68KHZ 60W High Frequency Ultrasonic Vibration Sensor For Cleaning Special high - precision Parts

1-999 Piece

$15.00

≥ 1000 Piece

$13.00

- Item No.20210724e6eb9MOQ1 Piece

- Product size20 x 15 x 15 cmProduct weight2 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

68KHZ 60W High Frequency Ultrasonic Vibration Sensor For Cleaning Special high - precision Parts

Introduction to Ultrasonic Transducers

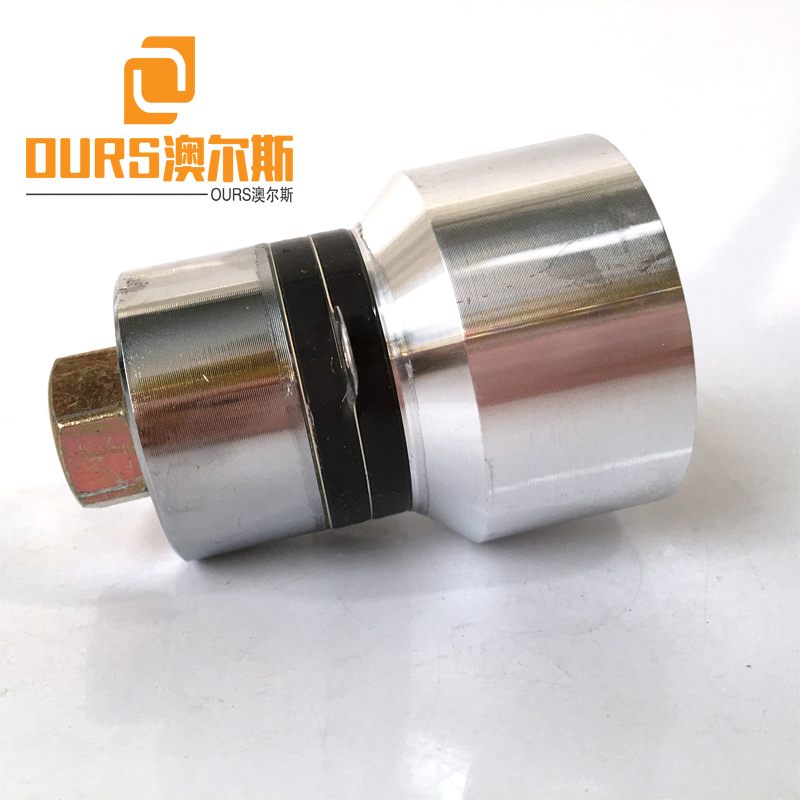

Ultrasonic vibrator, also called ultrasonic vibrator, ultrasonic vibrator, is a kind of ultrasonic transducer and the core component of ultrasonic cleaning machine. We call the whole of ultrasonic transducer and horn connected as vibrator. Ultrasonic transducer is one of the important components in the ultrasonic cleaning machine and ultrasonic vibration plate, which largely determines the quality of the ultrasonic effect.

Our company provides professional ultrasonic transducers with stable quality, high efficiency output and moderate price based on many years of ultrasonic cleaning experience, combined with the opinions and feedback of users.

Ultrasonic transducer is a device that converts high-frequency electric energy into mechanical vibration. The high-frequency electric energy input by the ultrasonic generator is matched with the piezoelectric ceramic sheet of the resonance frequency of the ultrasonic transducer. The electric energy is converted by the piezoelectric effect of the material. Converted into mechanical vibration, that is, ultrasonic vibration, is transmitted to the water medium through the ultrasonic transducer, forming negative pressure bubbles and shock waves in the water, and transmitted in the tax-based solution to achieve the effect of cleaning the surface of the workpiece. The transducer is mainly composed of aluminum block, piezoelectric ceramic sheet and insulating layer.

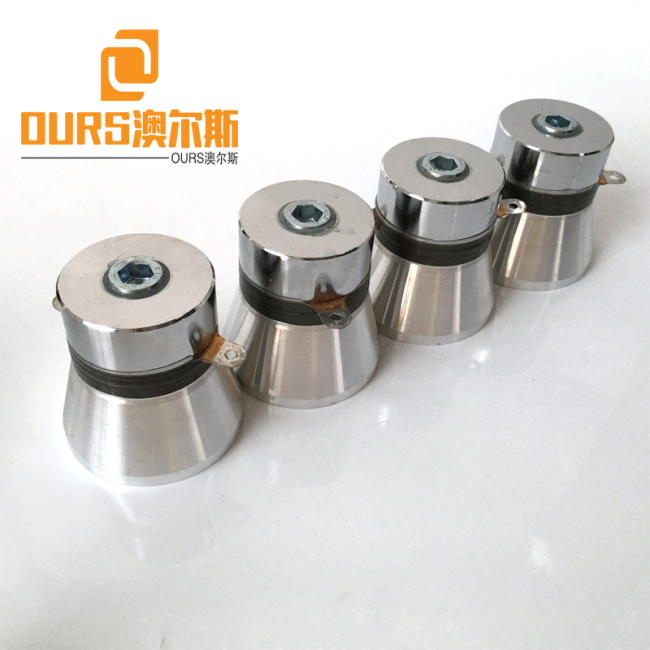

28KHZ/40KHZ/25KHZ/68KHZ/80KHZ/120KHZ/200KHZ and other ultrasonic vibrators (ultrasonic transducers) are widely used in the electronics industry, machinery industry, automotive, electroplating, chemical fiber,

Optical, bearing and other industries. Such as cleaning magnetic cores, oil nozzles, auto parts, electroplating hardware tools, chemical fiber spinnerets, optical lenses, bearings, tools, tableware, medical equipment, precision hardware, watch parts, gold and silver jewelry, electronic components. This frequency has strong vibration and uniform density, which can quickly achieve the purpose of degreasing, sodium removal, decontamination and descaling. In addition, it can also be used in chemical experiments to achieve catalysis, stirring, and rapid generator chemical reactions.

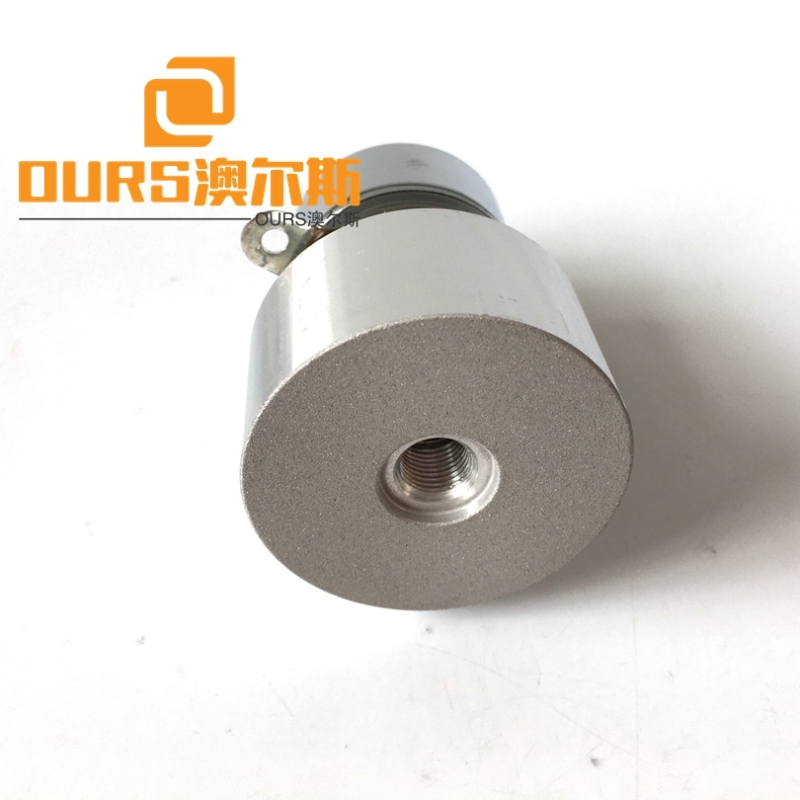

The ultrasonic vibrator produced by our company is a piezoelectric ceramic conversion device that converts high-frequency sinusoidal voltage signals into high-frequency mechanical vibration signals, which are installed on the bottom or side walls of the cleaning tank, and are transmitted through the tank and act on the cleaning medium. The vibration signal of the vibrator is converted into a cavitation effect, and the attachment of the object is quickly peeled off to achieve the purpose of cleaning.

The characteristics of the ultrasonic vibrators produced by the company include low heat generation, good thermal stability, low resonance impedance, good consistency between frequency and static capacitance, and complete and smooth waveforms of frequency and impedance.

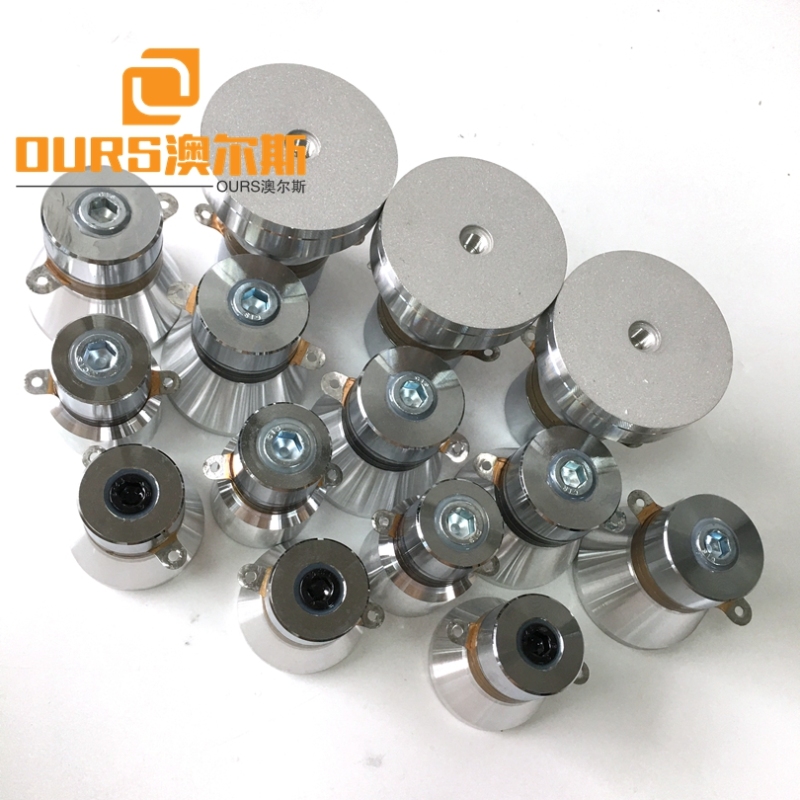

Ultrasonic vibrators have multiple resonance points. Using the second and third resonance points of the vibrator, we have developed dual-frequency ultrasonic vibrators and three-frequency ultrasonic vibrators, which are effective in ultrasonic cleaning machines. The company can customize them according to your needs. Various types of ultrasonic vibrators can achieve a higher level of cleaning effect.

Principle of ultrasonic vibrator arrangement:

(1) Cleaning different product layouts have different requirements, such as the degree of oil staining of the product, the difficulty of cleaning, the level of cleaning requirements, and the design of the cleaning process, all require targeted selection.

(2) The arrangement of the vibrators is not as dense as possible, and the right one is the best.

3. Introduction to ultrasonic vibrator:

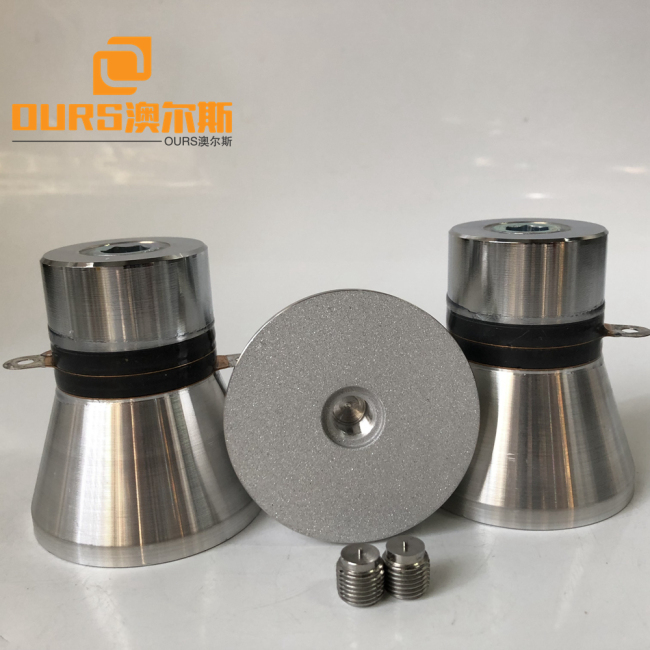

The ultrasonic vibrator, also called the ultrasonic vibrating head, is an ultrasonic transducer and is a core component of the ultrasonic cleaning machine. Industry standard name: Ultrasonic transducer, which belongs to piezoelectric ceramic material and one of the main accessories of ultrasonic cleaning machine. From the power point, a single ultrasonic head is 60W, 100W. The frequencies are: 20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher; the difference in shape is: straight cylindrical shape, horn shape, and the like.

| Specification List | ||||||

| Model | Frequency | Capacitance | Resonance Impedance | Size | Power | Insulation resistance |

| (KHz) | (pF) | (Ω) | Radiation head*Height (mm) | (W) | (2500VDC) | |

| ARS-4QXHNQ-17K60W | 17±0.5 | 4800±10% | ≤25Ω | 78*90 | 60w | ≥100MΩ |

| ARS-4QXHNQ-20K50W | 20±0.5 | 4000±10% | ≤25Ω | 57*94 | 50w | ≥100MΩ |

| ARS-8QXHNQ-20K70W | 20±0.5 | 3250±10% | ≤20Ω | 78*94 | 70w | ≥100MΩ |

| ARS-4QXHNQ-20K100W | 20±0.5 | 7600±10% | ≤20Ω | 67*92 | 100w | ≥100MΩ |

| ARS-8QXHNQ-20K100W | 20±0.5 | 4500±10% | ≤20Ω | 67*92 | 100w | ≥100MΩ |

| ARS-8QXHNQ-20K120W | 20±0.5 | 4650±10% | ≤25Ω | 79*94 | 120w | ≥100MΩ |

| ARS-4QXHNQ-25K60W | 25±0.8 | 4800±10% | ≤20Ω | 59*80 | 60w | ≥100MΩ |

| ARS-4QXHNQ-25K100W | 25±0.5 | 7600±10% | ≤20Ω | 67*76 | 100w | ≥100MΩ |

| ARS-4QXHNQ-28K50WN | 28 ±0.5 | 4000±10% | ≤20Ω | 45*79 | 50w | ≥100MΩ |

| ARS-4QXHNQ-28K60W | 28±0.5 | 4800±10% | ≤20Ω | 59*68 | 60w | ≥100MΩ |

| ARS-4QXHNQ-28K100W | 28±0.5 | 7600±10% | ≤20Ω | 67*68 | 100w | ≥100MΩ |

| ARS-8QXHNQ-28K100W | 28±0.5 | 5800±10% | ≤20Ω | 67*68 | 100w | ≥100MΩ |

| ARS-4QXHNQ-28K120W | 28±0.5 | 9600±10% | ≤20Ω | 67*68 | 120w | ≥100MΩ |

| ARS-8QXHNQ-28K120W | 28±0.5 | 6500±10% | ≤20Ω | 67*68 | 120w | ≥100MΩ |

| ARS-4QXHNQ-33K60W | 33±0.5 | 4800±10% | ≤20Ω | 48*62 | 60w | ≥100MΩ |

| ARS-8QXHNQ-33K60W | 33±0.5 | 3750±10% | ≤20Ω | 48*62 | 60w | ≥100MΩ |

| ARS-4QXHNQ-35K60W | 35±0.5 | 4800±10% | ≤20Ω | 45*55 | 60w | ≥100MΩ |

| ARS-4QXHNQ-40K30W | 40±0.8 | 2400±10% | ≤30Ω | 30*50 | 30w | ≥100MΩ |

| ARS-4QXHNQ-40K50W | 40 ±1.0 | 4000±10% | ≤20Ω | 45*55 | 50w | ≥100MΩ |

| ARS-4QXHNQ-40K50WN | 40 ±1.0 | 4000±10% | ≤20Ω | 45*53 | 50w | ≥100MΩ |

| ARS-8QXHNQ-40K50WN | 40 ±1.0 | 3250±10% | ≤20Ω | 45*53 | 50w | ≥100MΩ |

| ARS-4QXHNQ-40K60W | 40±0.5 | 4800±10% | ≤20Ω | 48*52 | 60w | ≥100MΩ |

| ARS-8QXHNQ-40K60WN | 40±0.5 | 3850±10% | ≤20Ω | 48*50 | 60w | ≥100MΩ |

| ARS-4QXHNQ-40K100W | 40±0.5 | 7600±10% | ≤20Ω | 55*53 | 100w | ≥100MΩ |

| ARS-4QXHNQ-54K35W | 54±1.0 | 3100±10% | ≤35Ω | 30*42 | 35w | ≥100MΩ |

| ARS-4QXHNQ-60K20W | 60±1.5 | 2300±10% | ≤35Ω | 30*35 | 20w | ≥100MΩ |

| ARS-4QXHNQ-65K20W | 65±1.5 | 2300±10% | ≤35Ω | 25*31 | 20w | ≥100MΩ |

| ARS-4QXHNQ-68K50W | 68±2.0 | 4800±10% | ≤20Ω | 50*65 | 50w | ≥100MΩ |

| ARS-4QXHNQ-80K60W | 80±1.5 | 4800±10% | ≤25Ω | 40*54 | 60w | ≥100MΩ |

| ARS-4QXHNQ-100K60W | 100±1.5 | 4800±10% | ≤25Ω | 40*57 | 60w | ≥100MΩ |

| ARS-4QXHNQ-120K60W | 120±1.5 | 4800±10% | ≤25Ω | 40*58 | 60w | ≥100MΩ |

| ARS-4QXHNQ-130K50W | 130±1.5 | 4200±10% | ≤25Ω | 36*54 | 50w | ≥100MΩ |

| ARS-4QXHNQ-160K50W | 160±1.5 | 4800±10% | ≤25Ω | 40*57 | 60w | ≥100MΩ |

| ARS-4QXHNQ-165K40W | 165±5.0 | 4100±10% | ≤60Ω | 42*61 | 40w | ≥100MΩ |

| ARS-4QXHNQ-200K20W | 200±2.0 | 2300±10% | ≤35Ω | 30*35 | 20w | ≥100MΩ |

| ARS-8QXHNQ-28K/40K60W | 28/40±1.0 | 3800±10% | ≤30Ω | 65*70 | 60w | ≥100MΩ |

| ARS-8QXHNQ-40K/130K20W | 40/130±2.0 | 3100±10% | ≤30Ω | 25*58 | 20w | ≥100MΩ |

| ARS-4QXHNQ-40K/68K50W | 38/66±2.0 | 4800±10% | ≤20Ω | 50*65 | 50w | ≥100MΩ |

| ARS-4QXHNQ-40K/80K/130K60W | 40/80/130±2.0 | 4200±10% | ≤25Ω | 40*54 | 60w | ≥100MΩ |

| ARS-4QXHNQ-40/60/8060 | 38/65/84±2.0 | 4800±10% | ≤25Ω | 40*54 | 60w | ≥100MΩ |

| ARS-8QXHNQ-20K/40K/60K120W | 20/40/60±2.0 | 5200±10% | ≤25Ω | 78*94 | 120w | ≥100MΩ |

| ARS-4QXHNQ-38K/100K/160K60W | 38/100/160±2.0 | 4800±10% | ≤25Ω | 40*57 | 60w | ≥100MΩ |

| Screw hole size (diameter * pitch * depth)M10*1.0*10 | ||||||

68KHZ 60W High Frequency Ultrasonic Vibration Sensor For Cleaning Special high - precision Parts

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian