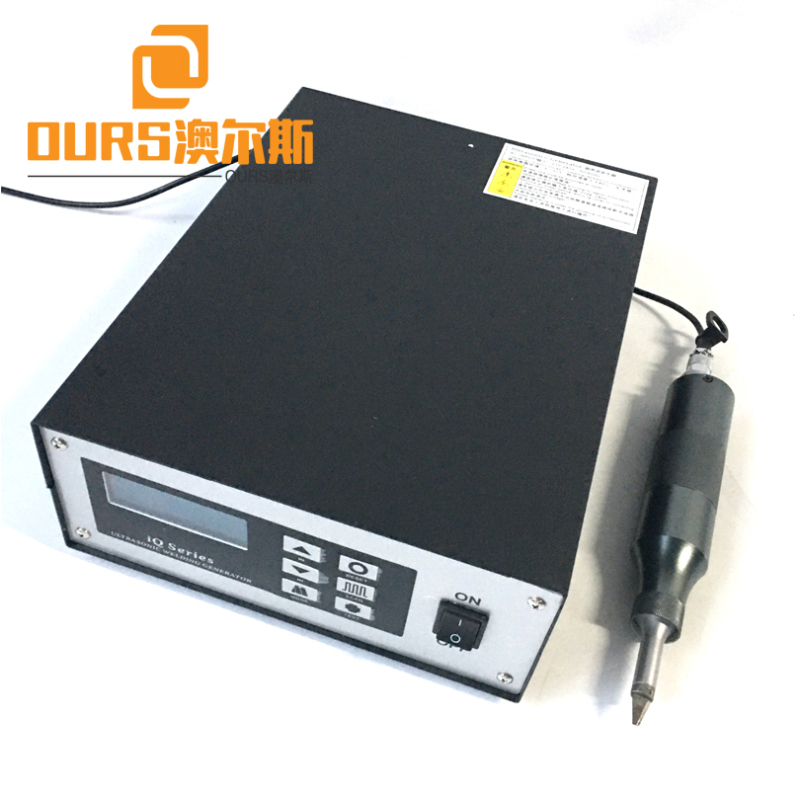

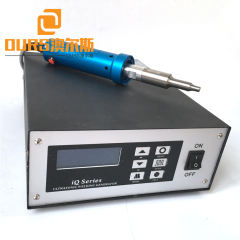

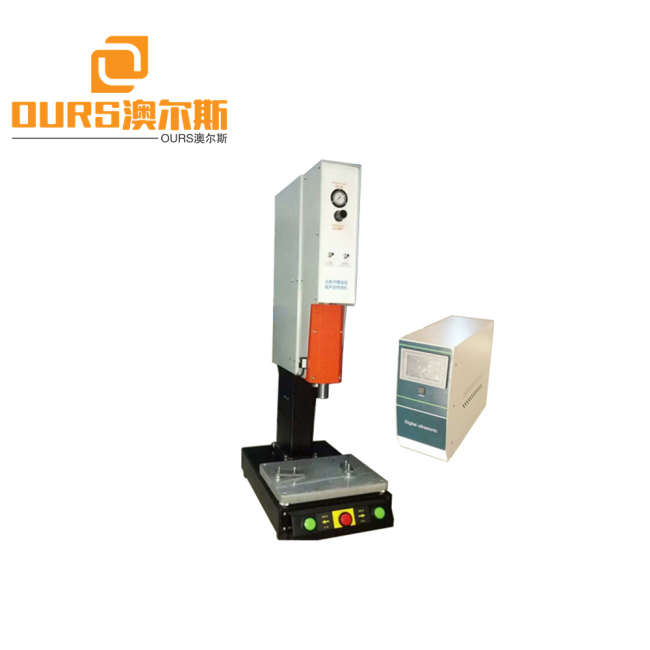

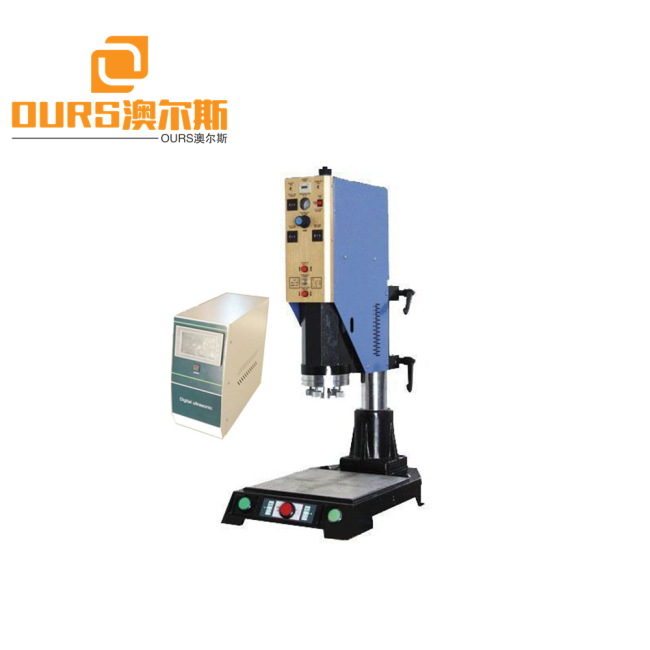

Factory Direct Sales 35khz 800w High Performance Ultrasonic Ribbon Cutting Machine

1-499 Set

$1,750.00

≥ 500 Set

$1,650.00

- Item No.2021020430d5cMOQ1 Set

- Product size48 x 46 x 52 cmProduct weight45 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

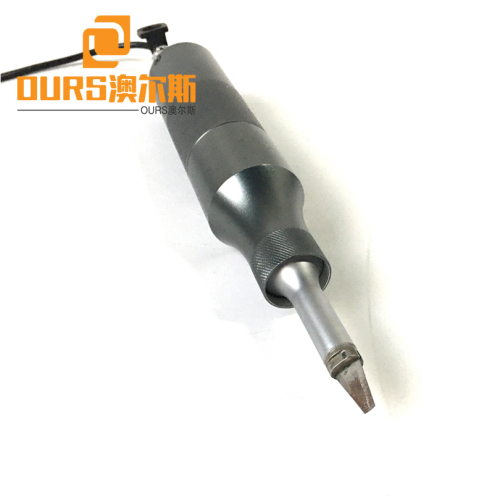

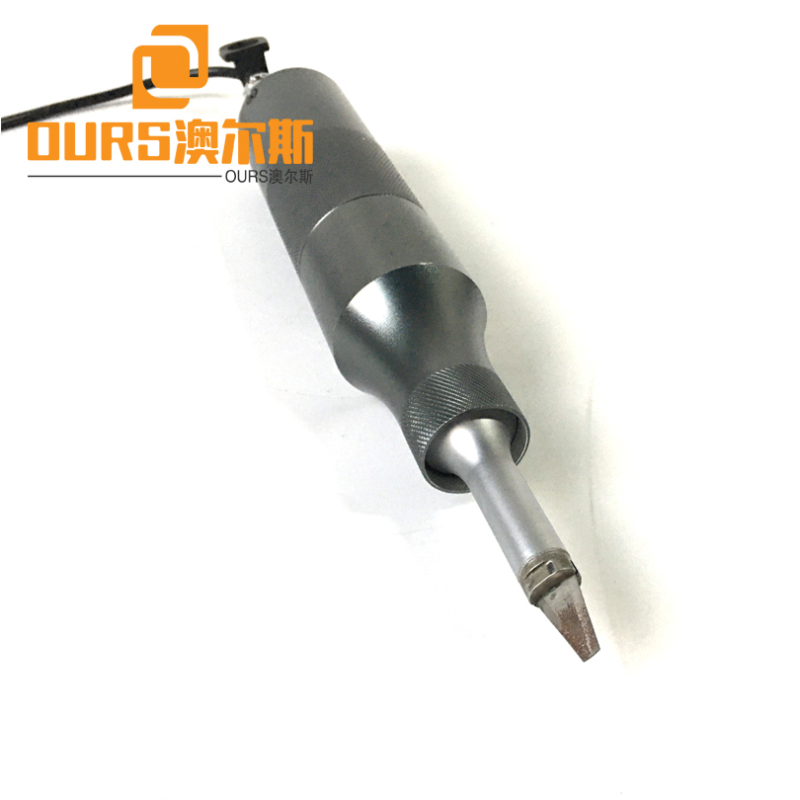

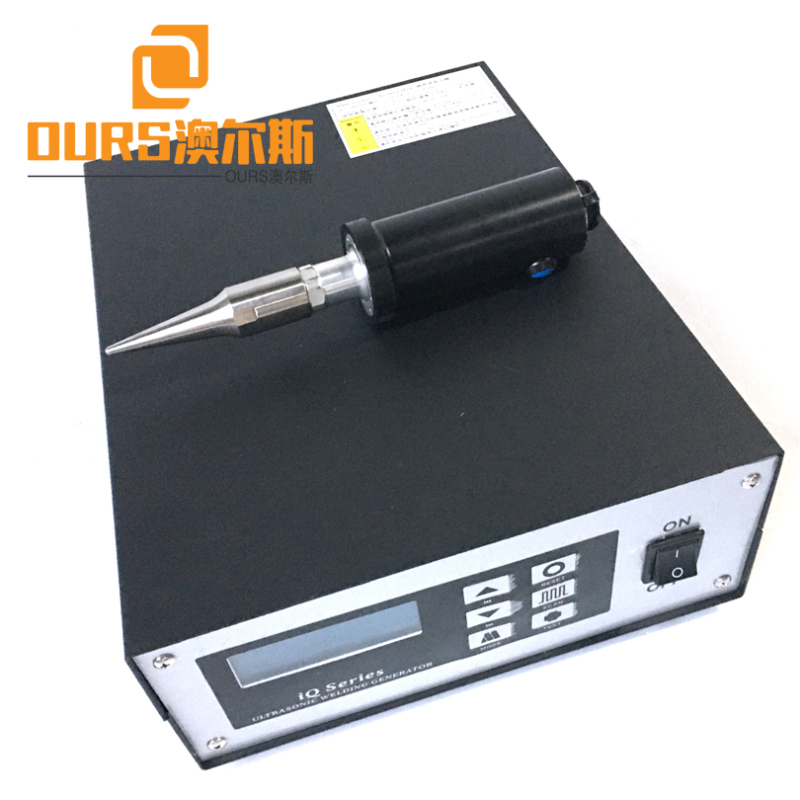

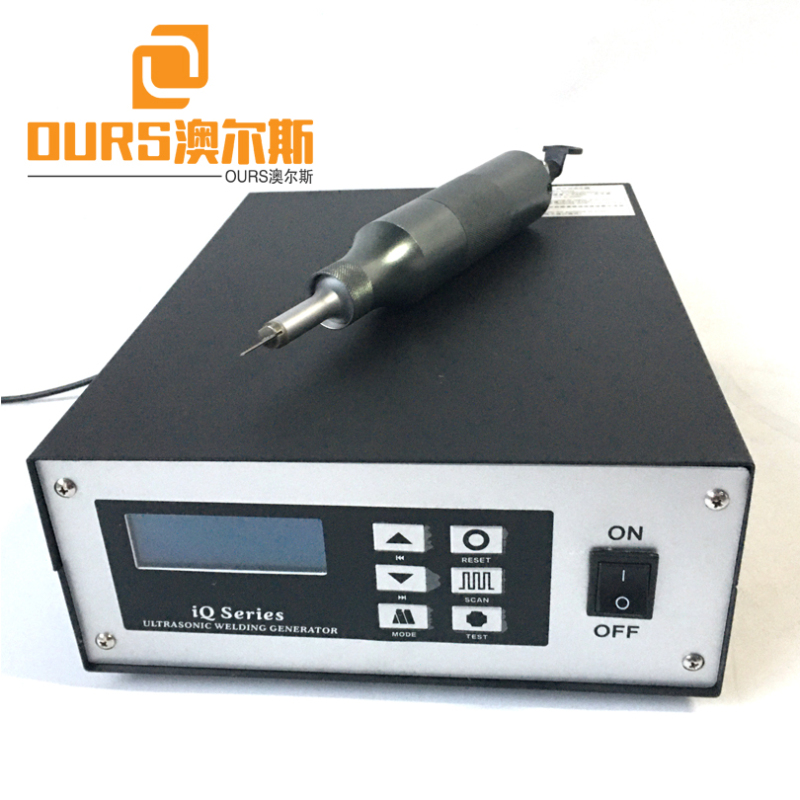

Factory Direct Sales 35khz 800w High Performance Ultrasonic Ribbon Cutting Machine

![]()

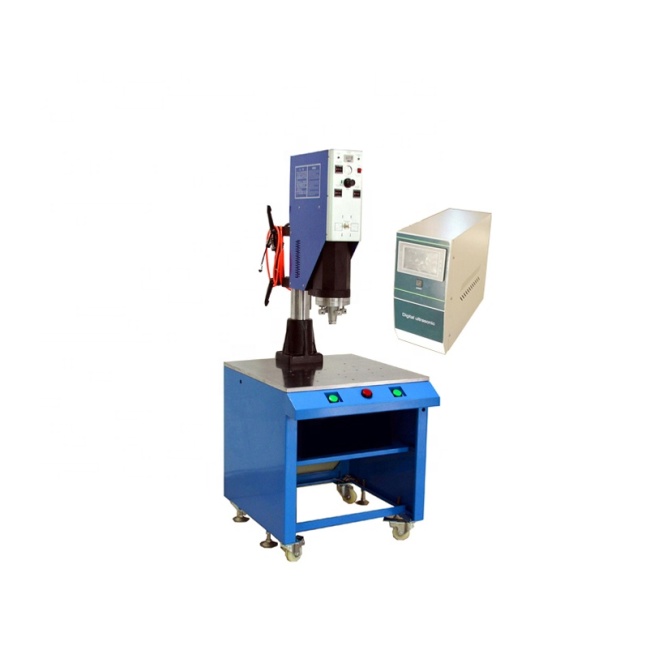

Separate welding

Ultrasound can be used to cut thermoplastic multilayer textiles, non-woven materials or films into arbitrary shapes, and simultaneously weld them along the cutting contour. The thermoplastic fiber content should be at least 20%. The anvil with the corresponding cutting profile is cut by the vibration generated by the ultrasonic system. At the same time, the vibration attenuation causes heat to be generated in the cutting area, thereby welding along the cutting edge.

The cutting blade vibrated by ultrasonic waves quickly and accurately separates the items to be cut with little resistance, and does not produce residue. Ultrasonic has been used for cutting finished products for many years. When cutting baked goods, energy bars, cheese, pizza and other materials, the vibrating (cold) cutting horn can reduce the resistance during the cutting process and remove adhering product residues. The result: a flat surface that can be cut again is formed without deformation or thermal damage to the product.

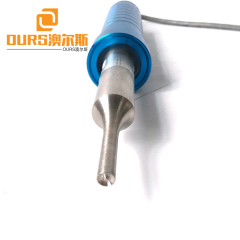

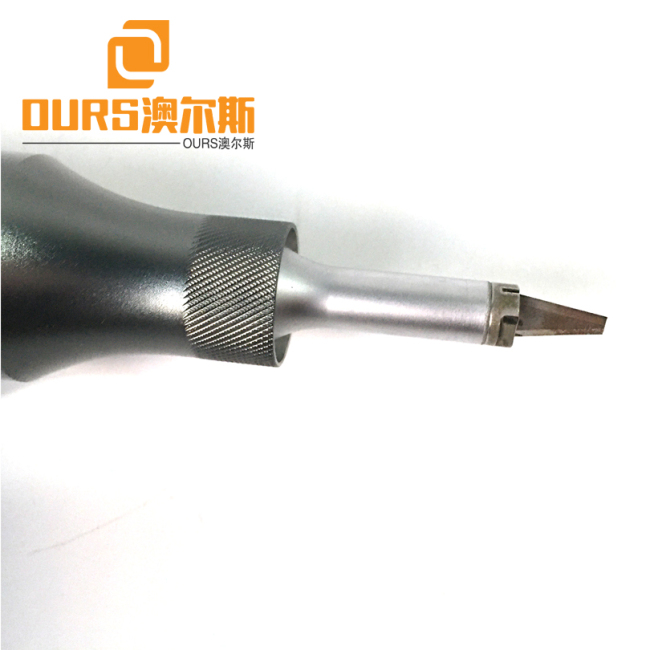

The principle of the ultrasonic rubber cutter is to convert 50/60Hz current into 20, 30 or 40kHz electric energy through an ultrasonic generator. The converted high-frequency electric energy is again converted into mechanical vibration of the same frequency through the transducer, and then the mechanical vibration is transmitted to the cutting knife through a set of amplitude modulator devices that can change the amplitude. The ultrasonic rubber cutting knife vibrates along its length with an amplitude of 10-70μm, repeating 40,000 times (40 kHz) per second (the vibration of the blade is microscopic, which is generally difficult to see with the naked eye). The cutting knife then transfers the received vibration energy to the cutting surface of the workpiece to be cut. In this area, the vibration energy is used to cut the rubber by activating the molecular energy of the rubber and opening the molecular chain.

Advantages of ultrasonic cutting

1. Air-cooled and water-cooled designs can be adopted to adapt to various working conditions and environments

2. The cutting speed is greatly improved, and the efficiency is more than 10 times higher than that of the traditional cutting knife

3. Use high-power ultrasonic transducer as vibrating element to ensure long-term stable work

4. The variety of cutting tools is complete, and cutting tools with relevant shapes can also be customized according to customer processes

5. It can cut all kinds of products that are difficult to cut by ordinary tools, and solve the production and processing problems

6. High hardness blades can be installed, and the cutting blades can be replaced, which reduces the cost of use

7. Easy to install and use, hardly changing the original cutting process

8. High cutting precision, good cut surface finish

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-50015 | 500W | 15KHz |

ARS-DHJ-50020 | 500W | 20KHz |

ARS-DHJ-90015 | 900W | 15KHz |

ARS-DHJ-90020 | 900W | 20KHz |

ARS-DHJ-150015 | 1500W | 15KHz |

ARS-DHJ-150020 | 1500W | 20khz |

ARS-DHJ-200015 | 2000W | 15KHz |

ARS-DHJ-200020 | 2000W | 20khz |

![]()

Factory Direct Sales 35khz 800w High Performance Ultrasonic Ribbon Cutting Machine

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian