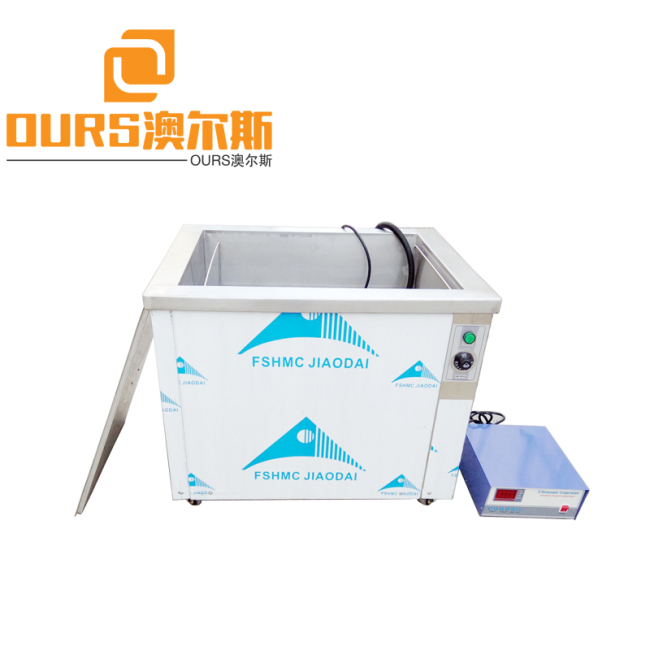

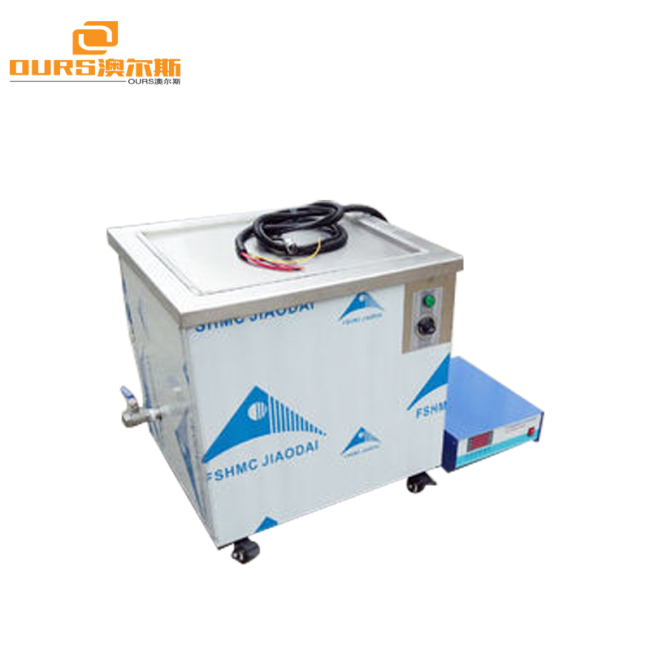

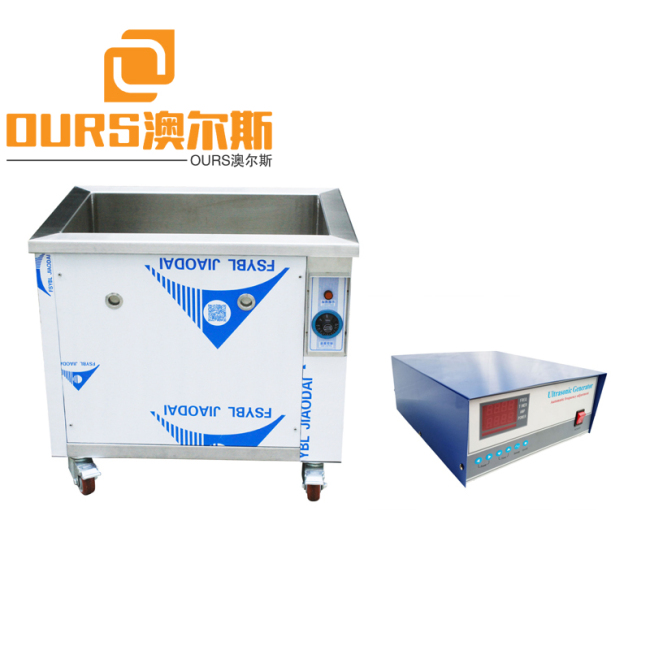

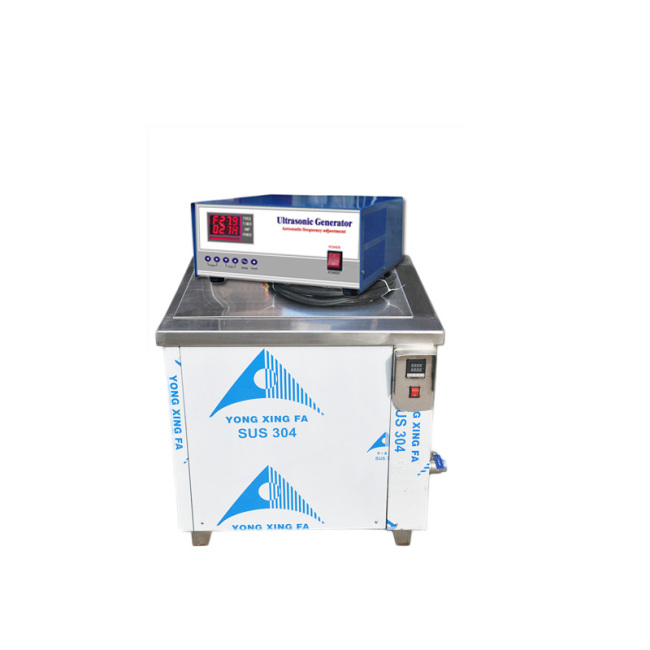

40KHZ Ultrasonic Electrolysis Mold Cleaning Machine For Cleaning Auto Parts Mould

1-4 Set

$6,250.00

≥ 5 Set

$6,150.00

- Item No.20210524ea0e0MOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

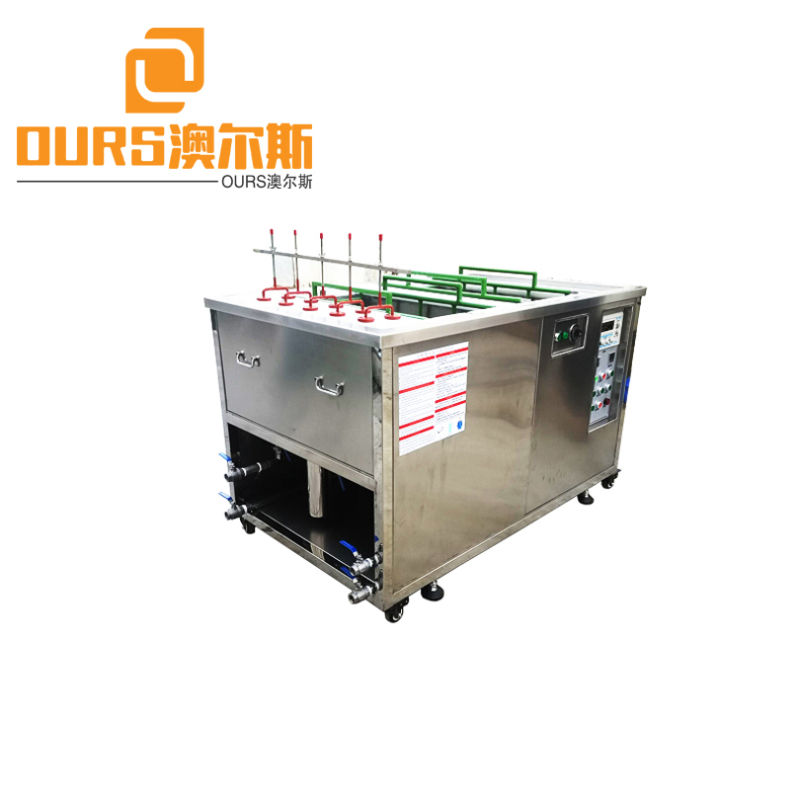

40KHZ Ultrasonic Electrolysis Mold Cleaning Machine For Cleaning Auto Parts Mould

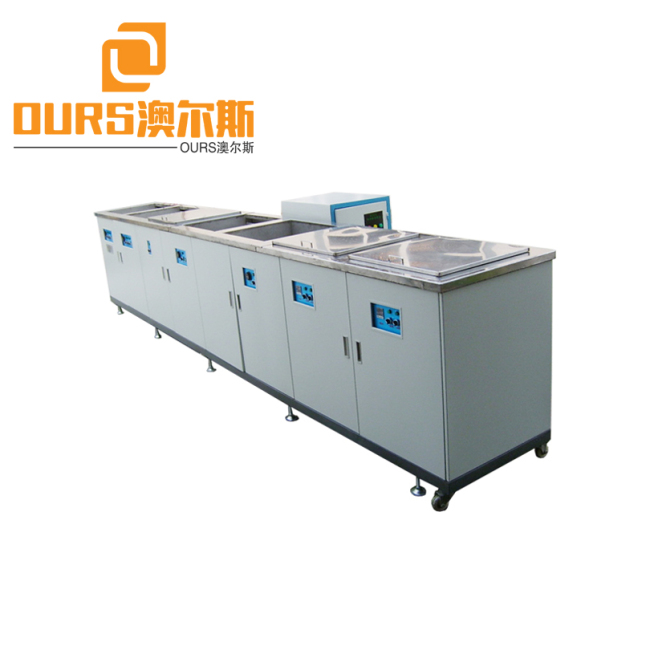

Principle of electrolytic mold cleaning machine: electrolysis is the process of chemical decomposition of substances under the action of electric current. During the electrolysis process, the dirt on the metal surface begins to fall off, and the peeling is accelerated under the impact of ultrasonic waves. The metal surface is stained with animal and vegetable oils, minerals Oil, paraffin, carbon deposit, oxide layer. Use electrolysis to remove these dirt. When the current passes through the mold electrolytic cleaning agent containing a special formula, oxygen is generated near the positive electrode of the electrolytic cell, and hydrogen is generated at the negative electrode. Put the metal parts to be cleaned into the positive electrode of the electrolytic cell, and there will be fines on the metal surface during the electrolysis process. These small bubbles cause the dirt to peel off the metal surface. Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to convert the transducer to mechanical energy from electrical energy. During this process, the transducer transfers huge energy to the cleaning tank solution. , Generate positive and negative pressure zones in the liquid, forming tens of thousands of cavitation bubbles, which continue to form explosions, impact the surface of the cleaned metal object, and quickly release the dirt on the metal surface. To clean the mold and restore the mold True color

A cleaning company that focuses on the mold industry, mainly for the mold industry to solve difficult cleaning problems such as gas, carbon deposits, high-temperature residues, oil, rust, etc., to avoid damage to the mold during manual cleaning, and the ultrasonic electrolytic mold cleaning machine has a fast cleaning time. It can also protect the role of mold repair.

50L liter mold cleaning machine equipment

The mold ultrasonic cleaning machine is also called the electrolytic ultrasonic mold cleaning machine, which is a kind of electrolytic cleaning machine. The mold cleaning machine is mainly composed of an ultrasonic generator system, an electrolytic circuit system, a circulating filter system, a special gold type cleaning fluid and a water-based rust inhibitor. The ultrasonic cleaning machine uses a water-based solvent as a cleaning agent, which is mainly suitable for mold removal Cleaning of oil stains, dust removal, stripping agent and electroplating parts before and after plating. It has a good cleaning effect for all kinds of hardware and machinery parts.

Advantages of mold ultrasonic cleaning machine:

Scope of application of mold ultrasonic cleaning machine:

1. Mold types: injection molds, instrument precision molds, connector molds, precision seal molds, stamping molds, forming molds, etc.

2. Mold gas residual layer, sulfide formed at high temperature, fire-resistant plastic residue, toner residue, mold surface oxide, and various mold rust stains, oil stains, etc.

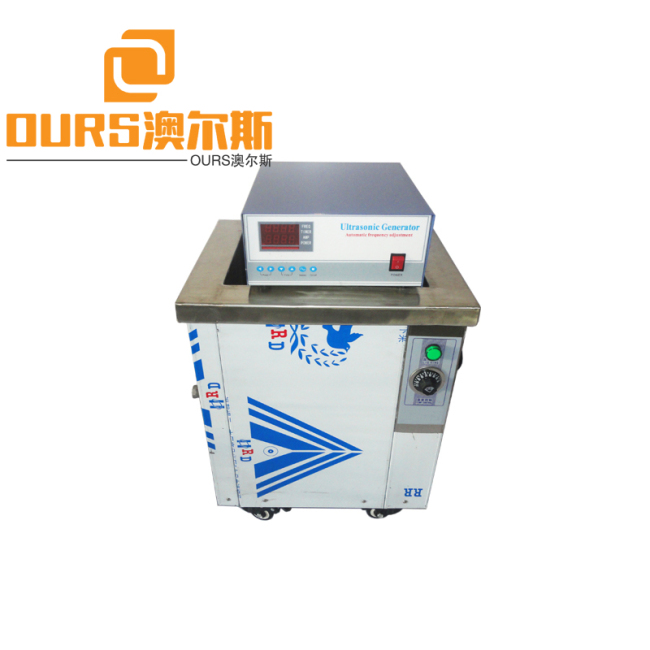

Features of this machine:

1. Imported 304 stainless steel structure, beautiful appearance, acid and alkali resistance.

2. It adopts the most advanced ultrasonic generation technology at home and abroad, with stable performance and long life.

3. Imported high-Q piezoelectric ceramic transducer is adopted, which has high conversion rate and good ultrasonic effect.

4. It adopts split ultrasonic generator and optical fiber high-frequency line transmission, which reduces external interference.

5. Imported ultrasonic transducer adhesive and advanced bonding technology are used to ensure that the transducer will never fall off.

6. Set the solvent heating and temperature automatic constant temperature device, the temperature control range is 0-100 ℃.

7. Continuous work for 24 hours, suitable for mass production.

8. Various size designs can be customized according to customer requirements.

Type | Frequency (Khz) | Power(W) | Capacity(L) |

ARS-MJQXJ-18LTT | 28KHZ,40KHZ | 1000W | 18L |

ARS-MJQXJ-20LTT | 28KHZ,40KHZ | 1200W | 20L |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1500W | 30L |

ARS-MJQXJ-40LTT | 28KHZ,40KHZ | 1700W | 40L |

ARS-MJQXJ-50LTT | 28KHZ,40KHZ | 2500W | 50L |

ARS-MJQXJ-60LTT | 28KHZ,40KHZ | 3000W | 60L |

ARS-MJQXJ-70LTT | 28KHZ,40KHZ | 3600W | 70L |

ARS-MJQXJ-80LTT | 28KHZ,40KHZ | 4000W | 80L |

ARS-MJQXJ-100LTT | 28KHZ,40KHZ | 5000W | 100L |

ARS-MJQXJ-115LTT | 28KHZ,40KHZ | 5200W | 115L |

ARS-MJQXJ-400LTT | 28KHZ,40KHZ | 6000W | 400L |

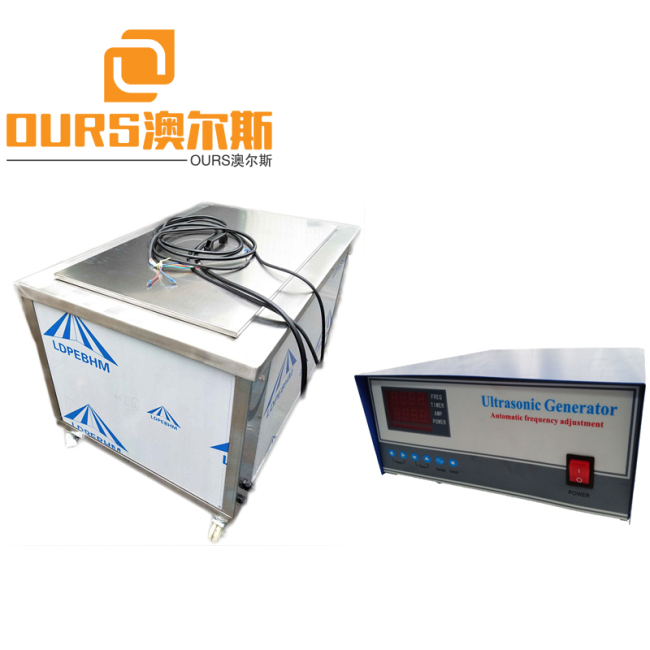

Multi frequency cleaning machine

Type | Power(W) | Frequency (Khz) | Voltage |

ARS-SPQXJ-40khz/80khz | 300W-2400W | 40khz/80khz | 220V-240V/110V-120V |

ARS-TPQXJ-25khz/45khz/80khz | 300W-2400W | 25khz/45khz/80khz | 220V-240V/110V-120V |

ARS-TPQXJ-28khz/40khz/120khz | 300W-2400W | 28khz/40khz/120khz | 220V-240V/110V-120V |

ARS-TPQXJ-28khz/80khz/130khz | 300W-2400W | 28khz/80khz/130khz | 220V-240V/110V-120V |

ARS-TPQXJ-33khz/80khz/135khz | 300W-2400W | 33khz/80khz/135khz | 220V-240V/110V-120V |

ARS-FPQXJ-28khz/60khz/70khz/84khz | 300W-3000W | 28khz/60khz/70khz/84khz | 220V-240V/110V-120V |

ARS-FPQXJ-40khz/77khz/100khz/170khz | 300W-3000W | 40khz/77khz/100khz/170khz | 220V-240V/110V-120V |

Welcome OEM size enquire | |||

40KHZ Ultrasonic Electrolysis Mold Cleaning Machine For Cleaning Auto Parts Mould

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian