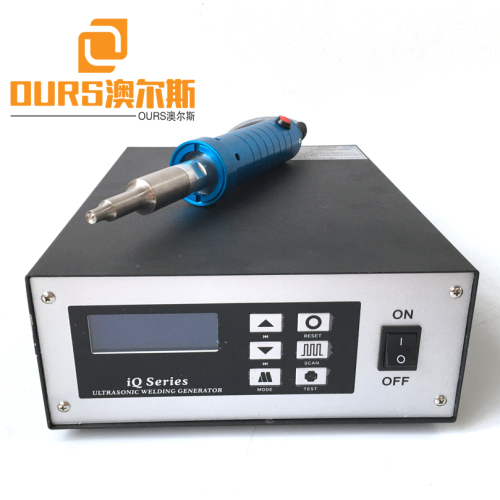

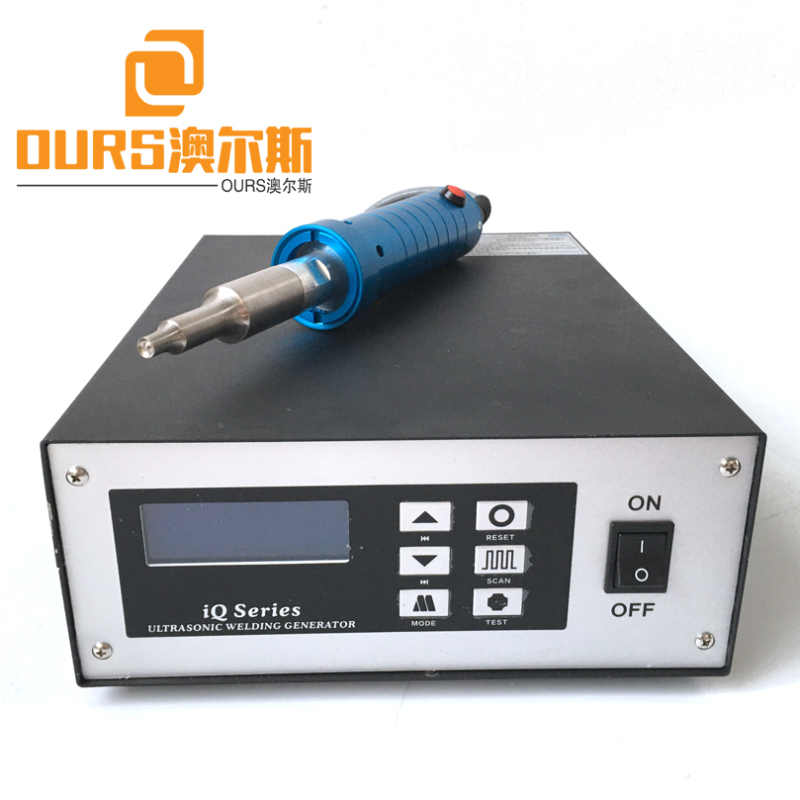

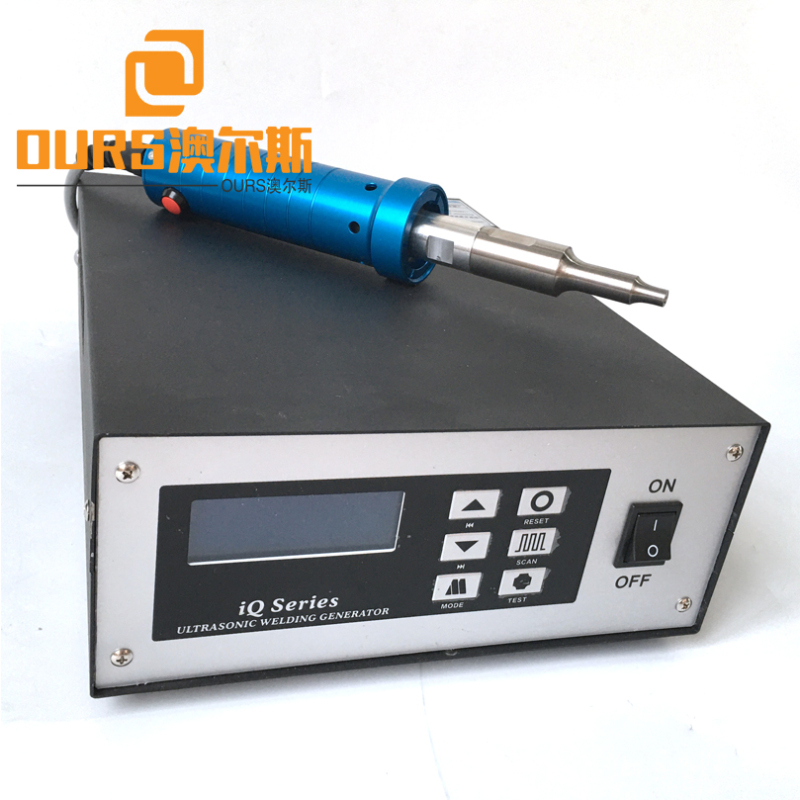

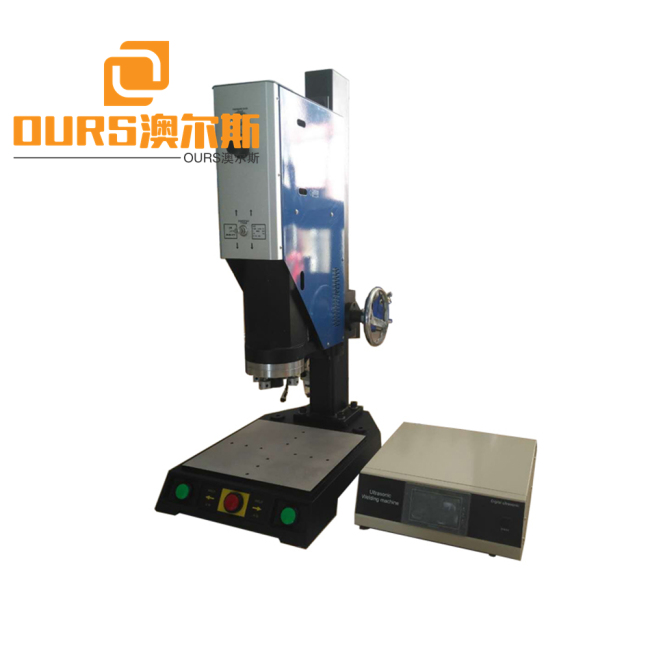

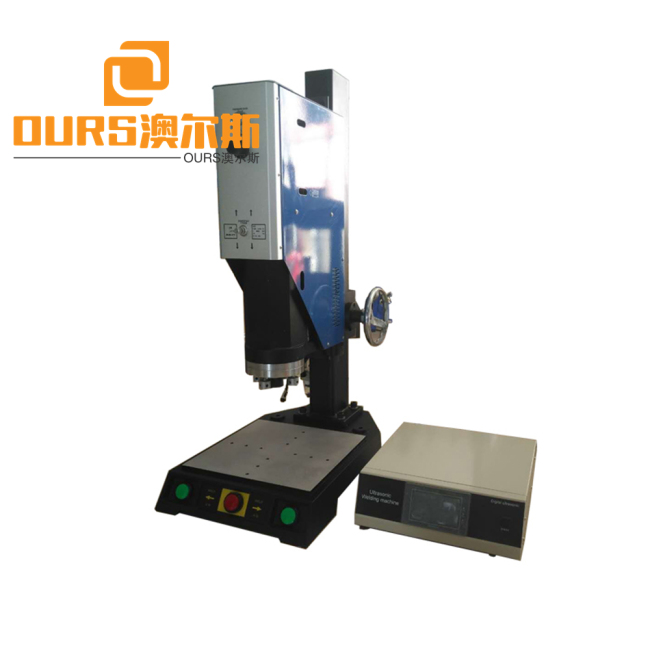

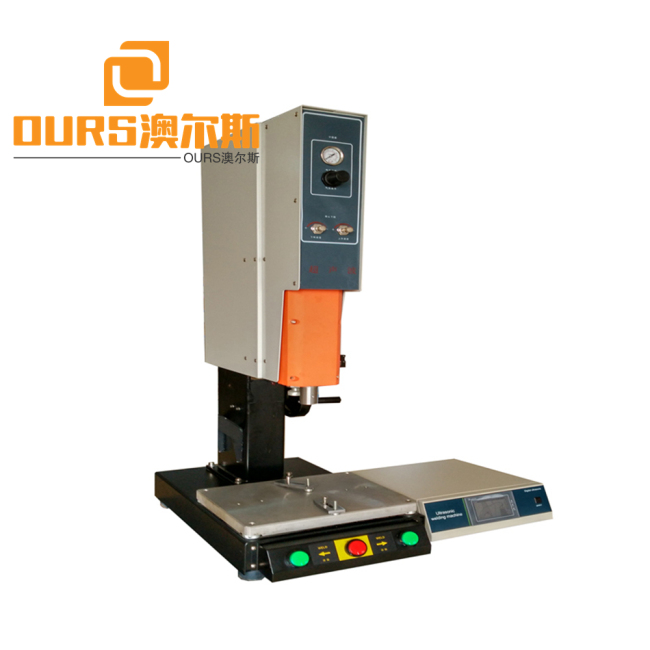

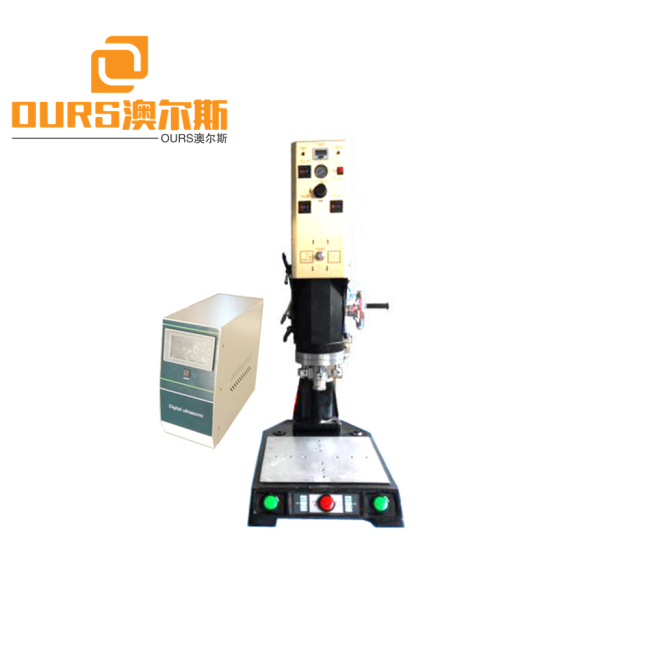

28KHZ 800W Portable Ultrasonic Hand Welding Machine For Manure Belt Repair

1-9 Set

$800.00

≥ 10 Set

$760.00

- Item No.202011041744aMOQ1 Set

- Product size48 x 46 x 52 mProduct weight15 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

28KHZ 800W Portable Ultrasonic Hand Welding Machine For Manure Belt Repair

![]()

The hand-held sonotrode for ultrasonic welding (bonding) is light and handy, suitable for left- or right-handed operation. It is equipped with simple air-cooling system, which prevents the device from heating and the palm from sweating and this way facilitates the control and precise operation.

The ultrasonic hand-held sonotrode is equipped with an ultrasonic generator type. The horn and the handle are made of high—quality materials, that ensure long life and smooth operation.

Basic characteristics:

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

Ultrasonic hand welder offers a low cost solution for parts where automation is not viable or production volumes are low. Application areas include spot-welding, staking of components, access to difficult weld areas and second operations/re-work.

The design and lightness of the manual pistol handgrip have been carefully delineated in order to assure a practical and comfortable handling when in use.

Ultrasonic welding guns are used to weld thermoplastic, where areas of welding are hard to reach the parts are too bigger to weld.

I. Welding method: Welding heads vibrating with ultrasonic waves and ultra-high frequencies under moderate pressure will cause frictional heat to be generated on the joint surface of two plastics and instantly melt the joints. The welding strength can be comparable to the body. Suitable workpieces and reasonable interfaces Designed to achieve water and air tightness, and avoid the inconvenience caused by the use of auxiliary products, to achieve efficient and clean welding (details such as?)

Second, the riveting welding method: Ultrasonic and ultra-high frequency vibration welding head, press the protruding tip of plastic products, make it instantaneously heat and melt into a rivet shape, mechanically riveting materials of different materials together. 3. Implantation: Through the preaching of the welding head and appropriate pressure, the metal parts (such as nuts, screws, etc.) are squeezed into the plastic holes reserved in a moment, and fixed at a certain depth. After completion, no matter the tensile force or the torque can be comparable. The strength of traditional molding in the mold can avoid the disadvantages of the injection mold being damaged and slow injection.

4. Forming: This method is similar to the riveting method. The concave welding head is pressed against the outer ring of the plastic product. After the welding hair emits ultrasonic and ultra-high frequency vibration, the plastic is melted and formed to cover the metal object to fix it. The appearance is smooth and beautiful. This method is mostly used in the fixing of electronics, speakers, and lenses of cosmetics.

V. Spot Welding: A. Welding of two plastic sub-points does not need to design a welding wire in advance to achieve the purpose of welding. B. Perform spot welding on relatively large workpieces, which are difficult to design the welding line, to achieve the welding effect, and can spot weld multiple points at the same time.

6. Cutting and Sealing: The principle of instantaneous vibration of ultrasonic waves is used to cut chemical fiber fabrics. Its advantages are that the cuts are smooth and not cracked or brushed.

Product Specifications :

1 - hand welder can be applied to a single point welding, screw implants , riveting .

2 - Portable design , save space , easy to operate.

3 - can be used independently , but also can be used with automatic peripheral equipment .

4 - There are lessons device models , especially for rhinestones / PC drill mount in haute couture processing .

Ultrasonicspotwelding machine

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-300 | 300W | 15khz |

ARS-DHJ-300 | 300W | 20khz |

ARS-DHJ-300 | 300W | 28khz |

ARS-DHJ-300 | 300W | 35KHz |

ARS-DHJ-300 | 300W | 40khz |

ARS-DHJ-500 | 500W | 15khz |

ARS-DHJ-500 | 500W | 20khz |

ARS-DHJ-500 | 500W | 28khz |

ARS-DHJ-500 | 500W | 35KHz |

ARS-DHJ-500 | 500W | 40khz |

ARS-DHJ-800 | 800W | 15khz |

ARS-DHJ-800 | 800W | 20khz |

ARS-DHJ-800 | 800W | 28khz |

ARS-DHJ-800 | 800W | 35KHz |

ARS-DHJ-800 | 800W | 40khz |

ARS-DHJ-900 | 900W | 15KHz |

ARS-DHJ-900 | 900W | 20khz |

ARS-DHJ-1000 | 1000W | 15KHz |

ARS-DHJ-1000 | 1000W | 20khz |

![]()

28KHZ 800W Portable Ultrasonic Hand Welding Machine For Manure Belt Repair

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian