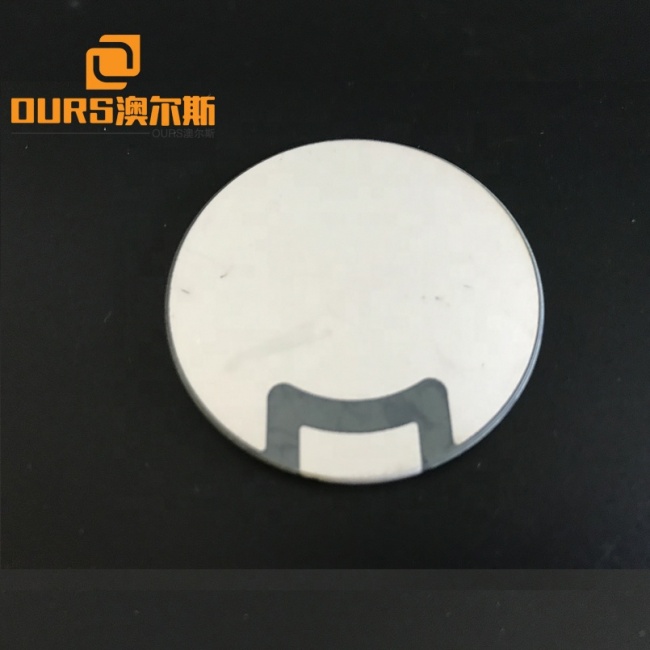

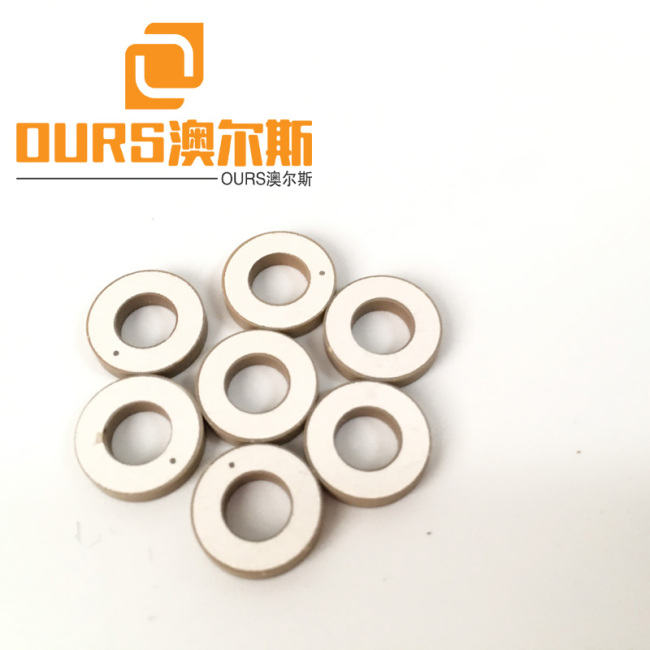

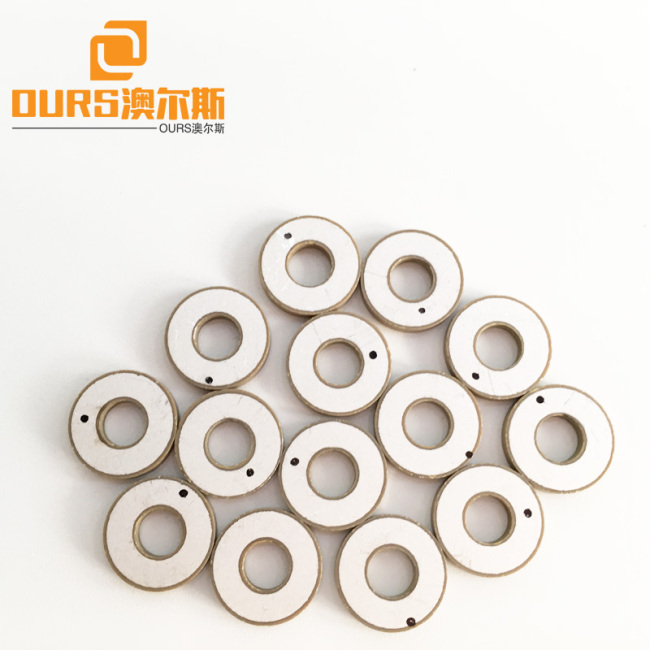

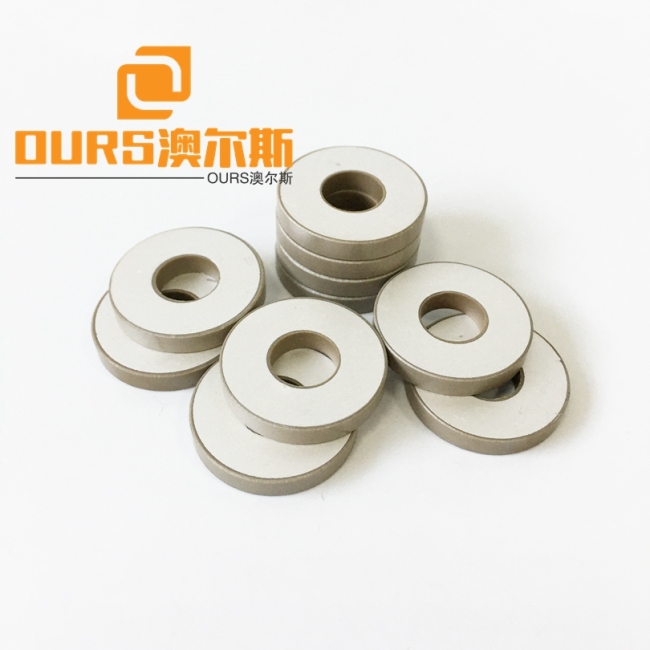

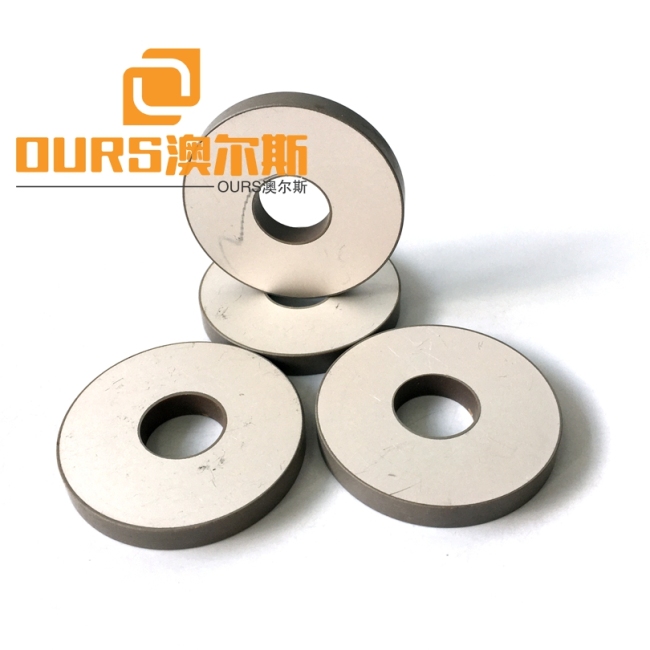

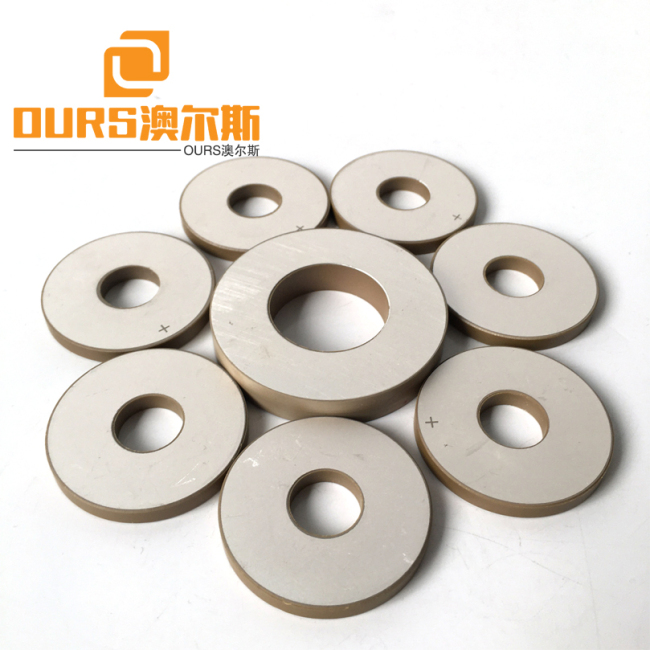

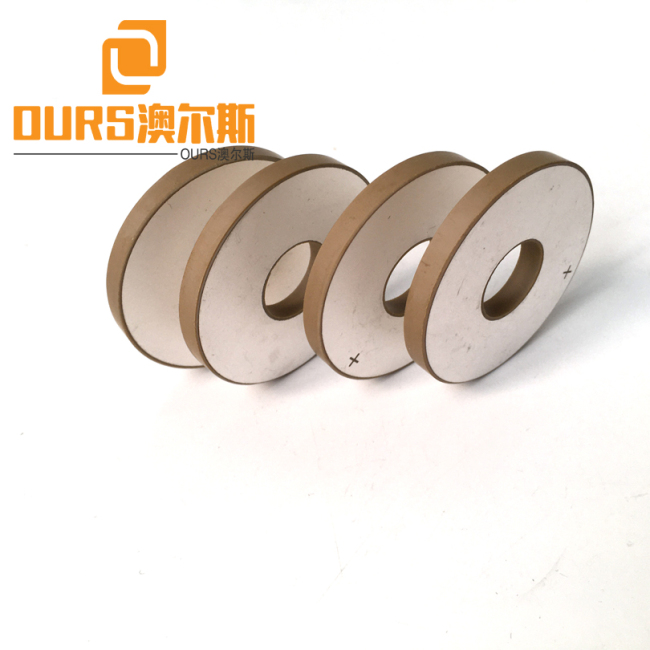

38.1x12x6.35mm High Quality Ring Type Ultrasonic Piezo Ceramic Element For Plant Produce Piezoelectric Cleaning Vibrator

50-999 Piece

$2.00

1000 -2999 Piece

$1.80

≥ 3000 Piece

$1.60

- Item No.ARS-YHJP38126MOQ50 Piece

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Piezoelectric ceramics is a kind of information functional ceramic material that can convert mechanical energy and electrical energy to each other-piezoelectric effect. In addition to piezoelectricity, piezoelectric ceramics also have dielectric properties, elasticity, etc., and have been widely used in medical imaging, Acoustic sensors, acoustic transducers, ultrasonic motors, etc. Piezoelectric ceramics are made by using their materials to cause relative displacement of the positive and negative charge centers inside the material under the action of mechanical stress, resulting in polarization, resulting in the opposite signs of bound charges appearing on both ends of the material, that is, the piezoelectric effect. It has sensitive characteristics. Ceramics are mainly used to manufacture ultrasonic transducers, underwater acoustic transducers, electroacoustic transducers, ceramic filters, ceramic transformers, ceramic discriminators, high-voltage generators, infrared detectors, surface acoustic wave devices, electro-optical devices, In addition to being used in high-tech fields, ignition and piezoelectric gyroscopes are used to serve people in daily life and work hard to create a better life for people.

Commonly used electronic ceramics are barium titanate series, lead zirconate titanate binary system, and the third common compound of AB03 type added to the binary system.

If the ternary system continues to be added, the fourth or more compounds. In this case, quaternary and multi-element electronic ceramics are formed. In addition, there is a kind of metaniobate series, the hard-to-find electronic ceramic types are like "potassium sodium metaniobate" and barium strontium metaniobate (Bax·Sr1-x·Nb2O5) and so on. They do not contain unqualified components such as toxic lead and are beneficial to the environmental protection industry. Therefore, the dielectric properties formed by electronic ceramics are more advocated, reflecting the degree of response of ceramic materials to electromagnetic fields formed inside and outside. Normally, the dielectric constant ε0 is used to indicate that when the external electromagnetic field is not large, the response of the dielectric to the electric field has a usable linearity.

Piezoelectric ceramics Alumina ceramics is the most widely used, most versatile, and most productive ceramic material among oxide ceramics.

According to research reports, there are 12 homogeneous polycrystalline variants of Al203 [1], but there are three main types of alumina ceramics, so their properties are quite different.

In the preparation of Al203 raw materials, if the purity of Al203 is not high, it is generally prepared by chemical methods. Using bauxite as a raw material, through sintering, dissolution, desiliconization, decomposition, calcination and other steps, the Al203 component in the bauxite is dissolved in a sodium hydroxide (Na0H) solution, and the obtained sodium metaaluminate (NaAl02) The solution is cooled to a supersaturated state and hydrolyzed to precipitate aluminum hydroxide (Al(OH)3) precipitation, and then calcined to obtain Al203. However, in the preparation of high-purity Al203 raw materials, organic aluminum salt plus hydrothermal decomposition method, aluminum water discharge oxidation method, aluminum sulfate and ammonia carbonate thermal decomposition method, ammonium alum thermal decomposition method, etc. are generally used [3]. At present, most scholars at home and abroad have adopted the ammonium alum thermal decomposition method, because the A1A prepared by this method has high purity, small fineness (below about 1 pm), and narrow particle distribution range and low degree of agglomeration.

Alumina ceramics have the properties of high mechanical strength, high resistivity, good electrical insulation, high hardness and melting point, good corrosion resistance, and excellent chemical stability. It also has good optical properties and ion conductivity under certain conditions. Based on a series of excellent properties of A1A ceramics, it is widely used in machinery, electronics and electricity, chemical engineering, medicine, construction and other high-tech fields.

Application of piezo ceramic

1. ultrasonic cleaning trasnducer

2. ultrasonic welding tansducer

3. ultrasonic beauty transducer

4. ultrasonic underwater transducer

5. ultrasonic immersible transucer

6. ultrasonic screening transducer

7. ultrasonic cutting transducer

8. ultrasonic atomization transducer

9. ultrasonic emulsifier

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian