Manufacturers Supply 28KHZ 800W Digital Ultrasonic Textile Cutting Machine

1-499 Set

$1,750.00

≥ 500 Set

$1,650.00

- Item No.2021020449779MOQ1 Set

- Product size48 x 46 x 52 cmProduct weight45 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Manufacturers Supply 28KHZ 800W Digital Ultrasonic Textile Cutting Machine

![]()

Traditional cutting uses a knife with a sharp edge to press against the material to be cut. The pressure is concentrated at the cutting edge, and the pressure is very large, exceeding the shear strength of the material being cut, and the molecular bonds of the material are pulled apart and cut. Since the material is pulled apart by strong pressure and rigidity, the cutting edge of the cutting tool should be very sharp, and the material itself has to bear relatively large pressure. The cutting effect is not good for soft and elastic materials, and it is more difficult for sticky materials.

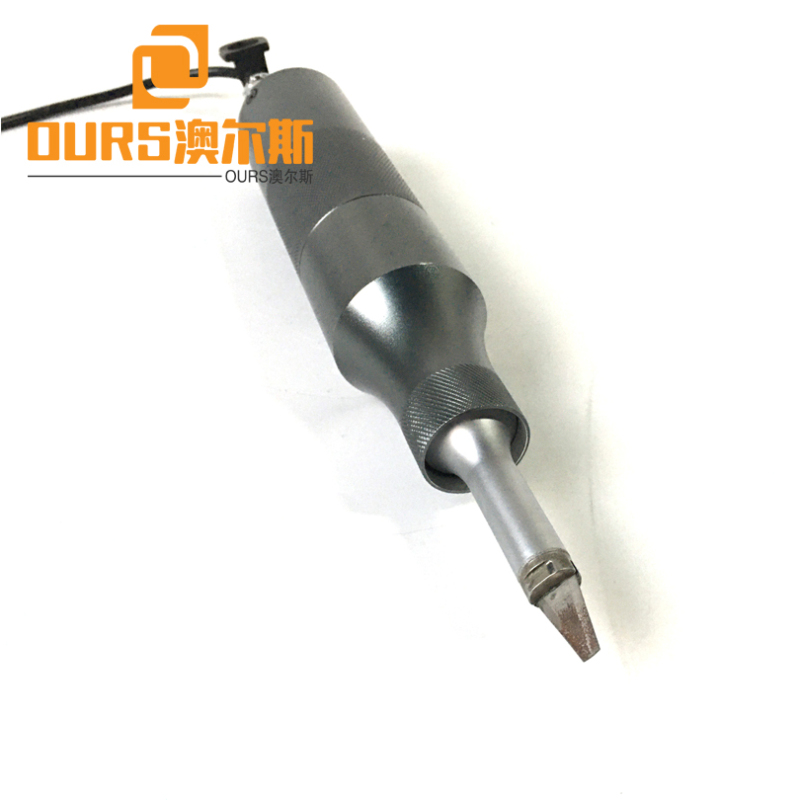

The basic structure of the ultrasonic cutting machine. Ultrasonic transducer, ultrasonic horn, ultrasonic cutting knife, ultrasonic generator.

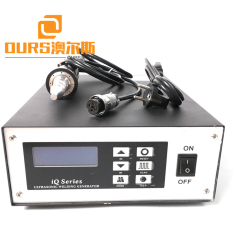

Ultrasonic generator

The mains electricity is converted into high frequency and high voltage alternating current, which is output to the ultrasonic transducer. Ultrasonic transducer is equivalent to energy conversion device, it can convert the input electric energy into mechanical energy, namely ultrasonic. The ultrasonic transducer stretches back and forth in the longitudinal direction, and the frequency of the stretch movement is equal to the frequency of the high-frequency alternating current supplied by the driving power source.

Ultrasonic Horn

The ultrasonic horn amplifies the output amplitude of the ultrasonic transducer.

Ultrasonic cutter

Amplify the amplitude further and focus the ultrasound.

Ultrasonic wave is output, and the cutting knife is used to concentrate the ultrasonic energy into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, this part instantly softens and melts, and its strength drops greatly. Only a small amount of force is required to achieve the purpose of cutting materials.

The knife-type cutting machine loads ultrasonic waves on the cutting knives, so that the knives generate ultrasonic vibration, thereby achieving the cutting effect.

This cutting method is suitable for: raw rubber slitting, tube cutting, frozen meat, candy, chocolate cutting, printed circuit boards, natural fiber division, synthetic fiber deep digging, plastic shell processing, artificial resin coating, hand-held cutting, etc.

Chopping board

The anvil-type cutting machine loads the ultrasonic vibration on the cutting bottom mold. This bottom mold is like the cutting board used in life. The cutting board generates ultrasonic vibration, which can also achieve the cutting effect, and the cutting tool does not need to be changed. Ordinary tools are fine.

Advantages of ultrasonic cutting

1. Air-cooled and water-cooled designs can be adopted to adapt to various working conditions and environments

2. The cutting speed is greatly improved, and the efficiency is more than 10 times higher than that of the traditional cutting knife

3. Use high-power ultrasonic transducer as vibrating element to ensure long-term stable work

4. The variety of cutting tools is complete, and cutting tools with relevant shapes can also be customized according to customer processes

5. It can cut all kinds of products that are difficult to cut by ordinary tools, and solve the production and processing problems

6. High hardness blades can be installed, and the cutting blades can be replaced, which reduces the cost of use

7. Easy to install and use, hardly changing the original cutting process

8. High cutting precision, good cut surface finish

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-50015 | 500W | 15KHz |

ARS-DHJ-50020 | 500W | 20KHz |

ARS-DHJ-90015 | 900W | 15KHz |

ARS-DHJ-90020 | 900W | 20KHz |

ARS-DHJ-150015 | 1500W | 15KHz |

ARS-DHJ-150020 | 1500W | 20khz |

ARS-DHJ-200015 | 2000W | 15KHz |

ARS-DHJ-200020 | 2000W | 20khz |

![]()

Manufacturers Supply 28KHZ 800W Digital Ultrasonic Textile Cutting Machine

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian