20KHZ-40KHZ 300W Immersible Ultrasonic Cleaning For Existing Tank

1-9 Set

$480.00

≥ 10 Set

$450.00

- Item No.20201126a2284MOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

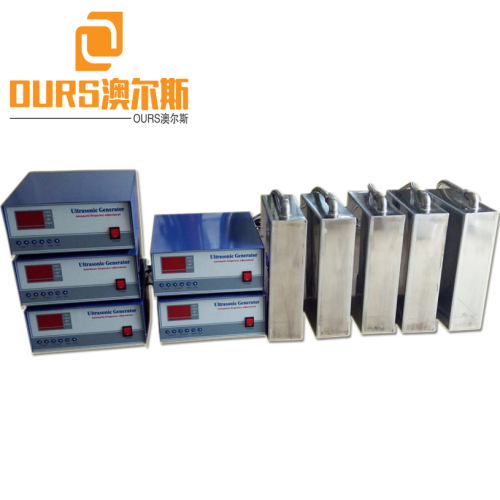

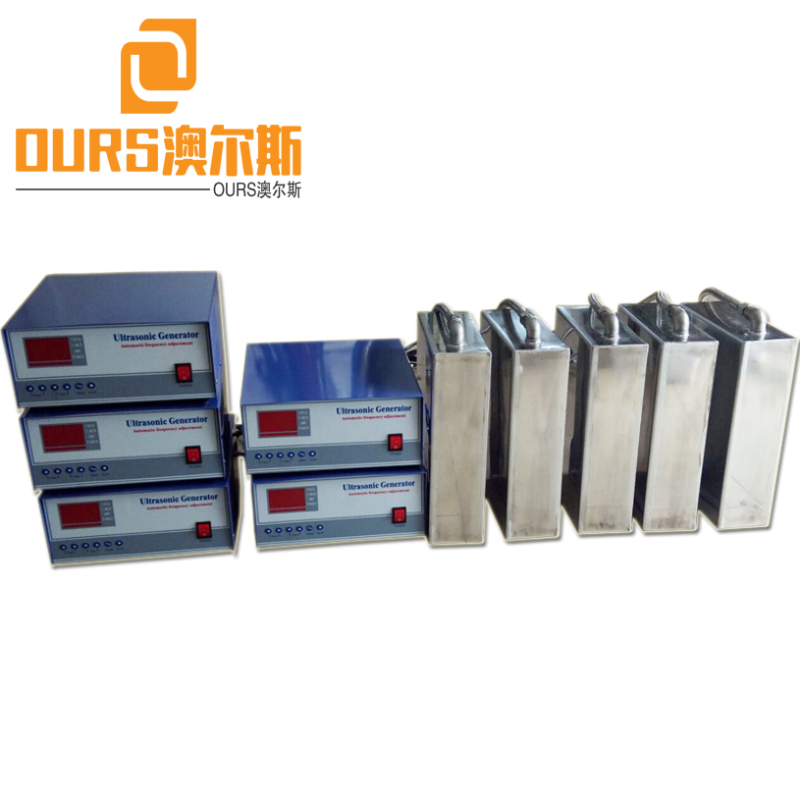

20KHZ-40KHZ 300W Immersible Ultrasonic Cleaning For Existing Tank

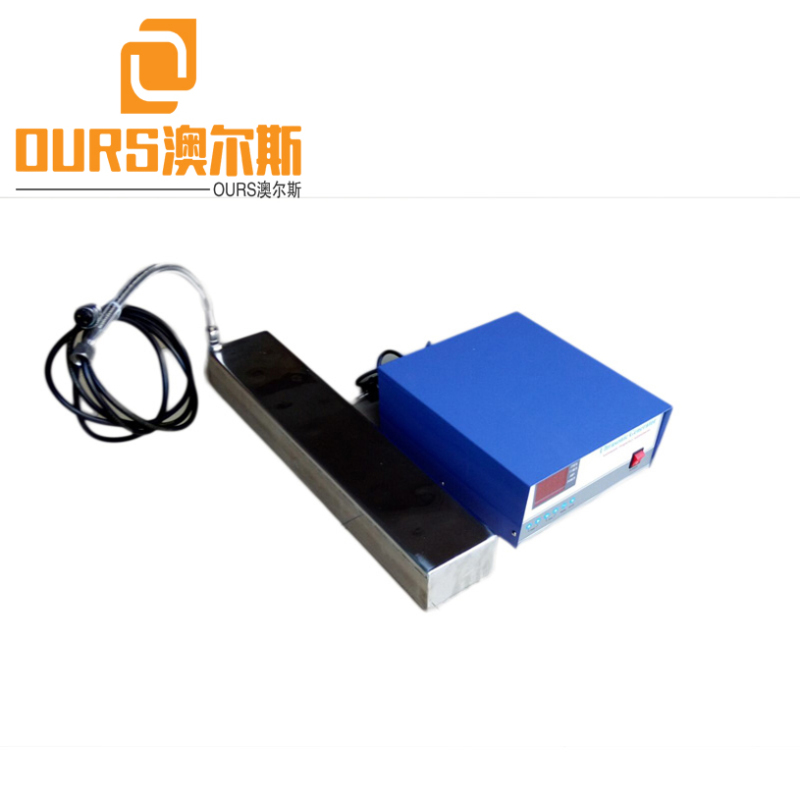

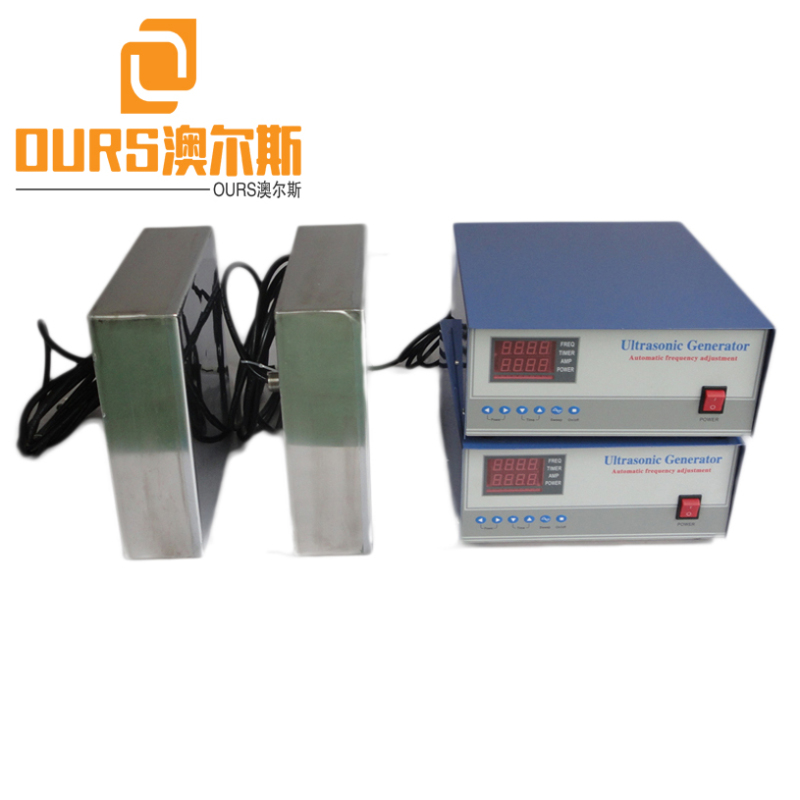

300W Underwater Industrial Ultrasonic Cleaners Immersion Submersible Ultrasonic Transducers Pack

Ultrasonic Immersible Transducer Pack also called the inputting type ultrasonic vibration plates, this product is suitable for cleaning electroplating parts before cleaning, horologe parts, hardware machinery parts, polyester filtering cores, semiconductor wafer, tools, lens, frames, jewellery, glass, utensils and other industries, wide application.

1. Immersible ultrasonic transducer unit can be installed in the tank by three ways: side, top and bottom. 1.The ultrasonic cleaning device is composed of the immersible ultrasonic transducer and generator. If ultrasonic cleaning machine of the standard model cannot be applied to a specific working environment, you can also make immersible ultrasonic transducer pack according to customizing special specifications. The working positions can be installed to fluid tank top side, bottom side or both side to achieve different cleaning effects..

2. It is of an all stainless steel structure, acid- and alkali-resistant, beautiful and durable. Strong acid- and strong alkali-resistant titanium plate material is used to reinforce and tighten welding..

3.It is welded with thick 316L stainless steel, which has good sealing performance..

4.The ultrasonic generator and immersible transducer are connected with separated high frequency wires, which is convenient for repair and maintenance..

5. It can work continuously for 24 hours, which is suitable for mass production.

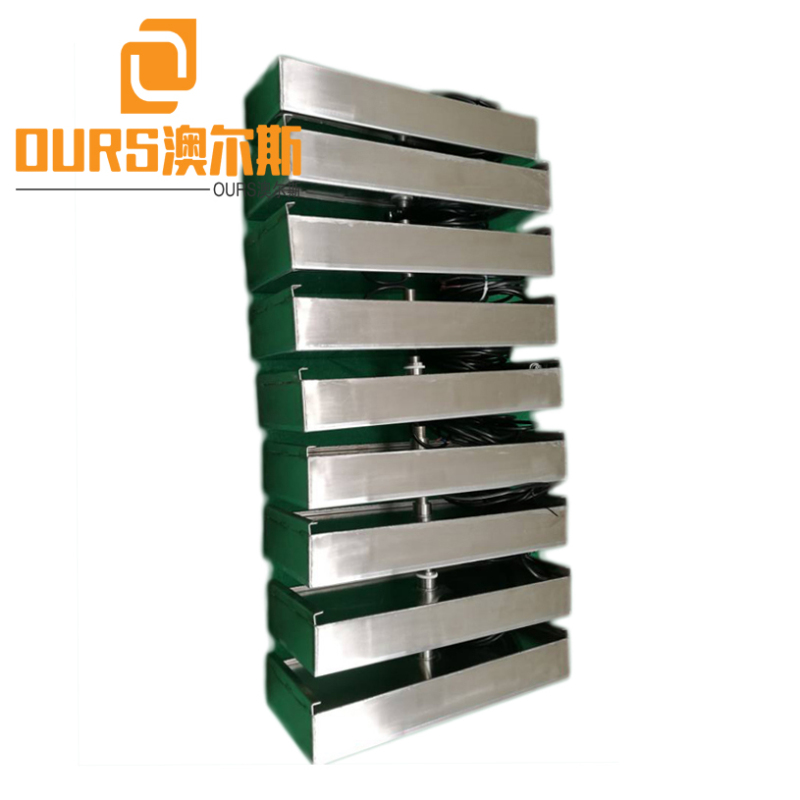

The vibration plate is divided into: input ultrasonic vibration plate, flange type vibration plate and detachable ultrasonic vibration plate. The split structure is adopted, and the high-frequency wire with socket is used for connection between the vibration plate and the ultrasonic generator, which is convenient for use and maintenance.

Features of ultrasonic vibration plate:

The ultrasonic vibration plate is driven by the international advanced digital pulse method. Compared with the traditional self-excited control technology, it has obtained many experts with the advantages of small size, light weight, strong power, stable and reliable work, continuously adjustable power, and flexible control. Recognition. The automatic frequency tracking of the ultrasonic cleaner ensures that the machine is in the best working condition from beginning to end, and can maximize the potential of the ultrasonic transducer. It also has complete protection functions; overcurrent protection, overheat protection, and output short-circuit protection. Real-time digital display, working frequency and ultrasonic output power are more intuitive. It is also equipped with a remote control port, which can be easily applied to a fully automatic production line.

Application scope of ultrasonic vibration plate:

1. Machinery industry: removal of anti-rust grease; cleaning of measuring tools; degreasing and rust removal of mechanical parts; cleaning of engines, carburetors and auto parts; dredging and cleaning of filters and screens, etc. Especially in the railway industry, it is very suitable for the degreasing and decontamination of the air conditioner of the train carriage, and the derusting, degreasing and anti-rusting of the various parts of the train head.

2. Surface treatment industry: degreasing and rust removal before electroplating; cleaning before ion plating; phosphating treatment; removing carbon deposits; removing oxide scale; removing polishing paste; surface activation treatment of metal workpieces, etc.

3. Instrumentation industry: high cleanliness of precision parts, cleaning before assembly, etc.

4. Electronic industry: Removal of rosin and solder spots on printed circuit boards; cleaning of mechanical and electronic parts such as high voltage contacts.

5. Medical industry: cleaning, disinfection, sterilization of medical equipment, cleaning of test utensils, etc.

6. Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

7. Watch and jewelry industry: remove sludge, dust, oxide layer, polishing paste, etc.

8. Chemical and biological industries: cleaning and descaling of laboratory utensils, etc.

9. Optical industry: degreasing, sweating and dust removal of optical devices.

10. Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

11. Petrochemical industry: cleaning and dredging of metal filters, cleaning of chemical containers, exchangers, etc.

12. Others: liquid defoaming (removing dissolved air) in photosensitive material manufacturing, papermaking, and certain food fields.

Type Description

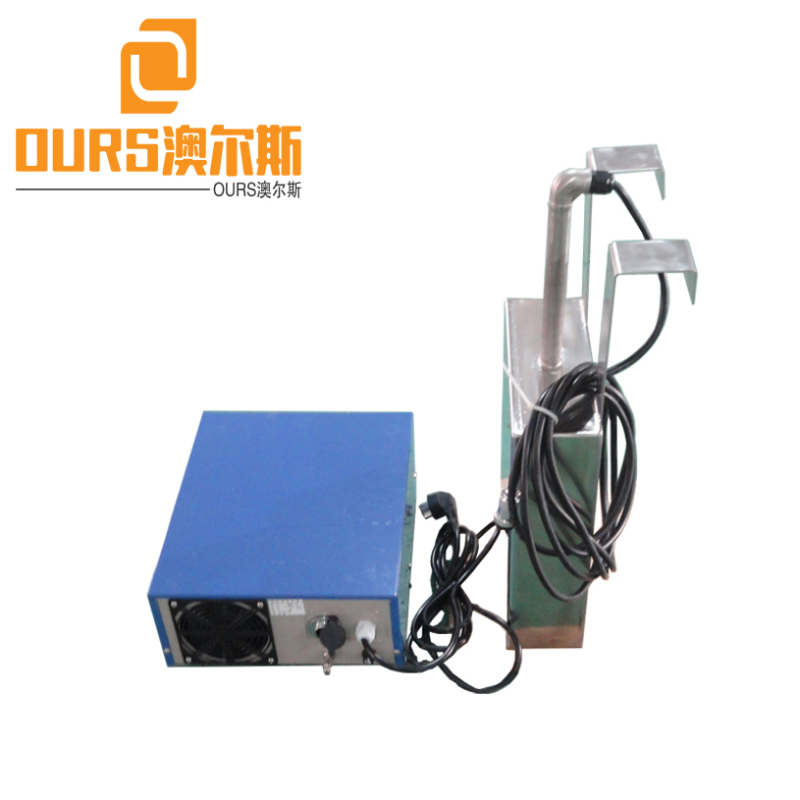

A.Mounting to tank wall with threaded duct nipple and fastening bracket. Cable through the tank wall.

B.Mounting to tank wall with threaded duct nipple and fixing nipple. Cable through the tank wall.

C.Mounting to tank wall with hanging hooks. Rigid stainless steel tube for cable over the tank top.

D.Mounting to tank wall with hanging hooks. Flexible metal armoured 1 m hose for cable over the tank top.

E.Mounting to tank bottom. Rigid stainless steel tube for cable through the tank wall.

F.Mounting to tank bottom. Rigid stainless steel tube for cable over the tank top.

G.Mounting to tank bottom. Flexible metal armoured 0,5 m hose for cable through the tank wall.

H. Mounting to tank bottom. Flexible metal armoured 1,5 m hose for cable over the tank top.

X.Non-standard mounting

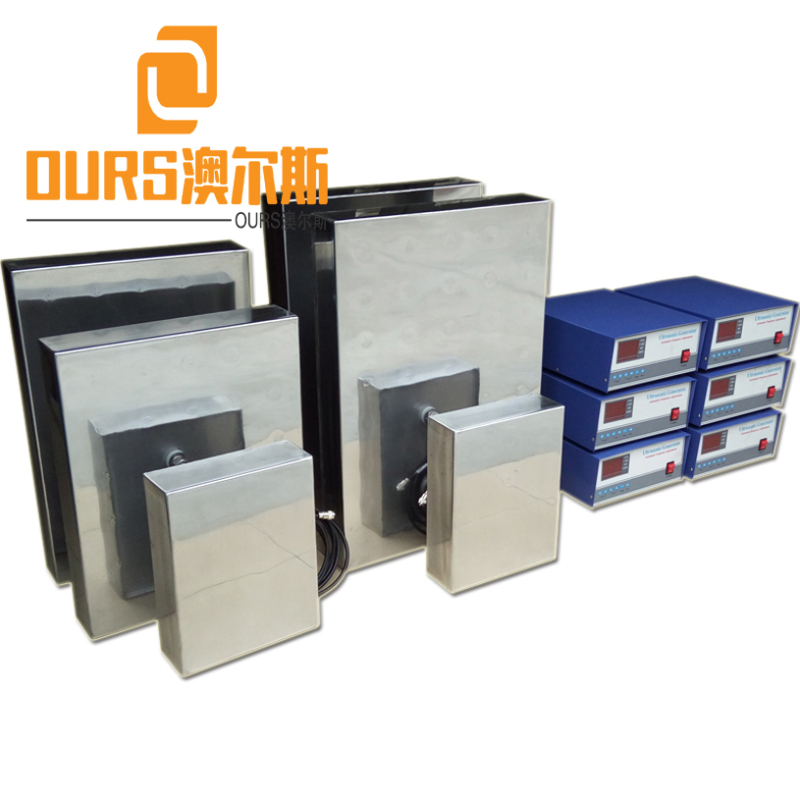

300W Underwater Industrial Ultrasonic Cleaners Immersion Submersible Ultrasonic Transducers Pack

Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

ARS-ZBH300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

ARS-ZBH600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

ARS-ZBH1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

ARS-ZBH1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

ARS-ZBH1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

ARS-ZBH1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

ARS-ZBH2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

ARS-ZBH2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

ARS-ZBH3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

ARS-ZBH5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

Above are single frequency ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

20KHZ-40KHZ 300W Immersible Ultrasonic Cleaning For Existing Tank

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian