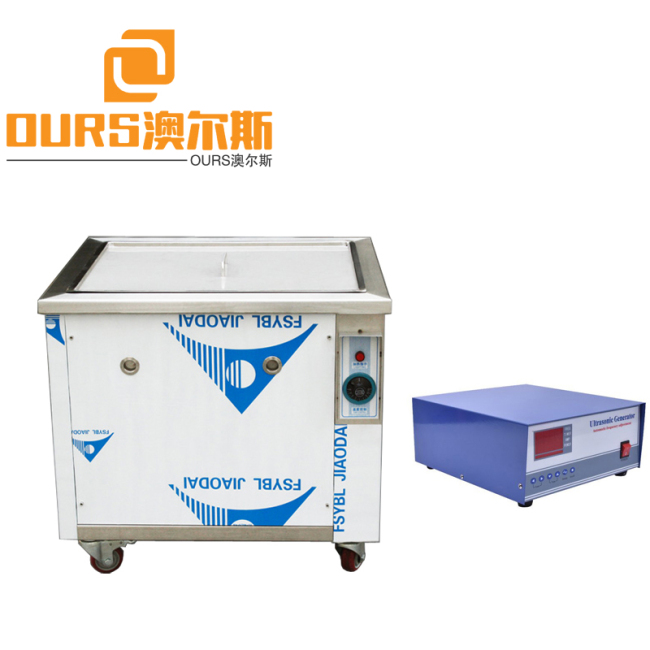

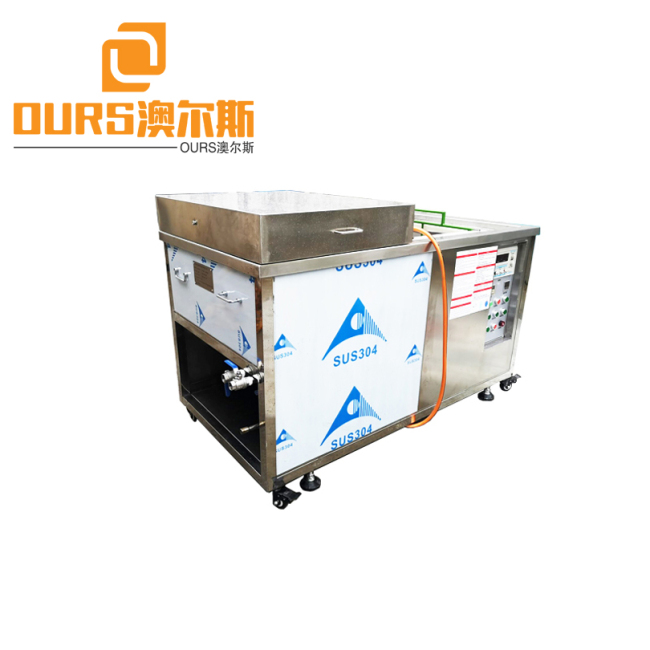

Plastic Mold-Ultrasonic Cleaning Equipment 28Khz 3500W For Electrolytic Cleaning Of Copper Casting Mold

1-9 Piece

$8,500.00

≥ 10 Piece

$8,200.00

- Item No.2021072465dd4MOQ1 Piece

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Principle of electrolytic mold cleaning machine: electrolysis is the process of chemical decomposition of substances under the action of electric current. During the electrolysis process, the dirt on the metal surface begins to fall off, and the peeling is accelerated under the impact of ultrasonic waves. The metal surface is stained with animal and vegetable oils, minerals Oil, paraffin, carbon deposit, oxide layer. Use electrolysis to remove these dirt. When the current passes through the mold electrolytic cleaning agent containing a special formula, oxygen is generated near the positive electrode of the electrolytic cell, and hydrogen is generated at the negative electrode. Put the metal parts to be cleaned into the positive electrode of the electrolytic cell, and there will be fines on the metal surface during the electrolysis process. The hydrogen gas is produced, and these small bubbles promote the peeling of the dirt from the metal surface. Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to convert the transducer from electrical energy to mechanical energy. During this process, the transducer transfers huge energy to the cleaning tank solution. , Generate positive and negative pressure zones in the liquid, forming tens of thousands of cavitation bubbles, which continue to form explosions, impact the surface of the cleaned metal object, and quickly release the dirt on the metal surface. To clean the mold and restore the mold True color.

Advantages of mold ultrasonic cleaning machine:

1. The electrolytic cleaning system emits gas to the metal surface, and uses the sauna cleaning effect to remove the dirt, impurities, and sundries on the metal surface. It can also completely remove resin components and moisture; through ultrasonic vibration, the dirt peels off and floats, and the metal is attached to the cathode. Even the dirt in the dead corner can be completely removed.

2. Restore the metal to the original copper-green color and restore the original beauty of the metal.

3. Even complex shapes can remove dirt.

4. It can achieve the purpose of cleaning and decontamination.

5. It has a good rust removal and antirust effect.

6. Generally speaking, it takes about an hour to save time than manual cleaning.

7. It is more environmentally friendly and safer than using organic solvents.

8. It can greatly reduce the defective rate after washing.

9. This cleaning machine has a long service life, generally at least five years.

10. The purchase cost and use cost of the whole machine are relatively reasonable.

- Technical process: electrolytic cleaning → washing with city water → anti-rust

- Main components: ultrasonic generating system, electrolytic circuit system, circulating filter system

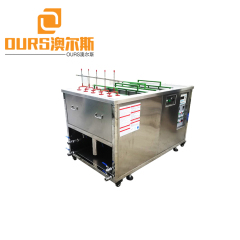

Working principle: Use the mold or the workpiece to be cleaned as the cathode (just put it in the cleaning frame), and use the standard electrode rod as the anode. - The use of electrolyzed water produces oxygen at the anode and hydrogen at the cathode. During the operation process, a large amount of hydrogen is generated on the surface of the workpiece, so that the dirt is quickly decomposed and peeled off from the surface of the workpiece; at the same time, the cavitation effect of ultrasonic waves is used to cause countless small bubbles to collide with the object. Impact blasting the dirt on the workpiece to automatically peel off the dirt.

At the same time, the special cleaning liquid 102C is used to make the dirt decompose rapidly through a sufficient chemical reaction. In this way, even the difficult-to-clean parts, such as the grooves, grooves, corners, holes, holes, bites and other complicated parts inside the mold, will be cleaned cleanly, and the mold will show a brilliant metallic luster from the inside to the outside.

The cleaned molds are rinsed with water, and then soaked with special water-based rust inhibitor for steel. This anti-rust agent can quickly remove the moisture on the surface of the mold and form a protection on the surface of the mold. After air-drying, it can be stored or reprocessed. Re-production will not produce carbides attached to the mold. - Scope of application: plastic molds, hardware molds, optical mirror molds, rubber molds, medical equipment, auto parts molds, etc.

Note: Various non-standard models and sizes can be customized according to customer requirements.

The plastic mold-ultrasonic cleaning machine independently developed by the company has been recognized by Japanese, Korean, Taiwanese, and Hong Kong-owned factories, breaking the monopoly of foreign imports; it has mastered a series of plastic, rubber, silicone, and acetate. , The cleaning process of bakelite molds can effectively and thoroughly remove residual high-temperature oxides on the molds; rust spots and oil residues; plastic mold cleaning machines rank first in the industry.

Equipment use: used for cleaning plastic molds, modules, modules, mold cores, inserts, inserts, removing high-temperature carbon deposits, removing sulfides, gas, degreasing, and rust removal.

Type | Frequency (Khz) | Power(W) | Capacity(L) |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1500 | 30 |

ARS-MJQXJ-50LTT | 28KHZ,40KHZ | 2500 | 50 |

ARS-MJQXJ-70LTT | 28KHZ,40KHZ | 3500 | 70 |

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian