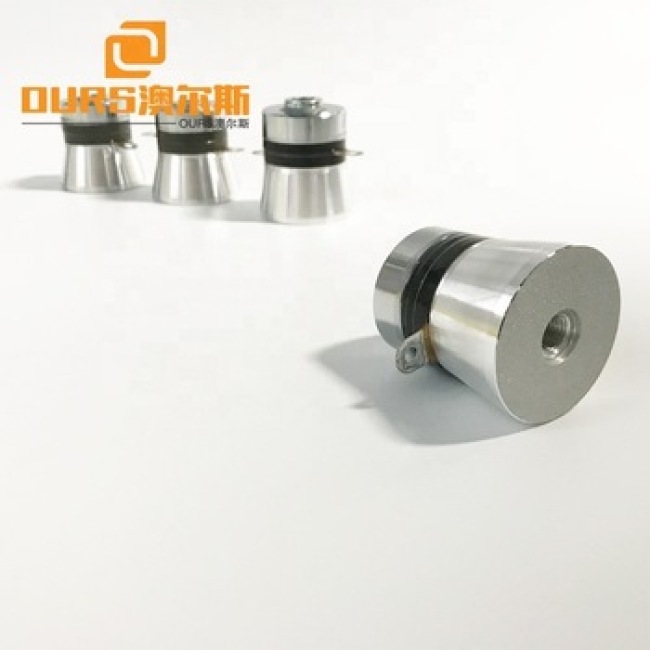

40K 50W 60W 100W Ultrasonic Piezoelectric Sensor Cleaning Transducer As Dental Appliance Washer Parts

1-999 Piece

$10.00

≥ 1000 Piece

$9.00

- Item No.ARS-QXHNQ40100 PZT-4MOQ1 Piece

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Piezoelectric Cleaning Sensor 40K 100W Ultrasound Cleaner Wave Transducer PZT4 Material Industrial Cleaning Transducer With CE

The transducer is an energy converter, which can converted the high frequency, high power current, output of power supply into reciprocating mechanical energy of the ultrasonic vibration, the vibration frequency output of drive power with the same frequency as the current. To further enlarge the amplitude of ultrasonic energy input to the place where we need. Ultrasonic cleaning has become more and more widely used in various industries, agriculture, household equipment, electronics, automobile, rubber, printing, aircraft, food, hospital and medical research.

Principle of ultrasonic vibrator arrangement:

(1) Cleaning different product layouts have different requirements, such as the degree of oil staining of the product, the difficulty of cleaning, the level of cleaning requirements, and the design of the cleaning process, all require targeted selection.

(2) The arrangement of the vibrators is not as dense as possible, and the right one is the best.

3. Introduction to ultrasonic vibrator:

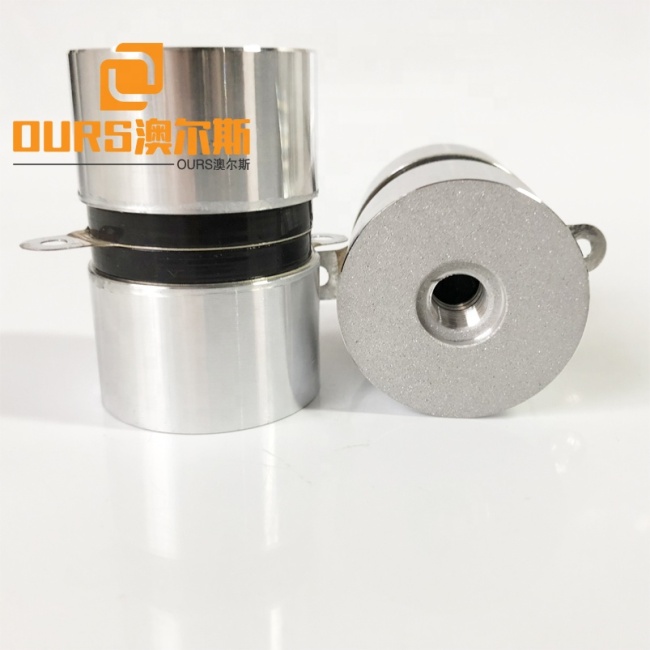

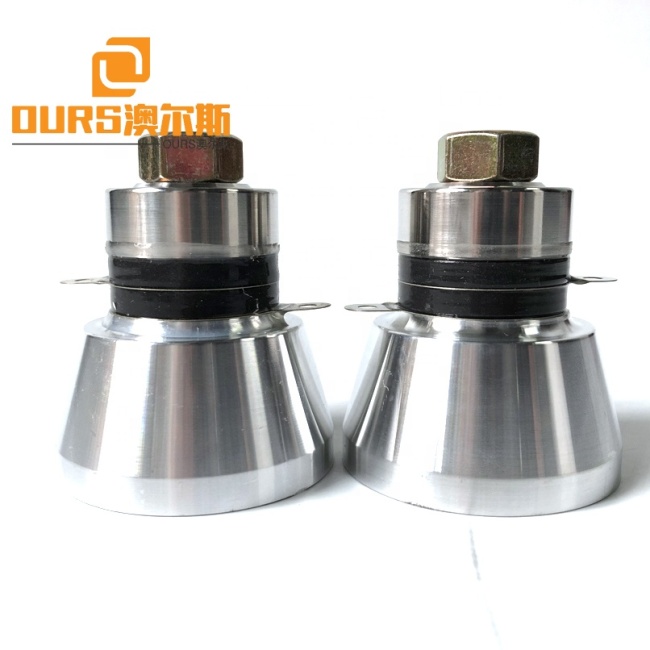

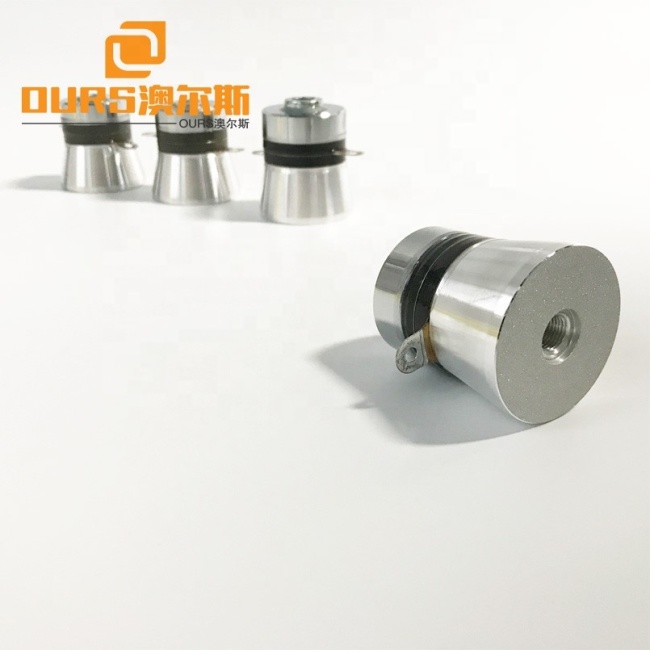

The ultrasonic vibrator, also called the ultrasonic vibrating head, is an ultrasonic transducer and is a core component of the ultrasonic cleaning machine. Industry standard name: Ultrasonic transducer, which belongs to piezoelectric ceramic material and one of the main accessories of ultrasonic cleaning machine. From the power point, a single ultrasonic head is 60W, 100W. The frequencies are: 20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher; the difference in shape is: straight cylindrical shape, horn shape, and the like.

Ultrasonic Transducer classification:

A. piezoelectric chip classification: Black chip P4 series and yellow chip P8 series;

B. Frequency classification: low frequency series (17-23KHz), intermediate frequency series (25-28KHz), medium and high frequency series (33-60KHz) and high frequency series (68-200KHz);

C. Power classification: 30W series (including 35W), 50W series (including 60W), 100W series (including 80W) and other unconventional power;

D. shape classification: straight column and horn type

Ultrasonic Transducer Frequency selection:

The frequency of the transducer is inversely proportional to the wavelength, and the wavelength is related to the diameter of the cavity (strictly speaking, the nucleation time is longer due to the low frequency), and the diameter of the cavity is related to the explosion pressure. The higher the general frequency, the smaller the wavelength, the smaller the diameter of the cavity, the lower the explosion pressure, but the higher the density of the cavity, the better the permeability.

Based on the above principles:

Low frequency (17 ~ 23KHz): When the dirt of the cleaned material is heavy or difficult to be cleaned, and the explosive impact does not cause much damage to the surface of the cleaned material, the low frequency series transducer should be selected. Commonly used industries are: magnetic industry, steam protection industry, textile industry and so on. Note that the noise of this series is large, preferably sound insulation.

Medium frequency (25 ~ 28KHz): If the dirt of the cleaned material is slightly heavy or the cleaning is difficult and moderate, and the explosive impact does not cause much damage to the surface of the cleaned material, the intermediate frequency series transducer should be selected. This series of industries are the most widely used, and are common in machinery processing industry, electroplating industry, catering industry and so on.

Medium and high frequency (33 ~ 60KHz): When the dirt of the cleaned material is light, the cleaning is easy, or the explosive shock damage to the surface of the cleaned material is required, the medium and high frequency series transducer should be selected. Commonly used industries include precision parts, glass glasses, electronic components, circuit boards, etc.

| Specification List | ||||||

| Model | Frequency (KHz) | Capacitance (pF) | Resonance Impedance (Ω) | Size Radiation head*Height (mm) | Power (W) | Insulation resistance (2500VDC) |

| ARS-8QXHNQ-2540 | 40±0.8 | 3100±10% | ≤30Ω | 25*58 | 20w | ≥100MΩ |

| ARS-8QXHNQ-3045 | 46±1.0 | 2400±10% | ≤25Ω | 45*43 | 35w | ≥100MΩ |

| ARS-8QXHNQ-3517 | 17±1.0 | 2550±10% | ≤28Ω | 78*93 | 50w | ≥100MΩ |

| ARS-8QXHNQ-3820 | 20±0.8 | 3800±10% | ≤28Ω | 59*99 | 60w | ≥100MΩ |

| ARS-8QXHNQ-3823 | 23±0.8 | 3800±10% | ≤28Ω | 59*84 | 60w | ≥100MΩ |

| ARS-8QXHNQ-3825* | 25±0.8 | 3800±10% | ≤20Ω | 59*80 | 60w | ≥100MΩ |

| ARS-8QXHNQ-3828* | 28±0.5 | 3800±10% | ≤20Ω | 59*68 | 60w | ≥100MΩ |

| ARS-8QXHNQ-3833* | 33±0.5 | 3800±10% | ≤20Ω | 48*61 | 60w | ≥100MΩ |

| ARS-8QXHNQ-3840* | 40±0.5 | 3800±10% | ≤20Ω | 48*51 | 60w | ≥100MΩ |

| ARS-8QXHNQ-4520* | 21.5±0.8 | 5600±10% | ≤20Ω | 67*92 | 100w | ≥100MΩ |

| ARS-8QXHNQ-4528* | 28±0.5 | 5600±10% | ≤20Ω | 67*68 | 100w | ≥100MΩ |

| ARS-8QXHNQ-5028 | 28±0.5 | 7200±10% | ≤20Ω | 67*68 | 120w | ≥100MΩ |

| ARS-8QXHNQ-5020 | 20±0.5 | 4650±10% | ≤25Ω | 79*94 | 120w | ≥100MΩ |

| ARS-4QXHNQ-2540 | 40±0.8 | 2400±10% | ≤30Ω | 25*58 | 20w | ≥100MΩ |

| ARS-4QXHNQ-2540 | 40±0.8 | 2400±10% | ≤30Ω | 30*50 | 20w | ≥100MΩ |

| ARS-4QXHNQ-2560 | 60±1.5 | 2300±10% | ≤35Ω | 30*35 | 20w | ≥100MΩ |

| ARS-4QXHNQ-2565 | 65±1.5 | 2300±10% | ≤35Ω | 25*31 | 20w | ≥100MΩ |

| ARS-4QXHNQ-3055 | 55±1.0 | 3100±10% | ≤35Ω | 30*45 | 35w | ≥100MΩ |

| ARS-4QXHNQ-3050 | 52±2.0 | 3100±10% | ≤35Ω | 38*40 | 35w | ≥100MΩ |

| ARS-4QXHNQ-3528* | 28 ±0.5 | 4000±10% | ≤20Ω | 45*79 | 50w | ≥100MΩ |

| ARS-4AH-3540* | 40 ±1.0 | 4000±10% | ≤20Ω | 45*55 | 50w | ≥100MΩ |

| ARS-4QXHNQ-3825* | 25±0.8 | 4800±10% | ≤20Ω | 59*80 | 60w | ≥100MΩ |

| ARS-4QXHNQ-3828* | 28±0.5 | 4800±10% | ≤20Ω | 59*68 | 60w | ≥100MΩ |

| ARS-4QXHNQ-3833 | 33±0.5 | 4800±10% | ≤20Ω | 48*62 | 60w | ≥100MΩ |

| ARS-4QXHNQ-3835 | 35±0.5 | 4800±10% | ≤20Ω | 45*55 | 60w | ≥100MΩ |

| ARS-4QXHNQ-3840* | 40±0.5 | 4800±10% | ≤20Ω | 48*51 | 60w | ≥100MΩ |

| ARS-4QXHNQ-4520 | 22±0.5 | 7600±10% | ≤20Ω | 67*92 | 100w | ≥100MΩ |

| ARS-4QXHNQ-4525 | 25±0.5 | 7600±10% | ≤20Ω | 67*76 | 100w | ≥100MΩ |

| ARS-4QXHNQ-4528* | 28±0.5 | 7600±10% | ≤20Ω | 67*68 | 100w | ≥100MΩ |

| ARS-4QXHNQ-4540* | 40±0.5 | 7600±10% | ≤20Ω | 55*53 | 100w | ≥100MΩ |

| ARS-4QXHNQ-5028 | 28±0.5 | 9600±10% | ≤20Ω | 67*68 | 120w | ≥100MΩ |

| ARS-4QXHNQ-3868 | 67±2.0 | 4800±10% | ≤20Ω | 50*65 | 50w | ≥100MΩ |

| ARS-4QXHNQ-3880 | 79±1.5 | 4800±10% | ≤25Ω | 40*54 | 60w | ≥100MΩ |

| ARS-4QXHNQ-38100 | 100±1.5 | 4800±10% | ≤25Ω | 40*57 | 60w | ≥100MΩ |

| ARS-4QXHNQ-38120 | 120±1.5 | 4800±10% | ≤25Ω | 40*58 | 60w | ≥100MΩ |

| ARS-4QXHNQ-35130 | 129±1.5 | 4200±10% | ≤25Ω | 36*54 | 50w | ≥100MΩ |

| ARS4QXHNQ-38160 | 160±1.5 | 4800±10% | ≤25Ω | 40*57 | 60w | ≥100MΩ |

| ARS-4AS-35165 | 165±5.0 | 4100±10% | ≤60Ω | 42*61 | 40w | ≥100MΩ |

| ARS-4AH-25200 | 200±2.0 | 2300±10% | ≤35Ω | 30*35 | 20w | ≥100MΩ |

| Screw hole size (diameter * pitch * depth)M10*1.0*10 | ||||||

40khz/100W Piezoelectric Ultrasonic Cleaning Transducer pzt-4 for industry cleaning machine and ultrasonic cleaning equipment

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian