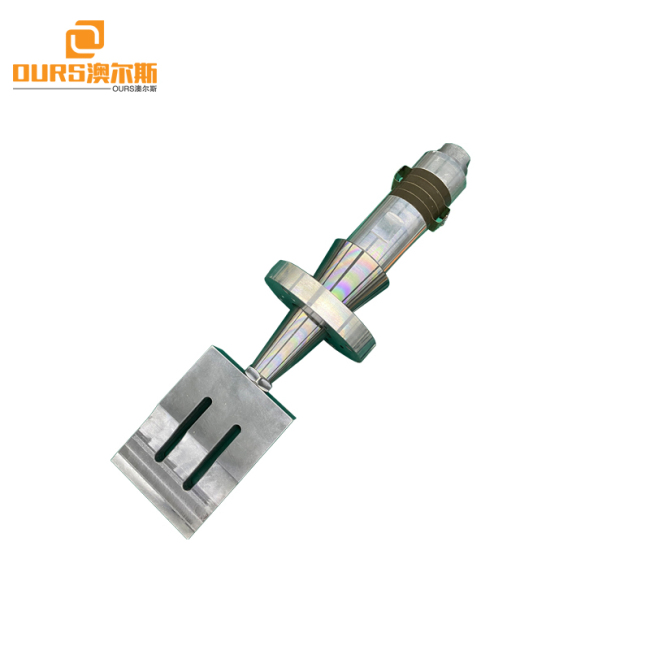

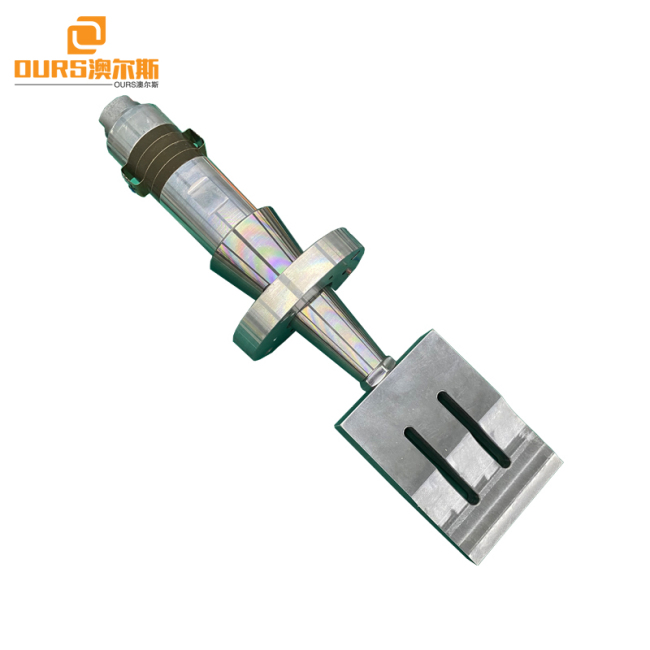

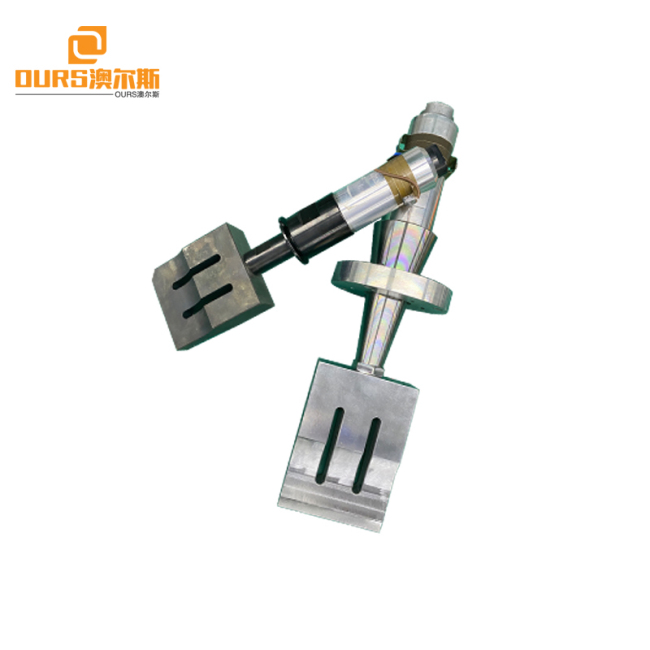

High Amplitude 2600w Ultrasonic Welding Converter 15khz For Assembly Ultrasonic Welding Plastic Machine

≥1 Unit

$300.00

- Item No.OURS-6015-4C-SiMOQ1 Unit

- Product size40 x 20 x 20 cmProduct weight8 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

The ultrasonic transducer conducts ultrasonic waves to the plastic processing parts through the welding head, so that the two plastic joints are subjected to ultrasonic waves to produce violent friction, and the friction heat melts the plastic joints to complete the gluing. This technology has the advantages of fast speed and firm welding seams, and more importantly, it can automate the production and processing of plastic products. Ultrasonic plastic welding machine can perform plastic welding, embedding, forming, riveting, spot welding, cutting, sewing and other operations. As long as the welding head is changed, one machine can be used for multiple applications.

Our company specializes in the production of ultrasonic welding transducers. This product has high performance, long life, and good welding effect. The ultrasonic used in plastic processing, the existing working frequencies are 15KHZ, 18KHZ, 20KHZ, 40KHZ. The principle is to use the peak position of the longitudinal wave to transmit the amplitude to the gap of the plastic part. Under pressure, the two plastics The molecules in the contact parts of the parts or other parts and the plastic parts collide with each other to melt, so that the plastic in the contact position is fused to achieve the processing purpose.

Ultrasonic welding transducer for the ultrasonic processing of thermoplastic glue uses the high-frequency friction between the working joints to rapidly generate heat between molecules. When this heat is enough to melt the work, the ultrasonic vibration is stopped. The surface is melted and solidified, completing the processing procedure. The frequencies usually used for plastic processing are 20KHZ and 15KHZ, and their frequencies are outside of human hearing, so they are called ultrasonic waves. Ultrasonic welding machines should be used in the electronics industry, stationery industry, transportation equipment, toys, cosmetics, motors and other materials such as PP, PE, ABS, and acrylic.

| (external sizes) | (electeomachanical characteristic) | ||||||||

| Specification | Connect Screw | Ceramic diameter (mm) | Quantity of Ceramics (pcs) | Resonance Frequency (kHz) | Resistance | Yellow Ceramic | Black Ceramic | Input Power | Max Displacement (um) |

| OURS-6015-4C-Si | M16*1.0 | 60 | 4 | 15 | 15 | 9500-10000 | 12000-12500 | 2200 | 11 |

| OURS-6015-4C-Tr | M16*1.0 | 60 | 8 | 15 | 15 | 19500-20000 | 4200 | 11 | |

| OURS-6015-4C-Qu | M16*1.0 | 38 | 12 | 15 | 15 | 22500-23000 | 27500-28000 | 3200 | 11 |

| OURS-6015-6C-Si | M16*1.0 | 60 | 6 | 15 | 15 | 18500-20500 | 2600 | 11 | |

| OURS-5020-4C-Si | BS 3/8 | 50 | 4 | 20 | 15 | 11500-12000 | 13500-14000 | 1500 | 8 |

| OURS-5020-6C-Si | BS 3/8 | 50 | 6 | 20 | 15 | 19000-21000 | 2000 | 8 | |

| OURS-5020-4C-Tr | M16*1.0 | 50 | 8 | 20 | 15 | 23000-24000 | 3200 | 8 | |

| OURS-5020-4C-Tr | M16*1.0 | 38 | 8 | 20 | 15 | 17500-18000 | 3200 | 8 | |

| OURS-3828-4C-Si | BS 3/8 | 38 | 4 | 28 | 15 | 8000-8500 | 1000 | 5 | |

| OURS-3035-4C-Si | M8.1.25 | 30 | 4 | 35 | 15 | 5200-5600 | 800 | 4 | |

| OURS-3040-4C-Si | M10*1.5 | 30 | 4 | 40 | 15 | 5200-5600 | 800 | 2 | |

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian