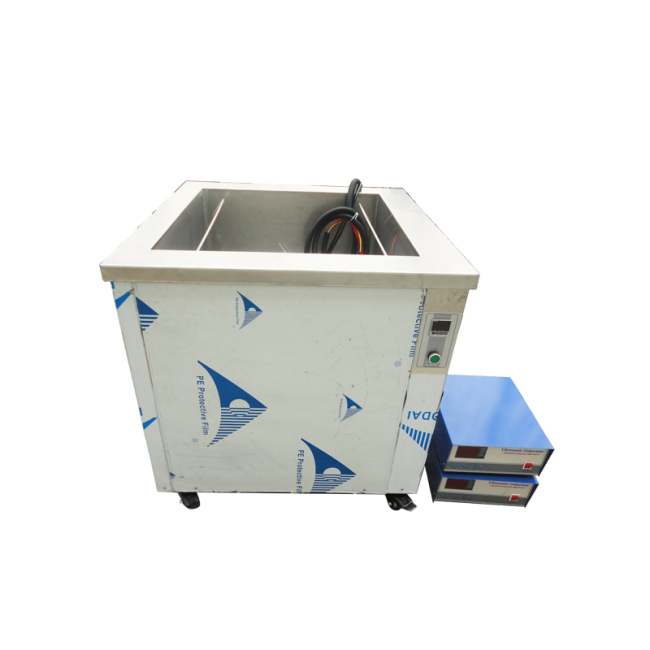

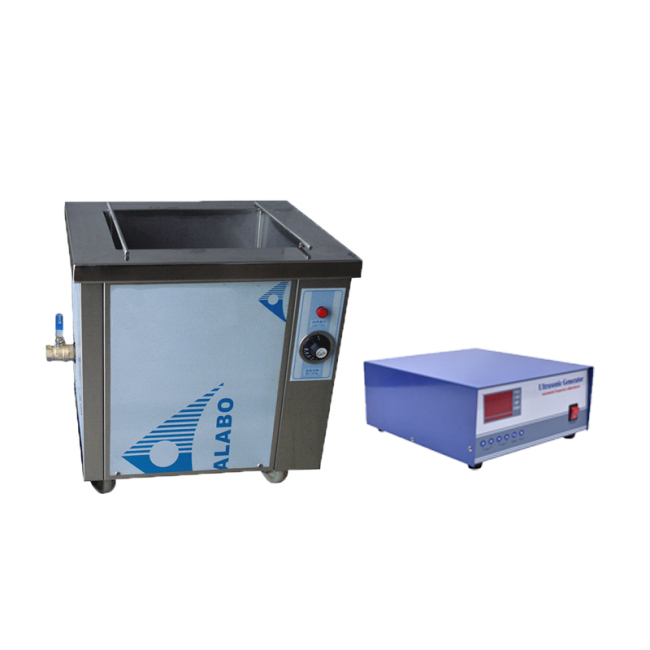

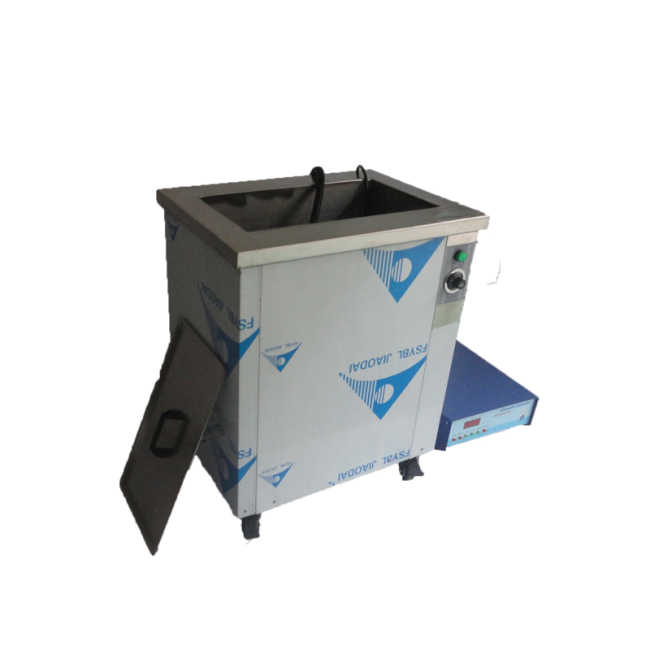

40KHZ 2500W 50L Ultrasonic Cleaning For Cleaning Die Casting Mold

1-49 Set

$6,950.00

≥ 50 Set

$6,850.00

- Item No.20210517f072eMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

40KHZ 2500W 50L Ultrasonic Cleaning For Cleaning Die Casting Mold

Principle of the electrolytic mold cleaning machine: electrolysis is the process of chemical decomposition of substances under the action of electric current. During the electrolysis process, the dirt on the metal surface begins to fall off, and the peeling is accelerated under the impact of ultrasonic waves. The metal surface is stained with animal and vegetable oils, minerals Oil, paraffin, carbon deposit, oxide layer. Use electrolysis to remove these dirt. When the current passes through the mold electrolytic cleaning agent containing a special formula, oxygen is generated near the positive electrode of the electrolytic cell, and hydrogen is generated at the negative electrode. Put the metal parts to be cleaned into the positive electrode of the electrolytic cell, and there will be fines on the metal surface during the electrolysis process. These small bubbles cause the dirt to peel off the metal surface. Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to convert the transducer to mechanical energy from electrical energy. During this process, the transducer transfers huge energy to the cleaning tank solution. , Generate positive and negative pressure zones in the liquid, forming tens of thousands of cavitation bubbles, which continue to form explosions, impact the surface of the cleaned metal object, and quickly release the dirt on the metal surface. To clean the mold and restore the mold True color

Scope of application: plastic molds, hardware molds, optical mirror molds, rubber molds, medical equipment, auto parts molds, etc.

Note: Various non-standard models and sizes can be customized according to customer requirements

1: Description of cleaning process of electrolytic ultrasonic (plastic mold) cleaning machine

The electrolytic ultrasonic system is composed of an ultrasonic generating system, an electrolytic circuit system, a circulating filter system, a control system, a special gold type cleaning fluid and a water-based rust inhibitor.

2: Equipment use: used for cleaning precision plastic molds, hardware, modules, modules, mold cores, inserts, inserts, decontamination, high-temperature carbon deposits, sulfides, gas, degreasing, and rust removal.

Purpose of washing machine

Mainly used for surface cleaning and drying of various precision hardware such as screws, valve bodies, auto parts, etc. The hard substances, oil stains, wax and dust attached to the surface of precision hardware are treated by ultrasonic, relying on the working principle of ultrasonic to separate the attachments from the precision hardware surface, and then after high-pressure spray washing, it can thoroughly clean the hard substances on the precision hardware workpiece Compared with oil, wax, and dust, it can achieve an ideal cleaning effect that cannot be compared with manual cleaning. The use of ultrasonic cleaning has the advantages of fast cleaning speed, good effect, no damage to objects, reduced labor intensity, and cost saving.

The working principle of the multi-slot ultrasonic cleaning machine is to use the mechanical vibration with strong ultrasonic penetration to impact the surface of the workpiece and clean the workpiece with a cleaning agent to make the surface of the workpiece clean. The working process is to manually put the workpiece to be cleaned into the tooling basket, and clean it in sequence according to the cleaning process. After the cleaning is completed, the workpiece is manually taken out. This equipment is easy to operate. Closed appearance, beautiful and generous structure. High cleaning efficiency, consistent cleaning quality, suitable for mass production.

Introduction of industrial ultrasonic multi-tank cleaning machine:

1. All parts in contact with the medium are made of stainless steel, PVC and other anti-rust materials.

2. The design of this machine fully considers the characteristics of different sizes and complex shapes of the parts, and adopts continuous spraying and ultrasonic cleaning. At the same time, the nozzle arrangement is based on the actual situation of the product, and the multi-angle cross arrangement is used, which is beneficial Improve the efficiency and cleanliness of product cleaning.

3. This machine adopts slag removal, oil removal, coarse filtration, fine filtration and other circulating filtration methods in the filtration method to effectively ensure the cleanliness of the cleaning liquid after filtration and avoid secondary pollution.

4. The system adopts continuous-pass cleaning, stainless steel chain conveying, and it is convenient to get up and down the workpiece.

5. Use a water mist collection and condensation system at each opening of the washing machine to effectively solve the water mist phenomenon generated by the washing machine.

product description:

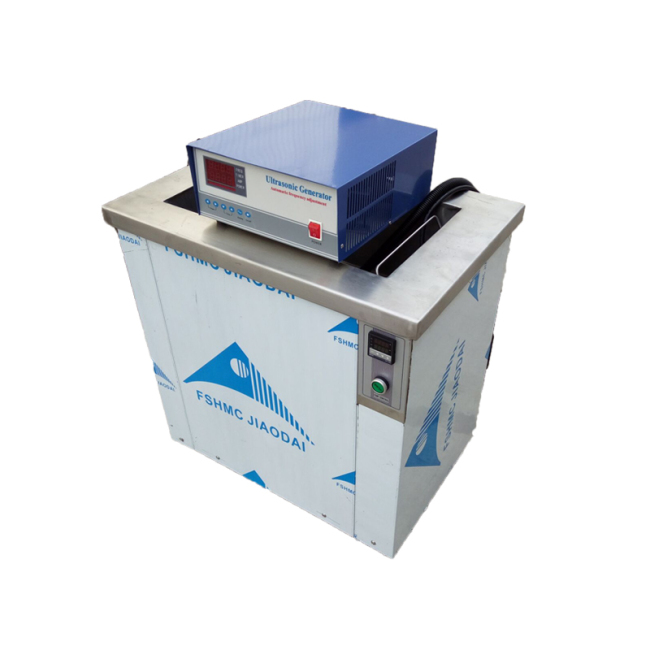

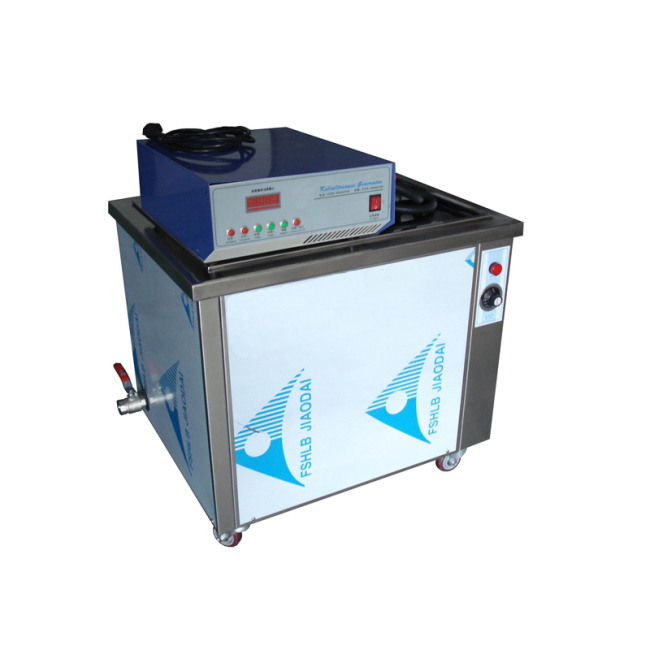

The whole machine is made of stainless steel, with double tank design, which can realize ultrasonic cleaning and ultrasonic rinsing. The equipment has a circulating filter system, oil-water separation mechanism → heating, ultrasonic timing, and can also add oil skimmer, swing function, and automatic lid opening system according to customer needs Wait.

1. Scope of application: electronic parts, electroplating parts, hardware, watches, straps, watch cases, spectacle frames, lenses, jewelry, semiconductor wafers, spinnerets, filter elements, glassware, compressor housings, diesel engine housings , Stainless steel, zinc aluminum alloy polishing, etc. cleaning. Side-vibration ultrasonic is particularly suitable for hanging tool cleaning, and not suitable for using baskets as cleaning tools. Bottom vibration ultrasonic is suitable for using the basket as a cleaning tool.

2. Applicable cleaning agent: neutral, alkaline or weakly acidic water-based solution.

3. Structural features: all imported SUS 304L stainless steel structure, automatic thermostat adjustable from 30℃ to 110℃.

4. Cleaning process: ultrasonic cleaning (electric heating)-rinsing (electric heating)-drying.

5. This equipment can be customized according to customer needs and workpiece characteristics.

Type | Frequency (Khz) | Power(W) | Capacity(L) |

ARS-MJQXJ-18LTT | 28KHZ,40KHZ | 1000W | 18L |

ARS-MJQXJ-20LTT | 28KHZ,40KHZ | 1200W | 20L |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1500W | 30L |

ARS-MJQXJ-40LTT | 28KHZ,40KHZ | 1700W | 40L |

ARS-MJQXJ-50LTT | 28KHZ,40KHZ | 2500W | 50L |

ARS-MJQXJ-60LTT | 28KHZ,40KHZ | 3000W | 60L |

ARS-MJQXJ-70LTT | 28KHZ,40KHZ | 3600W | 70L |

ARS-MJQXJ-80LTT | 28KHZ,40KHZ | 4000W | 80L |

ARS-MJQXJ-100LTT | 28KHZ,40KHZ | 5000W | 100L |

ARS-MJQXJ-115LTT | 28KHZ,40KHZ | 5200W | 115L |

ARS-MJQXJ-400LTT | 28KHZ,40KHZ | 6000W | 400L |

40KHZ 2500W 50L Ultrasonic Cleaning For Cleaning Die Casting Mold

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian