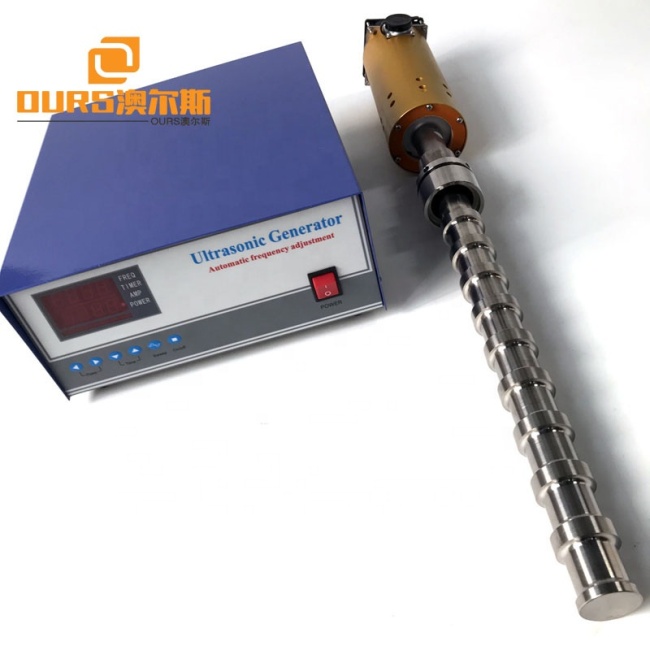

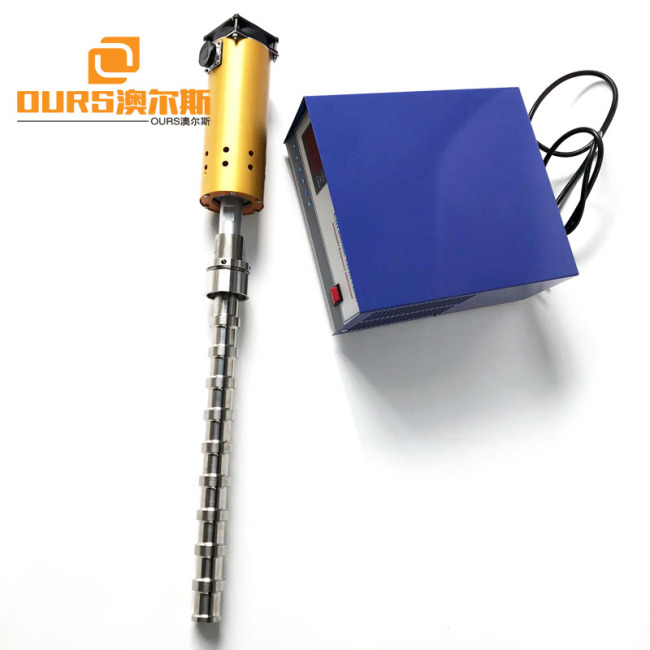

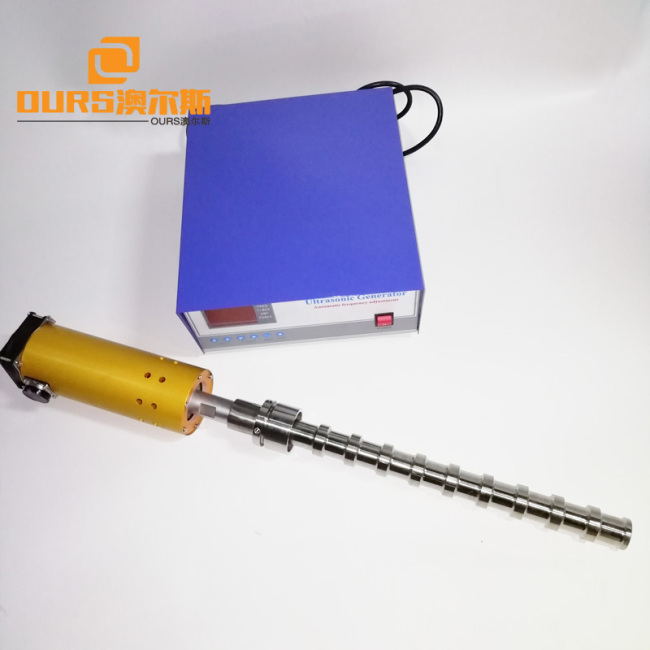

20khz 1500watt Ultrasonic Transducer Homogenizer Used On Clean Bath Extract Vanilla Plant Liquid

1-9 Set

$2,790.00

10 -29 Set

$2,600.00

≥ 30 Set

$2,400.00

- Item No.202107242cbaeMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

OURS Sonics manufactures the most technologically advanced and reliable ultrasonic processors in the industry for applications such as: dispersion of nanoparticles, nanotubes and Graphene; cell lysing and cell disruption; sample prep; ChIP assay; homogenization; extraction; atomization; and more.

Ultrasonic liquid processing is a highly valuable methodology in the laboratory. High intensity (20 kHz range) ultrasonic generation is sufficiently powerful to achieve useful liquid processing in a wide variety of applications. Everything from lyses of E. coli cells to spot cleaning of dirty lab ware can be performed easily, quickly and reproducibly.

In liquid, the rapid (i.e., 20 KHz) vibration of the horn probe tip causes cavitations, the formation and violent collapse of microscopic bubbles.

The collapse of the thousands of cavitations bubbles releases tremendous energy into the liquid form of shock waves.

Objects and surfaces that are within or near the cavitations field are “processed” by the released energy.

The choices of a generator (and transducer) and horns/probes are matched to the volume, viscosity and other parameters of the particular application.

Our Ultrasonic Generator is highly sophisticated electronic device that automatically adjust the power level to meet the level of resistance produced by the specific application. Transducers utilize carefully selected piezo-electric crystals to transform the electrical signal to mechanical vibration. The Horns/Probes are crafted from high quality titanium or aluminum.

US equipment | Frequency (KHz) | Ultrasound Output(W) | Total Length (mm) | Diameter (mm) | Static Capacity (pF±10%) |

ARS-HLCSB-1000

| 15-28 | 1000

| 500

| Φ50-55

| 68000

|

ARS-HLCSB-1500

| 15-28

| 1500

| 850 | Φ50-55

| 68000

|

ARS-HLCSB-2000

| 15-28

| 2000

| 1100 | Φ50-55

| 132000

|

Market application:

* Chinese medicine extraction: refers to the ultrasonic pulverization (breaking) of Chinese medicine cells to achieve high-efficiency extraction of useful substances. Compared with conventional extraction technology, ultrasonic assisted extraction is fast, inexpensive, efficient, safe, low in cost, and widely applicable.

* Biodiesel production: the use of ultrasonic emulsification to prepare a biomass oil-diesel mixed emulsion is actually to disperse the bio-oil droplets into another immiscible diesel liquid. Compared with other technologies, the prepared droplets can be finely dispersed and narrowly distributed, high efficiency, good dispersion effect, and can increase the stability of the emulsion.

* Ultrasonic anti-sea life: It is based on the cavitation effect of ultrasonic. When the tiny bubble core in the liquid is activated under the action of ultrasonic, it is manifested as a series of dynamic processes such as the oscillation, growth, contraction and collapse of the bubble. The bubbles in the liquid generate hundreds of atmospheres and high temperatures of thousands of degrees Celsius at the moment of bursting, which can quickly peel off the attachment of sea creatures and smash the epidermal cells of sea creatures, so as to achieve the purpose of preventing sea creatures.

* Ultrasonic catalysis: The application of ultrasound to the catalytic reaction process can simulate the high-temperature and high-pressure reaction in the reactor on a microscopic scale, providing a very special physical and chemical environment for catalytic reactions that are difficult or impossible to achieve under normal conditions. The catalytic reaction can be carried out in a milder environment. It can further increase the reaction speed, shorten the reaction time, and increase the yield of the target product. The main applications are catalysis on metal surfaces, phase transfer catalyzed reactions, and enzyme catalyzed reactions.

* Sewage treatment: In the process of sewage treatment, ultrasonic cavitation has a strong ability to degrade organic matter, and the degradation rate is very fast, which provides the possibility to degrade harmful organic matter in water, so as to realize the purpose of ultrasonic sewage treatment.

* Ultrasonic dispersion: refers to the process of dispersing and de-agglomerating particles in the liquid through the "cavitation" effect of ultrasonic waves in the liquid using liquid as a medium. Ultrasonic dispersion can be divided into emulsion dispersion (liquid-liquid dispersion) and suspension dispersion (solid-liquid dispersion), and has been applied in many fields. The application of ultrasonic for the dispersion of suspensions includes the dispersion of titanium oxide in water or solvents in the coating industry, the dispersion of dyes in molten paraffin wax; the dispersion of drug particles in the pharmaceutical industry, and the powder emulsion in the food industry Dispersion and so on.

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian