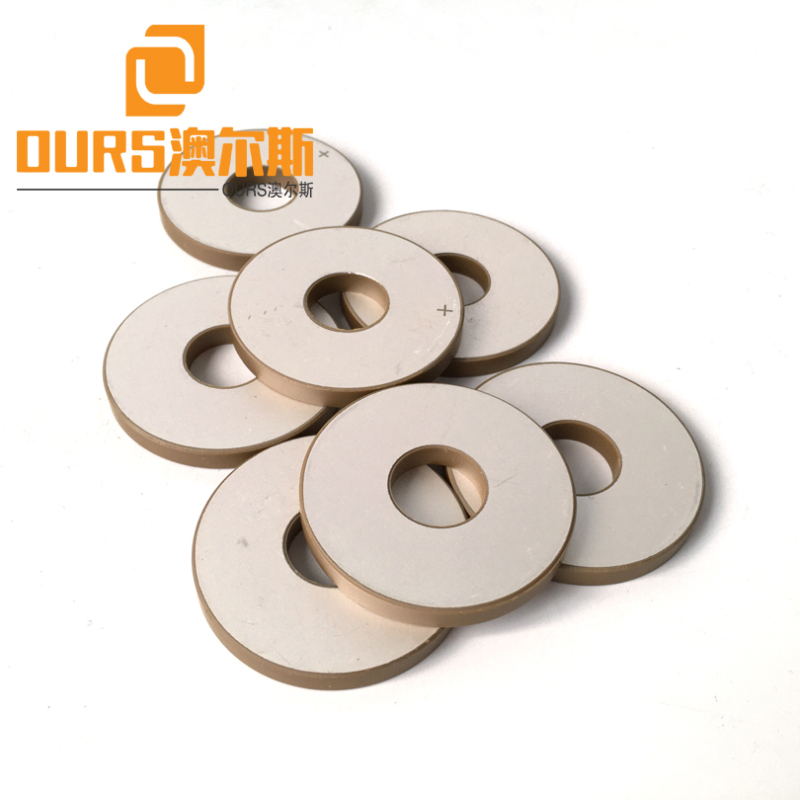

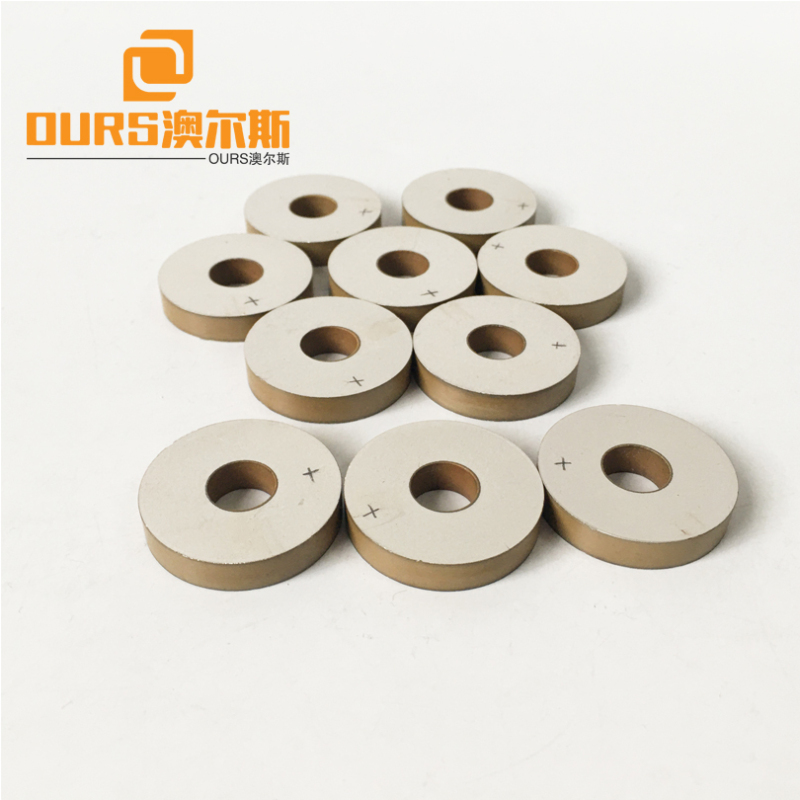

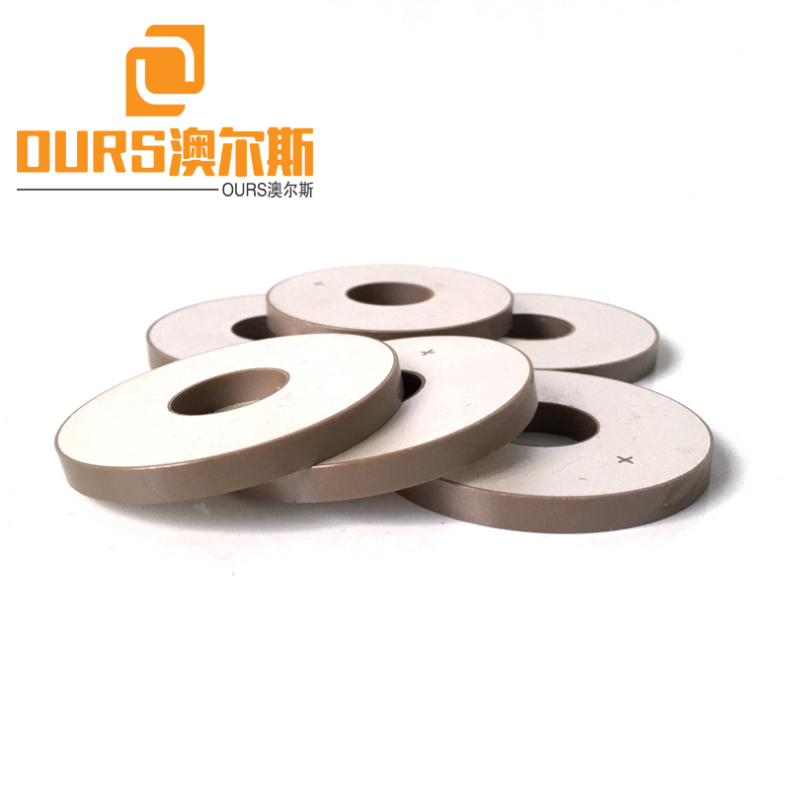

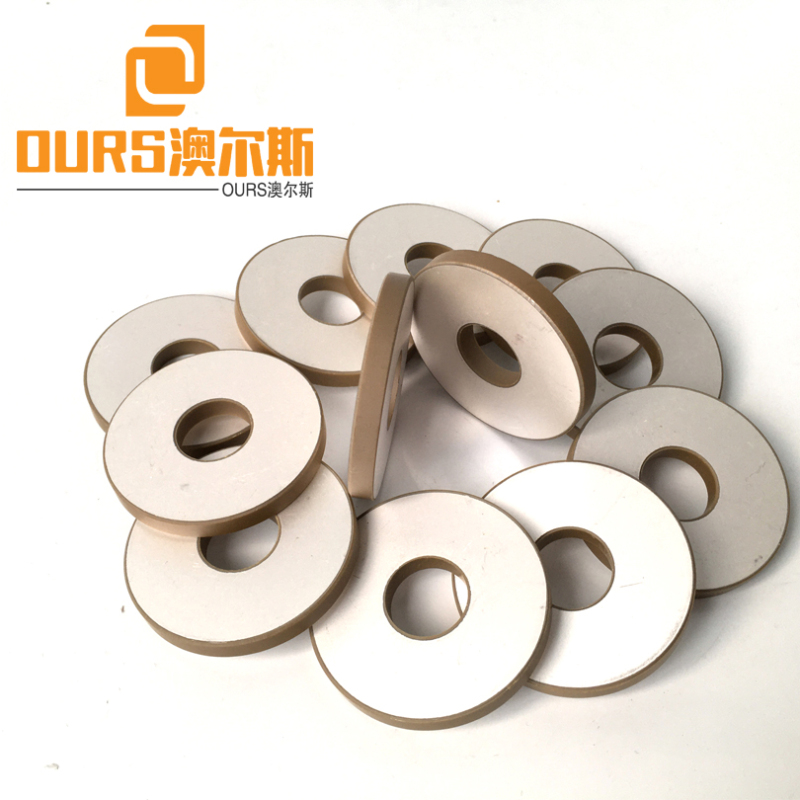

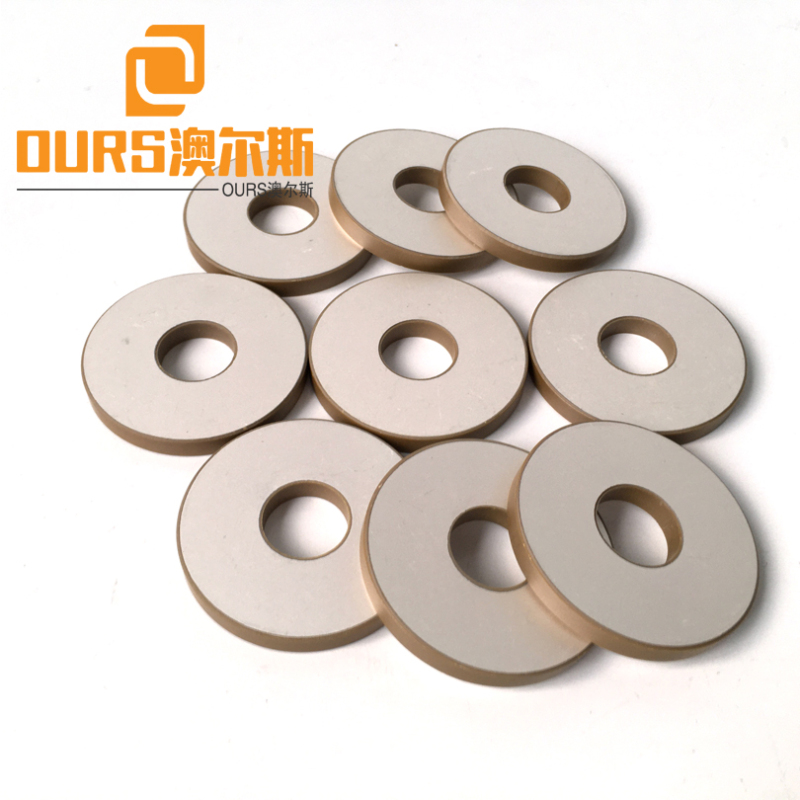

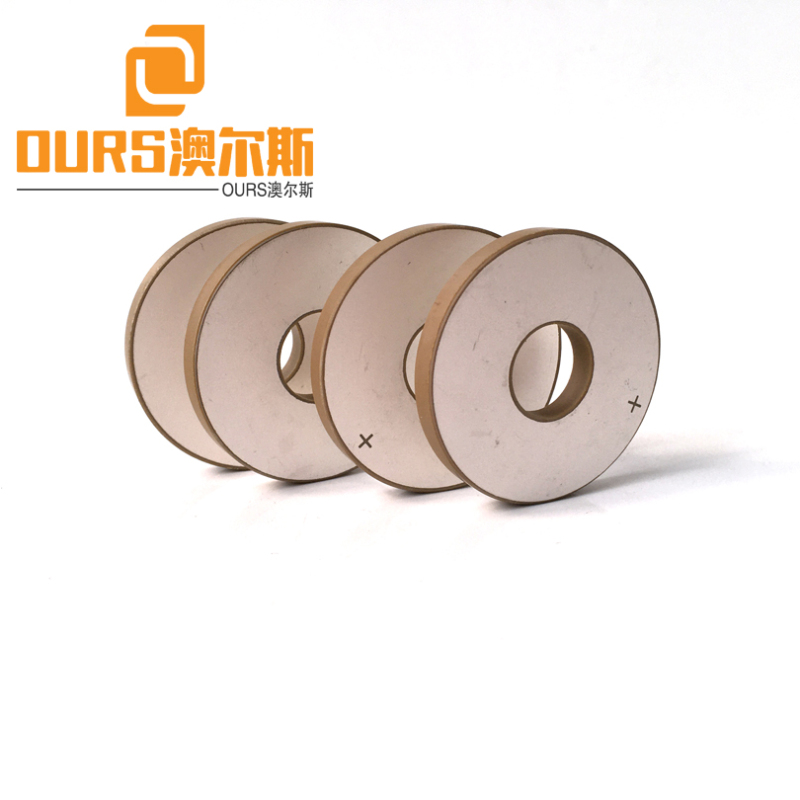

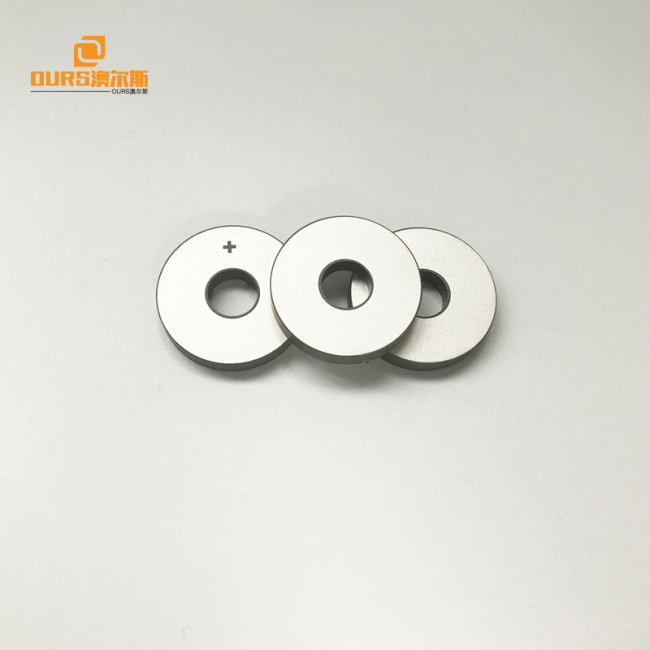

Ring Piezo Ceramic 35X15X5mm PZT4 or PZT8 For Ultrasonic Cleaning /Transducer

50-9999 Piece

$4.50

≥ 10000 Piece

$3.50

- Item No.ARS-JHJP35155MOQ50 Piece

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

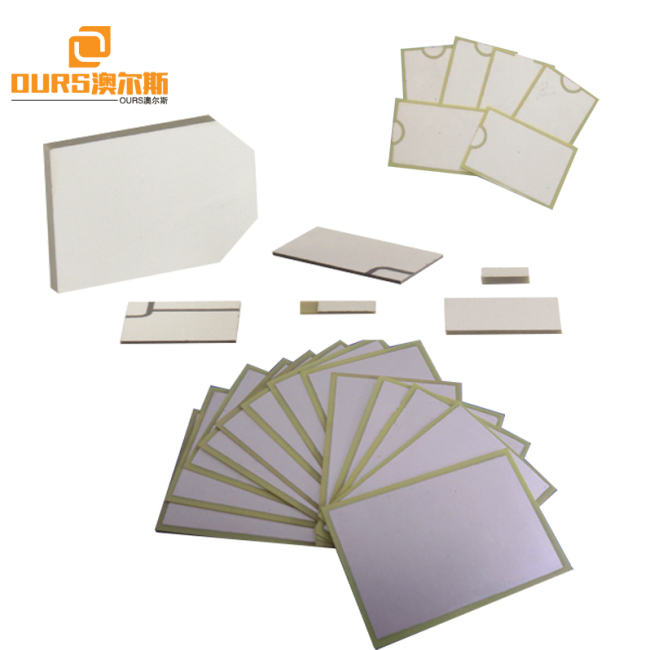

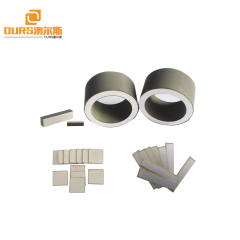

Ring Piezo Ceramic 35X15X5mm PZT4 or PZT8 For Ultrasonic Cleaning /Transducer  Piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

Piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

PiezoelectricCeramics (PZT) materials are categorized as functional ceramics. In sensors they make it possible toconvert forces, pressures and accelerations into electrical signals, and in sonic and ultrasonic transducers and actuators they convert electric voltages into vibrations or deformations.PiezoelectricCeramics materials are classified according to their chemical composition on the one hand, and by the specific application conditions on the other.

Piezoelectric ceramics is a kind of information functional ceramic material that can convert mechanical energy and electrical energy to each other-piezoelectric effect. In addition to piezoelectricity, piezoelectric ceramics also have dielectric properties and elasticity. Acoustic sensors, acoustic transducers, ultrasonic motors, etc. Piezoelectric ceramics are made by using their materials to cause relative displacement of the positive and negative charge centers inside the material under the action of mechanical stress, resulting in polarization, resulting in the opposite signs of bound charges appearing on both ends of the material, that is, the piezoelectric effect. It has sensitive characteristics. Ceramics are mainly used to manufacture ultrasonic transducers, underwater acoustic transducers, electroacoustic transducers, ceramic filters, ceramic transformers, ceramic discriminators, high-voltage generators, infrared detectors, surface acoustic wave devices, electro-optical devices, In addition to being used in high-tech fields, ignition and detonation devices and piezoelectric gyros are used to serve people in daily life and work hard to create a better life for people.

Electronic ceramics Ceramics that can use electrical and magnetic properties in the electronics industry are called electronic ceramics. Electronic ceramics finally obtain ceramics with new functions through precise control of the surface, grain boundaries and dimensional structure. It can be widely used in energy, household appliances, automobiles, etc.

The development of electronic ceramic materials is closely related to the development of physical chemistry, applied physics, silicate physical chemistry, solid-state physics, optics, electricity, acoustics, radio electronics, etc., and they promote each other, thus making a leap in the development of electronic technology. In China, electronic ceramics have also made great progress accordingly.

Electronic ceramics can be divided into five categories according to their functions and uses: insulating ceramics, capacitor ceramics, ferroelectric ceramics, semiconductor ceramics and ion ceramics.

Application of special sensitive ceramic automotive sensors

Electronic ceramic sensors for automobiles are required to be suitable for a long time in the harsh environment of automobiles (high temperature, low temperature, vibration, acceleration, humidity, sound, exhaust gas), and they should have the characteristics of small and light weight, good reusability, and wide output range. Ceramic heat-resistance, corrosion-resistance, wear-resistance and its potential excellent electromagnetic and optical functions have been fully utilized in recent years with the advancement of manufacturing technology. Sensors made of sensitive ceramic materials can fully meet the above requirements.

Application of ceramic materials in automobile spraying technology

In recent years, aerospace technology has been widely used in ceramic film spraying technology and began to be applied to automobiles. The advantages of this technology are good thermal effect, can withstand high temperature and pressure, mature technology, and stable quality. In order to achieve the goal of low heat dissipation, ceramic spraying can be applied to the engine combustion chamber components, such as zirconia spray on the top of the piston and zirconia spray on the cylinder liner. After this treatment, the engine can reduce heat loss, reduce the quality of the engine itself, reduce the size of the engine, and reduce fuel consumption.

Application of Alumina Ceramic Automobile Shock Absorber

The high-end car vibration damping device has successfully developed an intelligent shock absorber by comprehensively using the positive piezoelectric effect of sensitive ceramics and the electrostrictive effect of the inverse piezoelectric effect of alumina ceramics. Due to the use of high-sensitivity ceramic components, this type of shock absorber has the function of identifying the road surface and can do self-adjustment, which can minimize the vibration of the car due to the rough road surface.

Application

1. ultrasonic cleaning trasnducer

2. ultrasonic welding tansducer

3. ultrasonic beauty transducer

4. ultrasonic underwater transducer

5. ultrasonic immersible transucer

6. ultrasonic screening transducer

7. ultrasonic cutting transducer

8. ultrasonic atomization transducer

9. ultrasonic emulsifier

![]()

Ring Piezo Ceramic 35X15X5mm PZT4 or PZT8 For Ultrasonic Cleaning /Transducer

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian