35KHZ Factory Price Ultrasonic Spot Welding Machine For Welding Titanium Glasses Frame

1-9 Set

$800.00

≥ 10 Set

$760.00

- Item No.2020110418f46MOQ1 Set

- Product size48 x 46 x 52 mProduct weight15 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

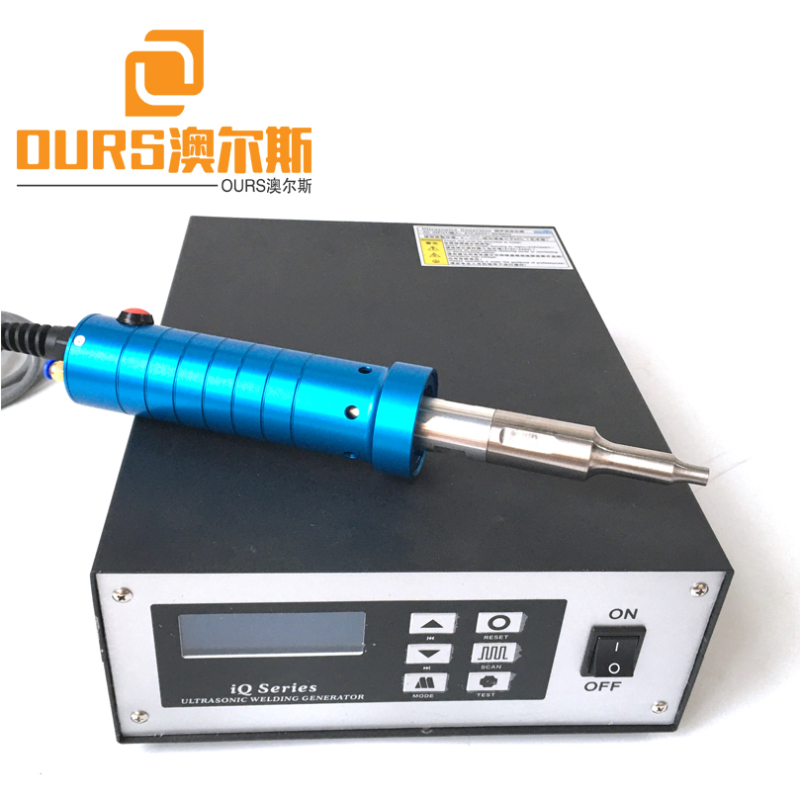

35KHZ Factory Price Ultrasonic Spot Welding Machine For Welding Titanium Glasses Frame

![]()

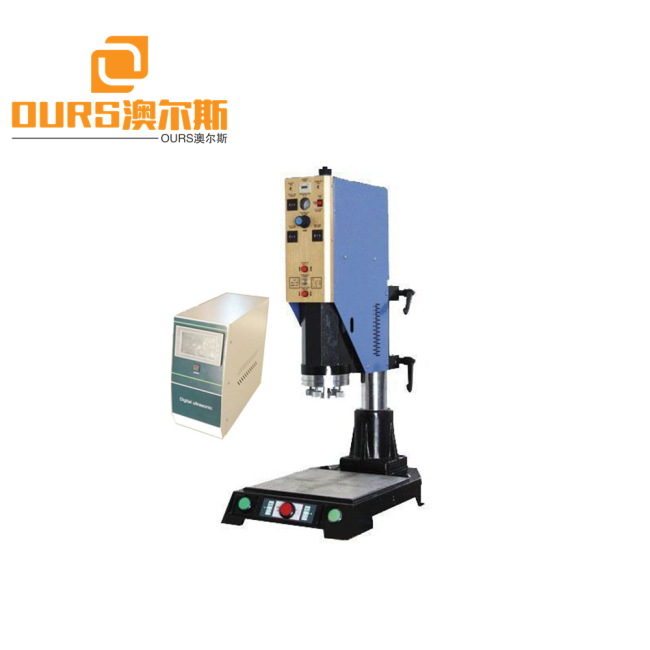

The temperature of the interface is raised by the friction between the surface of the workpiece and the inner molecules.When the temperature reaches the melting point of the workpiece itself, the workpiece interface will melt quickly, and then fill the gap between the interfaces. When the vibration stops, the workpiece will be cooled and fixed at a certain pressure, and then the welding will be achieved.

No flux and external heating are needed, no deformation due to heat, no residual stress, and low requirements for pre-weld treatment on the surface of the weldment. Not only similar metals but also dissimilar metals can be welded. Sheets or filaments can be welded to thick plates. Ultrasonic welding of good electrical conductors has much less energy than current welding, and is often used for welding the leads of transistors or integrated circuits. When used for sealing welding of medicines and explosive materials, it can avoid general welding contamination of medicines due to dissolved objects, and will not explode due to heat.

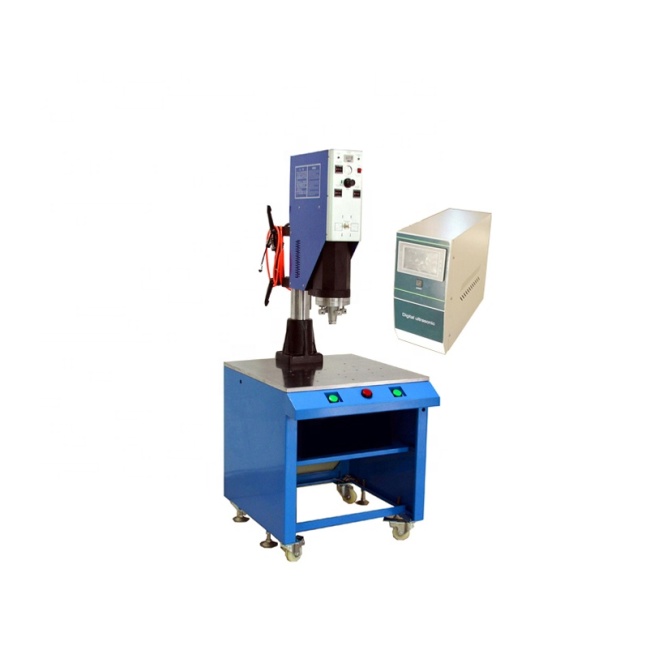

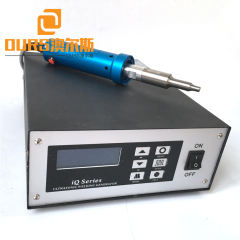

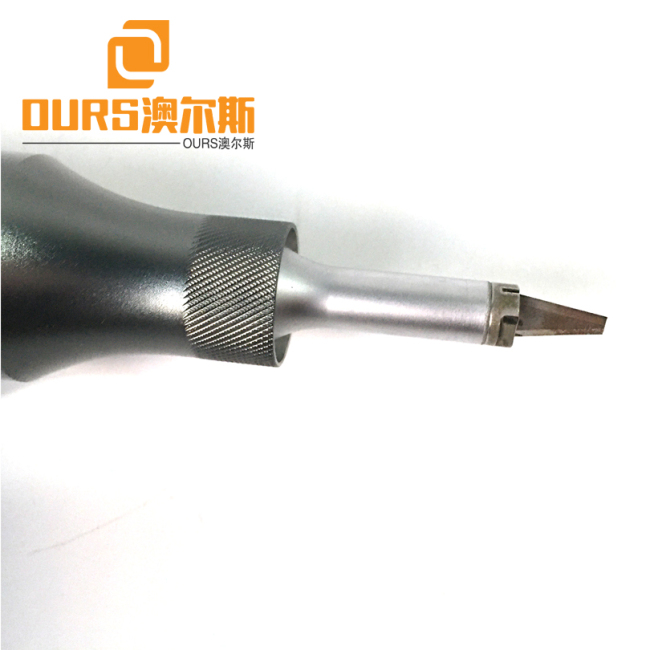

The handheld ultrasonic welding machine can also be used for the welding, riveting, spot welding of thermoplastic products, and the inlaying and blanking processes between metal and plastic parts. It eliminates the backward process of pasting with organic chemical melting point agents, which has energy consumption. Low, high efficiency, no deformation, no pollution, solid welding, easy operation and so on. The handle can also be made into a pistol style. By pressing the plastic part by holding the part and pressing the ultrasonic switch at the same time, ultrasonic waves can be emitted for welding. Studies have shown that the use of handheld ultrasonic welding machines for welding in the plastics industry has become increasingly common around the world. Because the application of this technology can replace the flux, adhesive, buckle or other mechanical fixing methods required in the past, it improves production efficiency and reduces costs.

Plastic hardware, riveting, spot welding, folder positioning, etc.

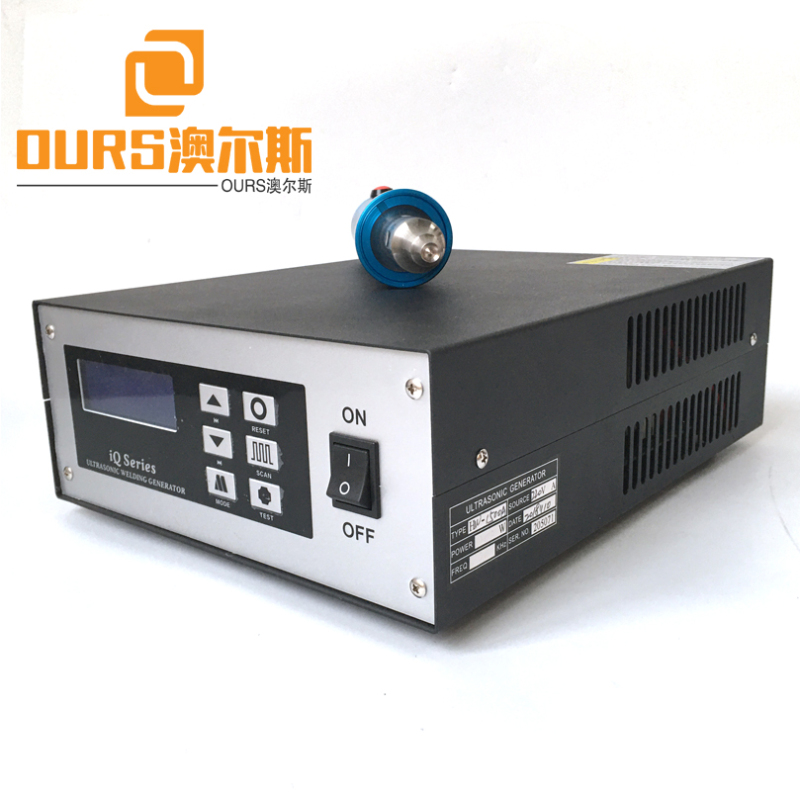

Small in size, convenient to work and does not take up space. Original Japanese transducer with automatic frequency tracking.

Underwear equipment, underwear machinery, ultrasonic, ultrasonic, hand welding machine;

2.Imported CPU and drive unit to ensure reliable power supply.

3.Effectively balance the amplitude while frequency is locked based on the frequency and amplitude control using PID.

4.Power outburst mode, save energy comparing to the traditional ultrasonic hand-held welding machine.

5.Welding amplitude adjustable from 60% to 100% by 1% step.

6.Dual-frequency mode, one can easily switch from one frequency converter to another by software configuration, the frequency setting range is ±8K.

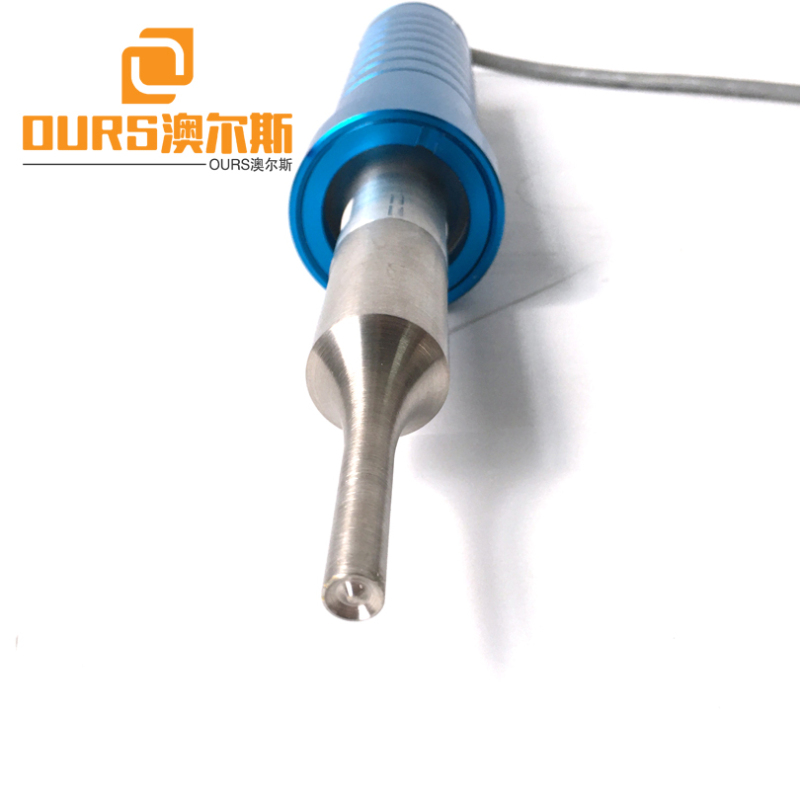

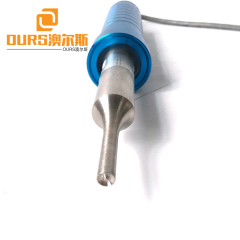

The hand-held sonotrode for ultrasonic welding (bonding) is light and handy, suitable for left- or right-handed operation. It is equipped with simple air-cooling system, which prevents the device from heating and the palm from sweating and this way facilitates the control and precise operation.

The ultrasonic hand-held sonotrode is equipped with an ultrasonic generator type. The horn and the handle are made of high—quality materials, that ensure long life and smooth operation.

Basic characteristics:

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

Product Specifications :

1 - hand welder can be applied to a single point welding, screw implants , riveting .

2 - Portable design , save space , easy to operate.

3 - can be used independently , but also can be used with automatic peripheral equipment .

4 - There are lessons device models , especially for rhinestones / PC drill mount in haute couture processing .

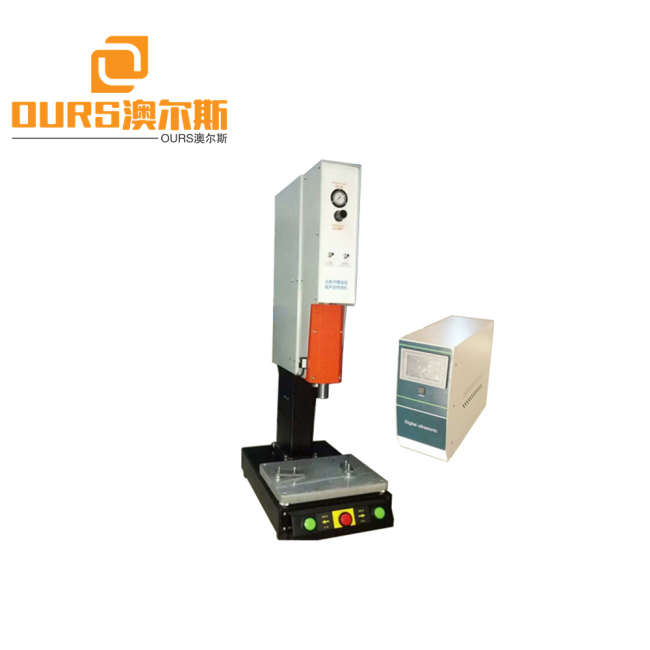

Ultrasonicspotwelding machine

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-300 | 300W | 15khz |

ARS-DHJ-300 | 300W | 20khz |

ARS-DHJ-300 | 300W | 28khz |

ARS-DHJ-300 | 300W | 35KHz |

ARS-DHJ-300 | 300W | 40khz |

ARS-DHJ-500 | 500W | 15khz |

ARS-DHJ-500 | 500W | 20khz |

ARS-DHJ-500 | 500W | 28khz |

ARS-DHJ-500 | 500W | 35KHz |

ARS-DHJ-500 | 500W | 40khz |

ARS-DHJ-800 | 800W | 15khz |

ARS-DHJ-800 | 800W | 20khz |

ARS-DHJ-800 | 800W | 28khz |

ARS-DHJ-800 | 800W | 35KHz |

ARS-DHJ-800 | 800W | 40khz |

ARS-DHJ-900 | 900W | 15KHz |

ARS-DHJ-900 | 900W | 20khz |

ARS-DHJ-1000 | 1000W | 15KHz |

ARS-DHJ-1000 | 1000W | 20khz |

![]()

35KHZ Factory Price Ultrasonic Spot Welding Machine For Welding Titanium Glasses Frame

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian