28KHZ 800W Competitive Price Ultrasonic Hand Welder For Welding Hood

1-9 Set

$800.00

≥ 10 Set

$760.00

- Item No.2020110400b0dMOQ1 Set

- Product size48 x 46 x 52 mProduct weight15 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

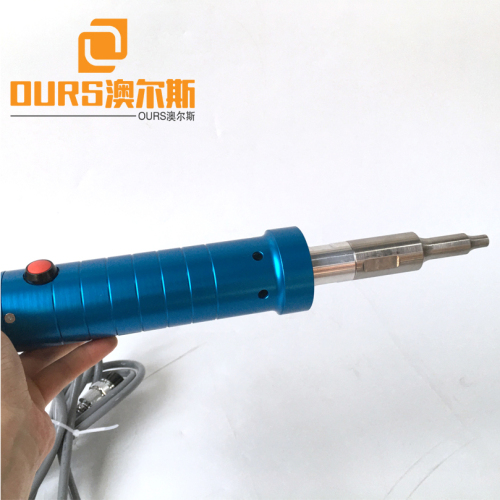

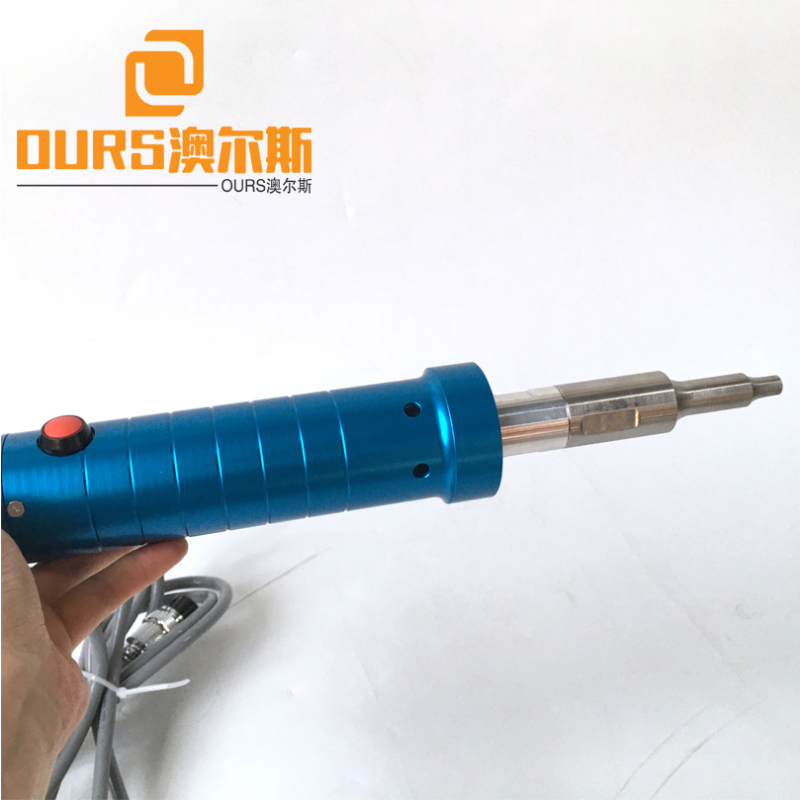

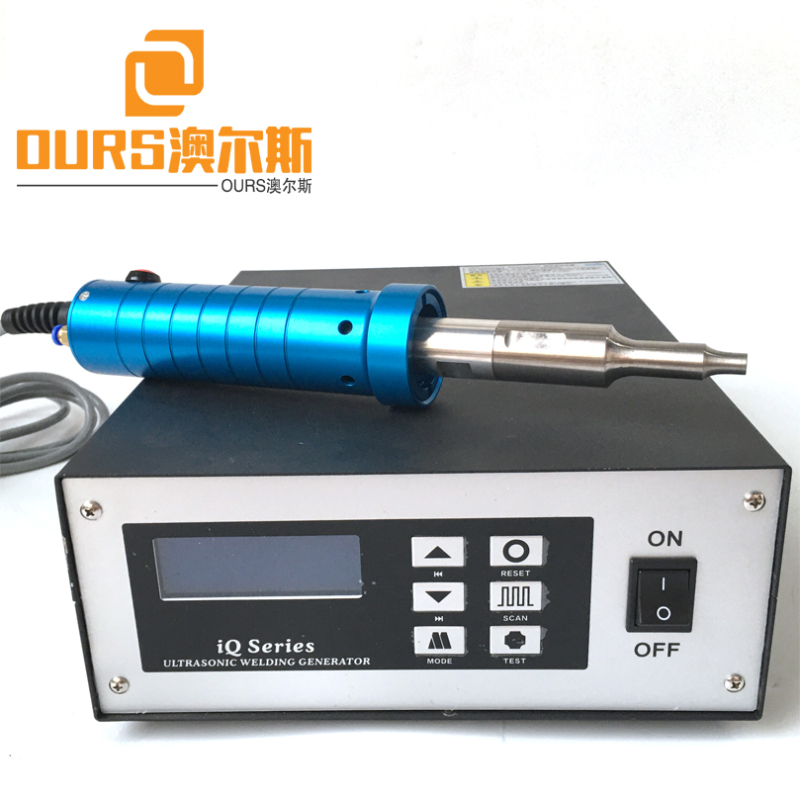

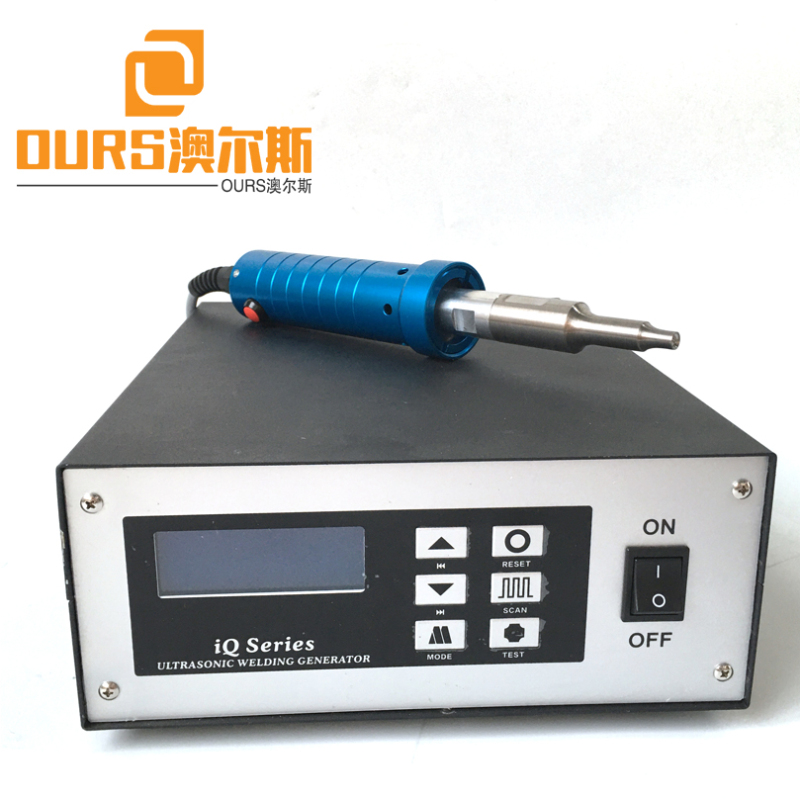

28KHZ 800W Competitive Price Ultrasonic Hand Welder For Welding Hood

![]()

Portable spot welding machines are widely used in the clothing industry, trademark industry, automotive industry, plastic electronics, and household goods industries.

Apparel industry: sewing process of underwear and underwear, welding of webbing elastic band, etc .; can be used for spot drilling.

Trademark industry: woven ribbons, printed ribbons, etc.

Automotive industry: door sound insulation cotton, wiper seat, engine cover, water tank cover, etc.

Plastic electronics: small plastic parts riveting, etc.

Houseware industry: fiber cotton spot welding and so on.

Ultrasound application

Decoration, ribbon spot welding, riveting, etc. are mainly used in textiles, clothing, electronics, toys and other industries. They have the advantages of small size and flexibility, easy operation, and high price.

Machine performance:

1. The machine is small and flexible in design and easy to operate.

2. It can be used for welding of flat, inner / outer ear bands, cup masks, duckbill type and other special-shaped masks.

3. After the mask body is manufactured, the ear bands are welded manually, the operation is simple, and the contacts are firm and beautiful. Skilled workers can weld 10-12 pieces of mask earbands per minute.

Principle of Ultrasonic Plastic Welding:

Ultrasonic plastic welders operate by inducing ultrasonic frequencies in plastic components that is converted into heat between the welded plastic laminates. Frictional heat is produced so that thermoplastic parts melt and an insoluble connection between parts is forged in a very short period of time. The melting points of both working pieces are nearly equivalent which helps to form a uniform weld area. The welded area is usually as strong as the matrix material.

Ultrasonic plastic welding utilizes high frequency, vertical motion to produce heat and the flow of thermoplastic material at the interface of mated parts. Pressure is maintained after the delivery of energy is stopped to allow re-solidification of interwoven plastic at the joint, securing the parts with a homogeneous or mechanical bond. This process offers an environmentally friendly means of assembly as opposed to conventional adhesives or mechanical fasteners.

Ultrasonicspotwelding machine

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-300 | 300W | 15khz |

ARS-DHJ-300 | 300W | 20khz |

ARS-DHJ-300 | 300W | 28khz |

ARS-DHJ-300 | 300W | 35KHz |

ARS-DHJ-300 | 300W | 40khz |

ARS-DHJ-500 | 500W | 15khz |

ARS-DHJ-500 | 500W | 20khz |

ARS-DHJ-500 | 500W | 28khz |

ARS-DHJ-500 | 500W | 35KHz |

ARS-DHJ-500 | 500W | 40khz |

ARS-DHJ-800 | 800W | 15khz |

ARS-DHJ-800 | 800W | 20khz |

ARS-DHJ-800 | 800W | 28khz |

ARS-DHJ-800 | 800W | 35KHz |

ARS-DHJ-800 | 800W | 40khz |

ARS-DHJ-900 | 900W | 15KHz |

ARS-DHJ-900 | 900W | 20khz |

ARS-DHJ-1000 | 1000W | 15KHz |

ARS-DHJ-1000 | 1000W | 20khz |

![]()

28KHZ 800W Competitive Price Ultrasonic Hand Welder For Welding Hood

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian