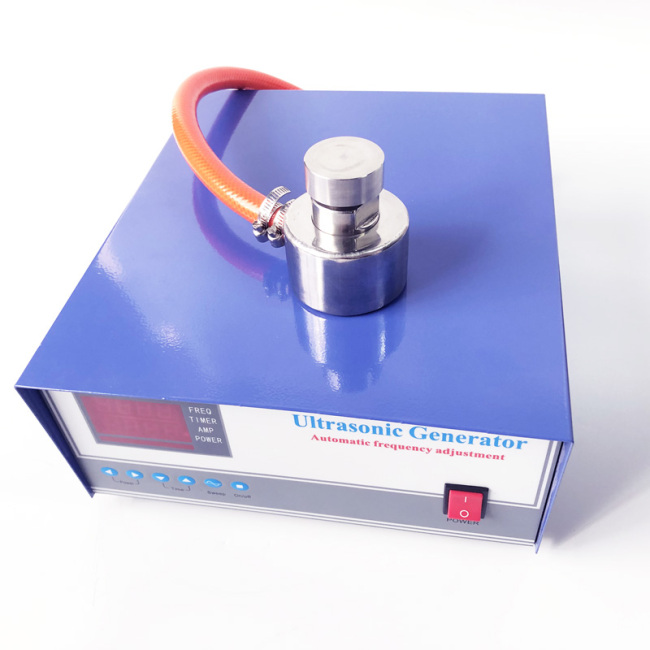

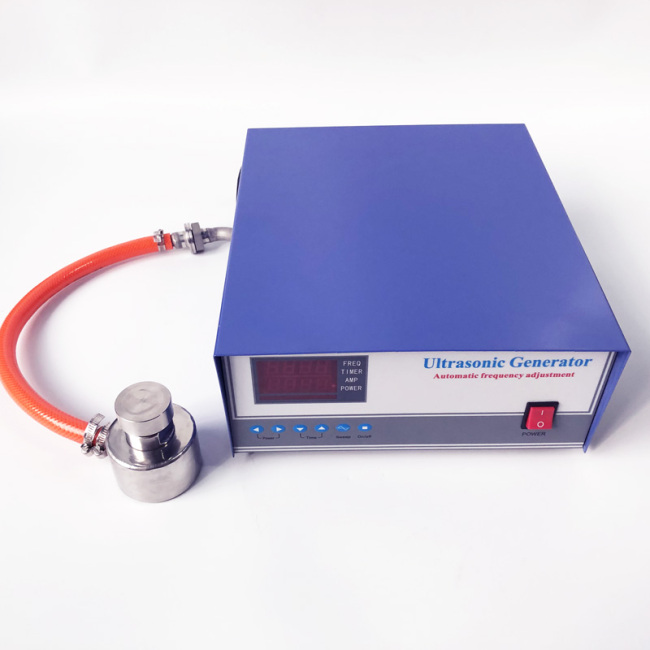

33KHZ Ultrasonic High Frequency Vibration And Generator For Sieving Friction Powder

1-9 Set

$550.00

≥ 10 Set

$530.00

- Item No.20210612be544MOQ1 Set

- Product size48 x 46 x 35 cmProduct weight18 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

33KHZ Ultrasonic High Frequency Vibration And Generator For Sieving Friction Powder

Ultrasonic Vibrating screen is a new vibration sieve which combines ultrasonic vibration together with mechanical vibration of rotary vibration sieve.The principle is passed to the ultrasonic high frequency vibration,through guide ring to entire screen get the purpose of rapid screening material. The principle of ultrasonic vibration transducer is to be prestressed to offset the piezoelectric ceramic swelling stress so as to get high frequency, high strength and the large amplitude of mechanical vibration and achieve the purpose of convert electrical energy into mechanical energy. Because ultrasonic vibration screen should be in air for a long and continue working,transducers are requested has a high amplitude, low heat, high reliability performances. At same time also need high demand for structure of materials and related technology.

The ultrasonic vibration sieve is a simple, practical, and reliable screening system, is the most effective solution in the current powder vibration. Fine sieve filter industry can be widely used in the pharmaceutical, metallurgy, chemical industry, mineral processing, food and other requirements of high precision screening filter effectively solve the reunion, static, strong absorption jam mesh screening problems, domestic sieve sub-industry is a major technological breakthrough.

Ultrasound resonant power supply: 38KHz high frequency high power ultrasonic resonant power supply. Built-in micro-computer chip can automatically track the whole digital frequency according to the different states of ultrasound, without manual adjustment, and it is simple and convenient to operate. The oscillator with long working time has low calorific value and stable working condition.

Type | Frequency(KHz) | Input Power(W) | Ultrasonic transducer |

ARS-ZDS-100W | 33K,35K | 100W | 1 |

ARS-ZDS-200W | 33K,35K | 200W | 2 |

ARS-ZDS-300W | 33K,35K | 300W | 3 |

33KHZ Ultrasonic High Frequency Vibration And Generator For Sieving Friction Powder

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian