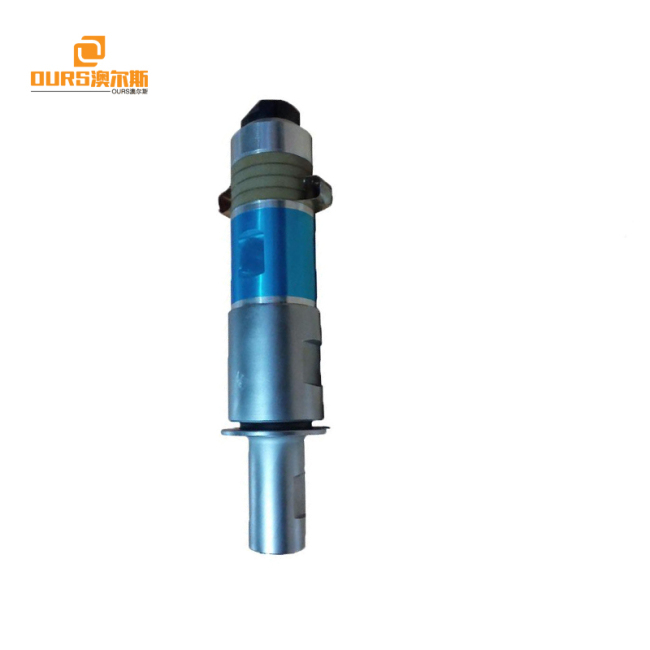

Factory Direct Sales 20KHZ/15KHZ Ultrasonic Welding Vibration Transducer For FFP1/FFP2/FFP3 Ultrasonic Welding

1-499 Piece

$350.00

≥ 500 Piece

$320.00

- Item No.20210314e97bbMOQ1 Piece

- Product size45 x 42 x 40 cmProduct weight10 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Factory Direct Sales 20KHZ/15KHZ Ultrasonic Welding Vibration Transducer For FFP1/FFP2/FFP3 Ultrasonic Welding

When most mask machine manufacturers use aluminum alloys, Lijin mask machines have provided and actively advocated customers to use titanium alloy molds, because it is easy to oxidize and burst compared to aluminum alloys, and is not suitable for long-term operation and use of goods. Shortcomings such as short life, the advantages of titanium alloys are obvious:

A. Good toughness, suitable for long-term vibration;

B. Strong thermal / ultrasonic conductivity, which ensures the welding and cutting effect of the product is beautiful;

C. High hardness, not easy to crack, deform and rust;

D. Although its cost is about ten times that of aluminum alloy, from the perspective of overall production efficiency, the choice of titanium alloy mold is significantly better than aluminum alloy.

2. Imported ultrasonic transducer, 20K international frequency standard, output is more powerful and stable; coupled with two sets of ultrasonic system, effectively guarantee the welding quality of the product.

3.PLC program controls the whole machine to reduce the operation difficulty for users.

Ultrasonic waves are transformed into mechanical vibrations through transducers. The characteristics of transducers depend on material selection and manufacturing process. The performance and service life of transducers of the same size and shape are very different. The commonly used high-power ultrasonic transducer is used in ultrasonic plastic welding machine, ultrasonic metal welding machine, various handheld ultrasonic tools, continuous working ultrasonic emulsifier, atomizer, ultrasonic engraving machine and so on. Commonly used products such as 15KHz 20KHz 28KHz 35KHz 40KHz 55KHz 70KHz can also design and produce non-standard transducers according to the special requirements of customers to meet all kinds of needs.

Our company specializes in producing lace machine welding transducers. This product has high performance, long life and good welding performance. Our company specializes in the development of ultrasonic accessories such as ultrasonic horns, transducers, oscillators, etc. Stable performance, no corrosion, no rust, abrasion resistance, high temperature resistance, stable frequency.

The ultrasonic horn is an important part of the ultrasonic vibration system. Its main role in the vibration system is to amplify the mass displacement or velocity of the mechanical vibration, and to concentrate the ultrasonic energy on a small area, that is, to concentrate energy. Also called an ultrasonic gear shifter or an ultrasonic concentrator. Ultrasonic horns are widely used in chemical, petroleum, plastic welding, metal welding, drilling, turning, cleaning, machining and many other fields.

Ultrasonic horn (ultrasonic horn), as its name suggests, is a functional component that changes the amplitude of ultrasonic vibration in cooperation with an ultrasonic transducer. Its main function is to change the amplitude (generally increase) of the transducer, increase the vibration speed ratio, improve the efficiency, improve the mechanical quality factor, strengthen the heat resistance, expand the adaptable temperature range and extend the life of the transducer. The ultrasonic transducer adjusts the load matching between the transducer and the ultrasonic tool head by installing an horn (ultrasonic horn), reduces the resonance impedance, makes it work at the resonance frequency, improves the electroacoustic conversion efficiency, and is effective Reduce the heat generation of the ultrasonic transducer and increase the service life.

Ultrasonic welding is an industrial technique through which a very high-frequency ultrasonic acoustical vibrations are applied to the work pieces locally and which are being confined together under the influence of high pressure in order to develop a solid-state weld, mostly used for plastics. In other words, it is the joining or altering of thermoplastics via heat which is generated from high-frequency mechanical motion. Electric energy of high frequency is converted into mechanical motion of the same high-frequency to attain welding process. This mechanical motion along with the force which is applied generates frictional heat at the plastic components’ joining surfaces. This will enable the plastic material to melt and form a molecular bond amongst the parts.

Ultrasonic Welding Process

The ultrasonic welder machine will comprise of components such as – Transducer, Sonotrode and Anvil. The complete welding mechanism will include the following steps:

A stationary clamping force is put exactly perpendicular to the interface in between the work pieces.

Then the contacting sonotrode of the welder oscillates parallel to the interface.

This coalesced effect of stationary and oscillating force generates deformation which furthers welding.

| (external sizes) | (electeomachanical characteristic) | ||||||||

| Specification | Connect Screw | Ceramic diameter(mm) | Quantity of Ceramics(pcs) | Resonance Frequency(kHz) | Resistance | Yellow Ceramic | Black Ceramic | Input Power | Max Displacement(um) |

| ARS-6015-4C-Si | M16*1.0 | 60 | 4 | 15 | 15 | 9500-10000 | 12000-12500 | 2200 | 11 |

| ARS-6015-4C-Tr | M16*1.0 | 60 | 8 | 15 | 15 | 19500-20000 | 4200 | 11 | |

| ARS-6015-4C-Qu | M16*1.0 | 38 | 12 | 15 | 15 | 22500-23000 | 27500-28000 | 3200 | 11 |

| ARS-6015-6C-Si | M16*1.0 | 60 | 6 | 15 | 15 | 18500-20500 | 2600 | 11 | |

| ARS-5020-4C-Si | Imperial 3/8 | 50 | 4 | 20 | 15 | 11500-12000 | 13500-14000 | 1500 | 8 |

| ARS-5020-6C-Si | Imperial 3/8 | 50 | 6 | 20 | 15 | 19000-21000 | 2000 | 8 | |

| ARS-5020-4C-Tr | M16*1.0 | 50 | 8 | 20 | 15 | 23000-24000 | 3200 | 8 | |

| ARS-5020-4C-Tr | M16*1.0 | 38 | 8 | 20 | 15 | 17500-18000 | 3200 | 8 | |

| ARS-3828-4C-Si | Imperial 3/8 | 38 | 4 | 28 | 15 | 8000-8500 | 1000 | 5 | |

| ARS-3035-4C-Si | M8.1.25 | 30 | 4 | 35 | 15 | 5200-5600 | 800 | 4 | |

| ARS-3040-4C-Si | M10*1.5 | 30 | 4 | 40 | 15 | 5200-5600 | 800 | 2 | |

Factory Direct Sales 20KHZ/15KHZ Ultrasonic Welding Vibration Transducer For FFP1/FFP2/FFP3 Ultrasonic Welding

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian