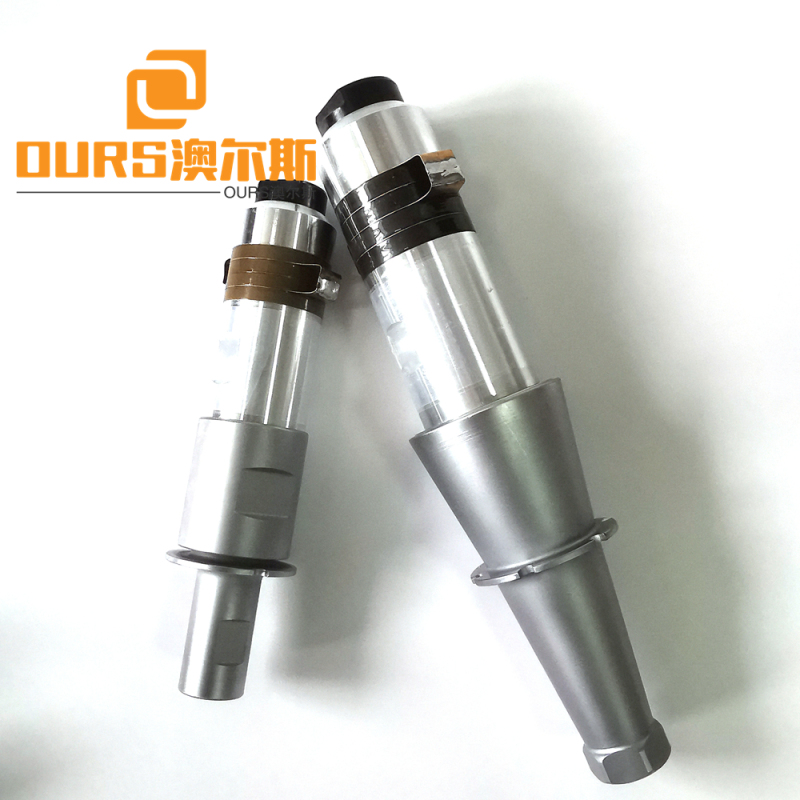

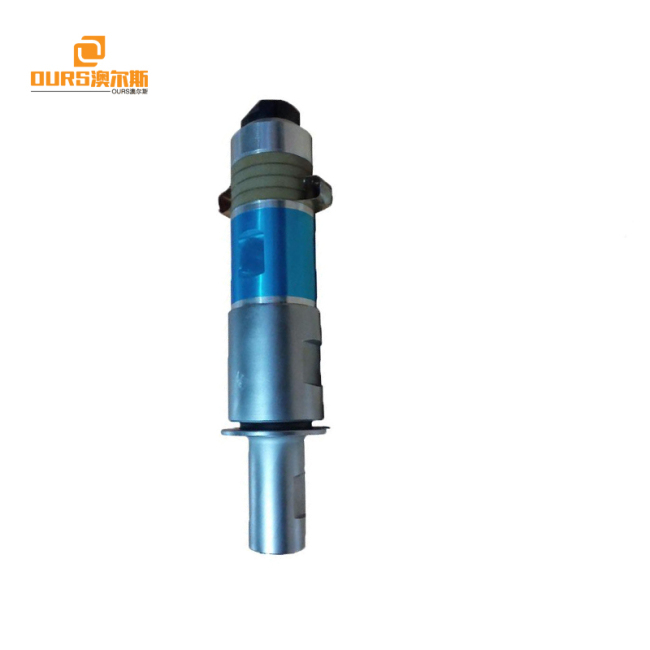

Ultrasound 15khz Ultrasonic Welding Transducer 2600w Ultrasonic Cutting Transducer

≥1 Unit

$250.00

- Item No.OURS-6015-4C-SiMOQ1 Unit

- Product size40 x 20 x 20 cmProduct weight10 kg

Choice

Online customization Customise Now

Customized logo (Min. Order: 1 Unit)

Customized packaging (Min. Order: 1 Unit)

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Ultrasonic plastic welding transducer is to conduct ultrasonic waves to the plastic processing parts through the welding head, so that the two plastic joint surfaces are subjected to ultrasonic waves to produce violent friction, and the friction heat melts the plastic joint surfaces to complete the gluing. This technology has the advantages of fast speed and firm welding seams, and more importantly, it can automate the production and processing of plastic products. Ultrasonic plastic welding machine can perform plastic welding, embedding, forming, riveting, spot welding, cutting, sewing and other operations. As long as the welding head is changed, one machine can be used for multiple applications.

Main Features of Ultrasonic Welding Transducer:

1. High mechanical quality

2. Piezoelectric element offer a high speed of vibration.

3. Having steady output amplitude even the load markedly changed.

4. Extended using temperature, ensuring good amplitude linearity

5. Bolt-on mounting gives the fast, easy installation and high reliability.

6.easy for assembling

7. good heat resistance

8. large range of working temperature

9.low resonance impedance and heat productivity

10.good construction

11.fastened by bolt

| (external sizes) | (electeomachanical characteristic) | ||||||||

| Specification | Connect Screw | (mm)Ceramic diameter | (pcs)Quantity of Ceramics | (kHz)Resonance Frequency | Resistance | Yellow Ceramic | Black Ceramic | Input Power | (um)Max Displacement |

| OURS-6015-4C-Si | M16*1.0 | 60 | 4 | 15 | 15 | 9500-10000 | 12000-12500 | 2200 | 11 |

| OURS-6015-4C-Tr | M16*1.0 | 60 | 8 | 15 | 15 | 19500-20000 | 4200 | 11 | |

| OURS-6015-4C-Qu | M16*1.0 | 38 | 12 | 15 | 15 | 22500-23000 | 27500-28000 | 3200 | 11 |

| OURS-6015-6C-Si | M16*1.0 | 60 | 6 | 15 | 15 | 18500-20500 | 2600 | 11 | |

| OURS-5020-4C-Si | 3/8-24UNF | 50 | 4 | 20 | 15 | 11500-12000 | 13500-14000 | 2000 | 8 |

| OURS-5020-6C-Si | 3/8-24UNF | 50 | 6 | 20 | 15 | 19000-21000 | 2600 | 8 | |

| OURS-5020-4C-Tr | M16*1.0 | 50 | 8 | 20 | 15 | 23000-24000 | 3200 | 8 | |

| OURS-5020-4C-Tr | M16*1.0 | 38 | 8 | 20 | 15 | 17500-18000 | 3200 | 8 | |

| OURS-3828-4C-Si | 3/8-24UNF | 38 | 4 | 28 | 15 | 8000-8500 | 1000 | 5 | |

| OURS-3035-4C-Si | M8.1.25 | 30 | 4 | 35 | 15 | 5200-5600 | 800 | 4 | |

| OURS-3040-4C-Si | M10*1.5 | 30 | 4 | 40 | 15 | 5200-5600 | 800 | 2 | |

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian