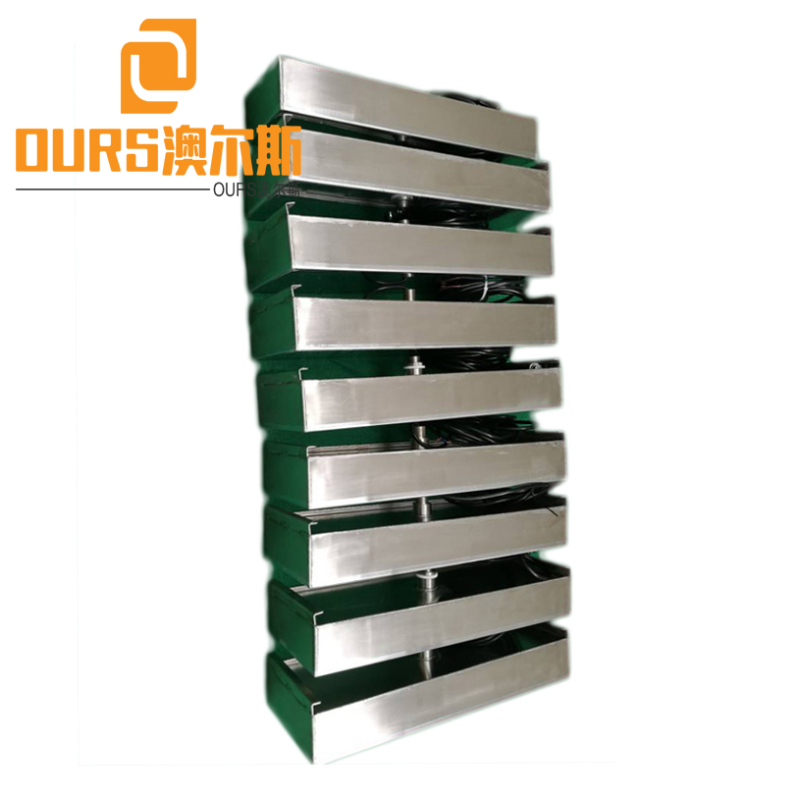

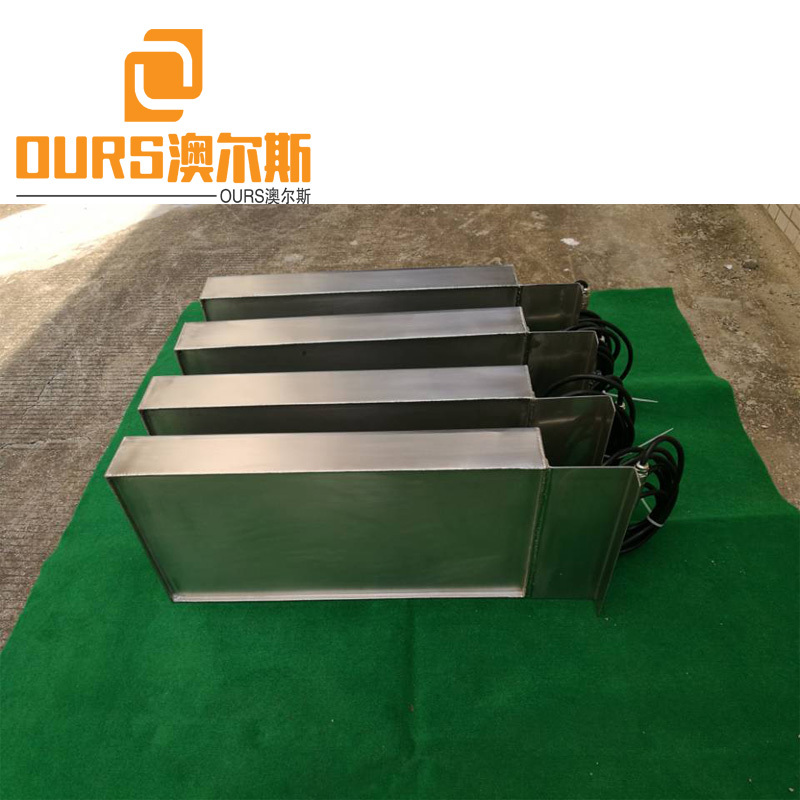

4. The installation arrangement is flexible, and the ultrasonic radiation surface can be arranged on the bottom surface, side surface or top surface of the cleaning tank as required.

5. Ultrasonic vibration plates can be customized according to customer requirements. Ultrasonic vibration plates are suitable for cleaning before cleaning electroplated parts, clock parts, hardware machinery parts, polyester filter cores, semiconductor silicon wafers, tools, lenses, glasses frames, jewelry, jewelry, glass, utensils. And other industries, widely used.

Ultrasonic shock board input device consists of two shock plate and the ultrasonic generator parts. When the standard model of the ultrasonic cleaner does not apply to a particular work environment, in addition to custom-made special specifications, but also can be put into type shock plate device. The existing equipment, if there ordinary cleaning tank, you can add into the shock plate device, converted into ultrasonic cleaning machine. 316L stainless steel, acid and alkali resistant, beautiful and durable. Using split structure between the shock plate and the ultrasonic generator frequency using socket connection with the use and maintenance are easy.

Installation layout flexibility, according to the needs of ultrasonic cleaning tank can be arranged in radiating the bottom, side or top.

1, all stainless steel, acid, attractive and durable, with a strong acid and alkali titanium sheet, reinforced encryption welding;

2, thick stainless steel welding, sealing performance;

3, the U.S. sub-high-Q shock, ultrasonic power strong;

4, the ultrasonic generator and shock plate with high-frequency

28 KHz - suit for heavy oil dirt cover cleaning object. Do not use on thin delicate materials like glass, brass, aluminum...

40 KHz - Standard frequency which can be compatible on a wide range of material and for removing a lot of contaminants.

The input type ultrasonic shock plate device consists of shock plate and ultrasonic generator. When the trough type ultrasonic cleaner is not suitable for a specific working environment, the input type shock plate device can be used. For example, in the existing equipment, there is a common cleaning tank, you can add shock plate device, refitted into an ultrasonic cleaning machine. All stainless steel structure, acid and alkali resistance, beautiful and durable. The split structure is adopted, and the high frequency connection with socket between the shock plate and the ultrasonic generator is adopted, which is convenient to use and maintain. The installation and layout are flexible, and can be made into three types: bottom shock type, side shock type and top shock type according to different needs to meet various cleaning requirements.

Scope of application: cleaning electroplated parts before plating, clocks and watches, hardware and machinery parts, polyester filter core, semiconductor silicon, tools, lenses, spectacle frames, jewelry, glassware

Applied areas of electroplating industry: grease, polishing wax and dirt removal.

Pharmaceutical industry: Chinese medicine extraction, bottle cleaning. Optical industry: lens, prism, lens, frame, liquid crystal glass, etc. before and after coating or assembly cleaning.

Machinery industry: oil pump nozzle, engine parts, steam and friction parts, compressor parts, sewing machine parts, metal stamping parts cleaning.

Hardware industry: hardware tools, garden tools, medical equipment cleaning. Other industries: ceramics, tableware, lamps, accessories, crystal, metal pipe cleaning. This product is made of imported high quality stainless steel. The radiant surface of vibration plate has been specially treated, and its service life has been prolonged by more than 50%. It is easy to install, and can be installed at the bottom of the groove to radiate the ultrasonic wave upward, or on the side of the groove or on the liquid surface to emit the ultrasonic wave downward. The specific installation method should be determined according to the shape of the workpiece and the cleaning requirements. The ultrasonic power and the size of the vibration box should be determined according to the volume of the cleaning tank. The general power density should be between 8 and 15KW/m.

Machinery and equipment cleaning advantages:

Good cleaning effect, high cleanliness and uniform cleanliness of all workpieces

_Cleaning speed is fast and production efficiency is improved

_No need to touch the cleaning fluid by hand, and clean the deep holes, slits and hidden parts safely and reliably.

_No damage to workpiece surface

_Save solvents, heat, workplaces and manpower, etc.

Deep cleaning ultrasonic immersible transducers give you the ability to add the ultrasonic advantage to your existing cleaning application. We bond and wire the immersible transducer inside a durable stainless steel container, and seal it with a stainless steel lid. This gives you the ability to "drop-in" transducers to an existing tank or application.

Heavy duty 316L stainless steel- to insure long life and performance

Installation hardware included- to insure ease of installation

Custom sizes available- contact our knowledgeable sales engineers for assistance

OURS manufactures engineered equipment that fulfills the broad spectrum of performance requirements dictated by the various cleaning applications. The varied frequency requirements are met by OURS’s "Multi-Frequency" which insures constantly uniform and thorough cleaning..

Type Description

A.Mounting to tank wall with threaded duct nipple and fastening bracket. Cable through the tank wall.

B.Mounting to tank wall with threaded duct nipple and fixing nipple. Cable through the tank wall.

C.Mounting to tank wall with hanging hooks. Rigid stainless steel tube for cable over the tank top.

D.Mounting to tank wall with hanging hooks. Flexible metal armoured 1 m hose for cable over the tank top.

E.Mounting to tank bottom. Rigid stainless steel tube for cable through the tank wall.

F.Mounting to tank bottom. Rigid stainless steel tube for cable over the tank top.

G.Mounting to tank bottom. Flexible metal armoured 0,5 m hose for cable through the tank wall.

H. Mounting to tank bottom. Flexible metal armoured 1,5 m hose for cable over the tank top.

X.Non-standard mounting

Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

ARS-ZBH300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

ARS-ZBH600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

ARS-ZBH1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

ARS-ZBH1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

ARS-ZBH1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

ARS-ZBH1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

ARS-ZBH2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

ARS-ZBH2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

ARS-ZBH3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

ARS-ZBH5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

Above are single frequency ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

20KHZ/25KHZ/28KHZ 5000W High Power Ultrasonic Cleaner Immersion Shock Plate For Cleaning Electroplated Hardware

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian