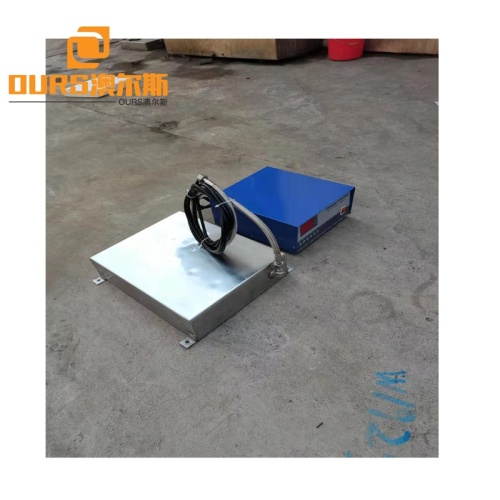

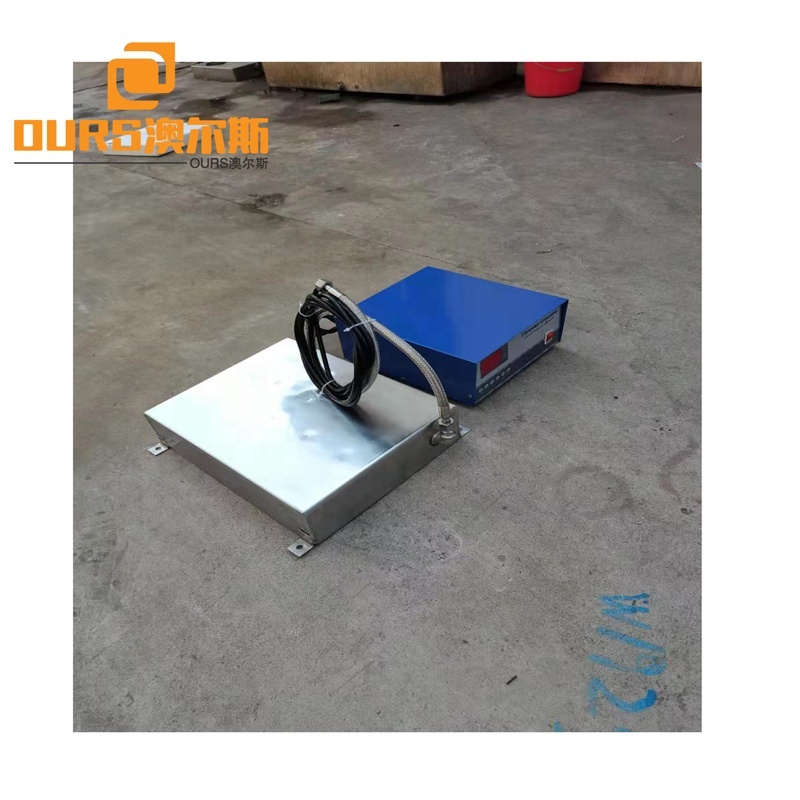

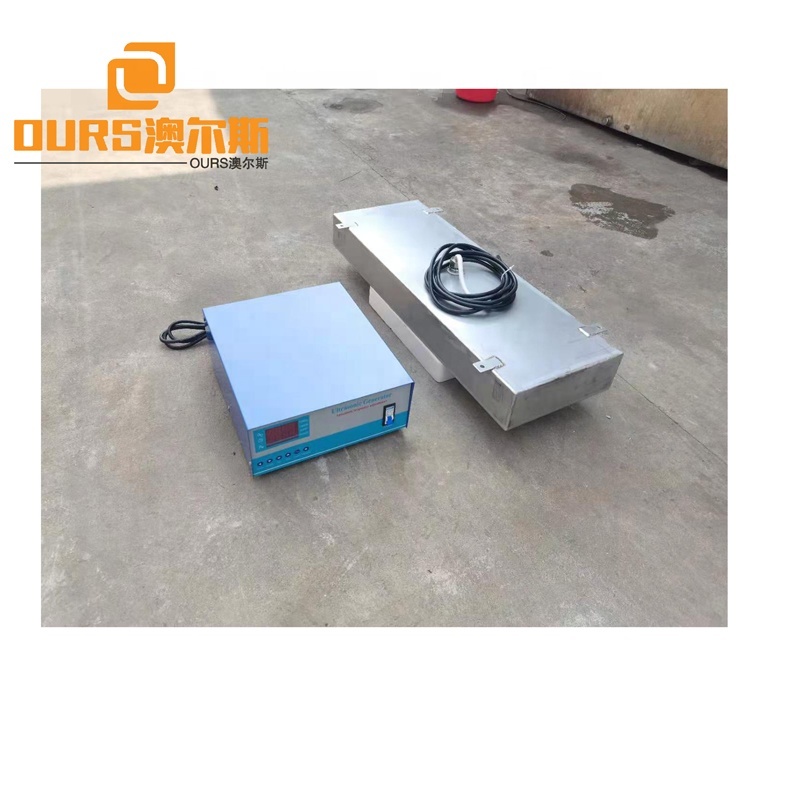

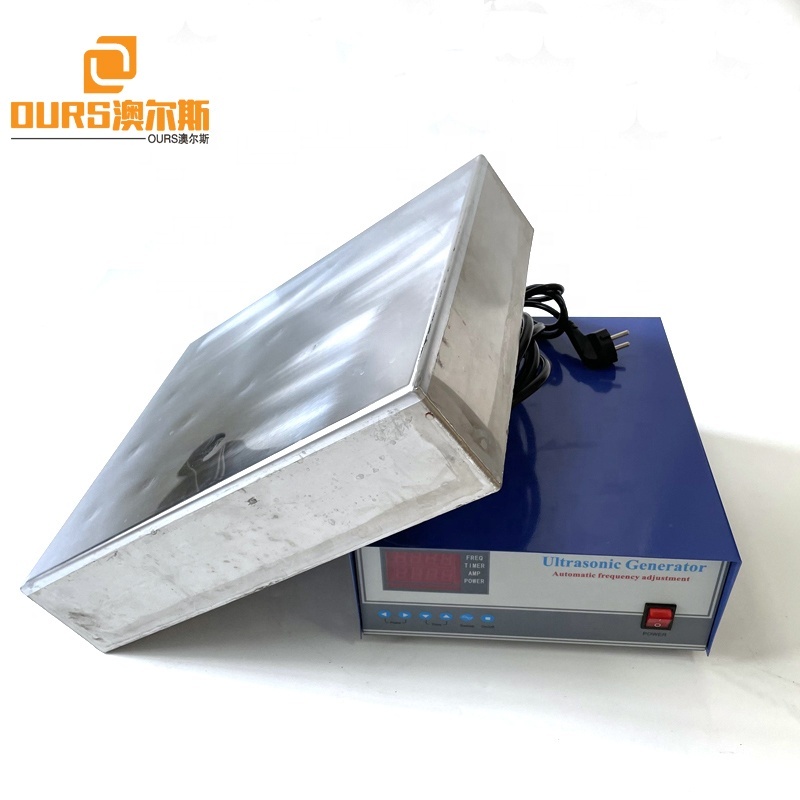

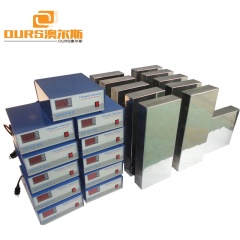

Waterproof Ultrasonic Submersible Transducer Cleaner Plate 28K 5000W Used For Industrial Cleaner Bearing Metal Parts Oil Rust

1-19 Set

$2,200.00

≥ 20 Set

$1,700.00

- Item No.202105179cf4aMOQ1 Set

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

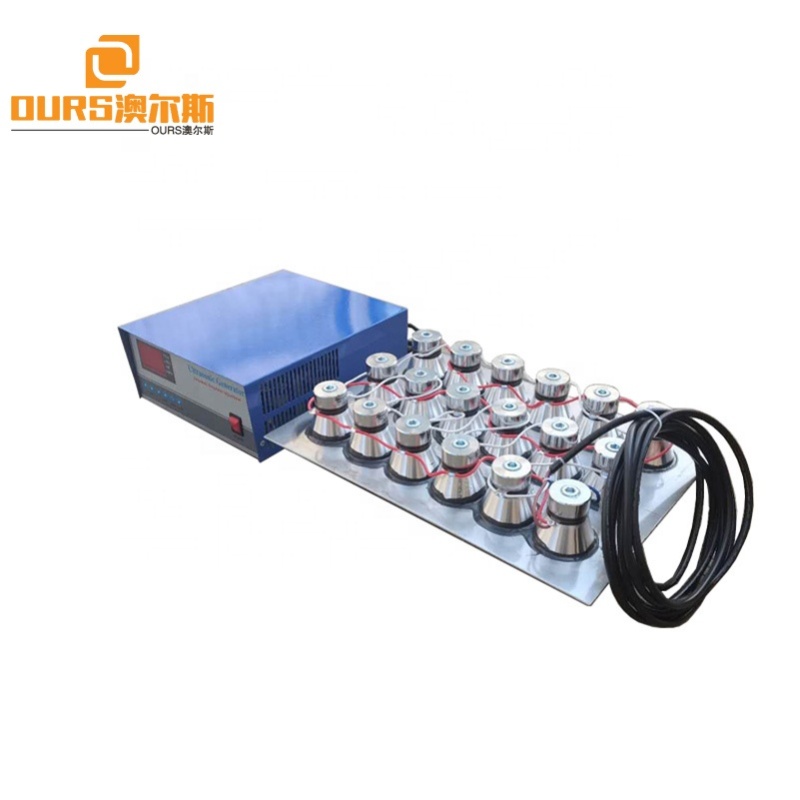

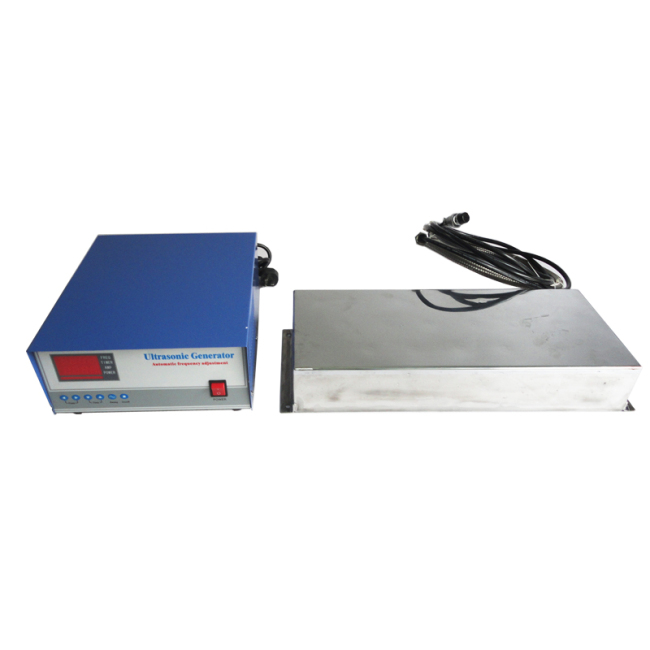

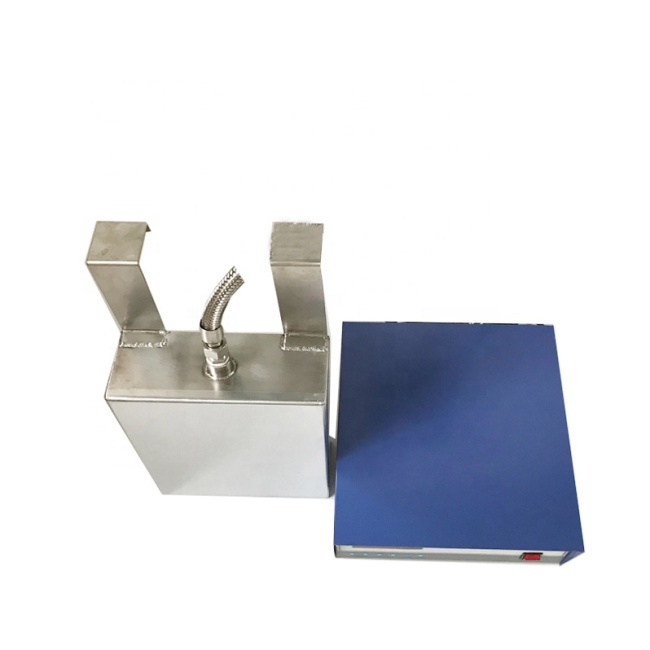

The ultrasonic vibration plate is made according to the actual situation of the user. It is made of high-quality stainless steel, welded top-tight, no water seepage, and the transducer adopts imported glue bonding and screw fixing methods to ensure that the transducer head does not fall off, which greatly extends the transducer The service life and the cleaning effect have also been significantly improved. It is mainly used in the cleaning line of the pharmaceutical industry and the pharmaceutical industry. It is also used in the cleaning line of the electronics, machinery, chemical, food and other industries. It can also be used on the inner wall of a single tank.

Ultrasonic vibration plate function:

1. Acceleration: the acceleration caused by the pushing of liquid particles. For the higher frequency ultrasonic cleaning machine, the cavitation effect is very insignificant. At this time, the cleaning mainly relies on the acceleration of the liquid particles under the ultrasonic action to impact the particles to perform ultra-precision cleaning of the dirt.

2. Cavitation: Cavitation is the transmission of ultrasonic waves to the liquid with an interactive high-frequency conversion method of compressive force and decompression force over 20,000 times per second. When the pressure is reduced, the vacuum core group bubbles are generated in the liquid. When the compression force is applied, the vacuum core group bubbles produce a strong impact force when crushed by pressure, thereby peeling off the dirt on the surface of the object to be cleaned, so as to achieve precision Purpose of cleaning.

3. Direct flow effect: The phenomenon that ultrasonic waves flow in the liquid along the sound propagation direction is called straight flow. When the sound wave intensity is 0.5W/cm2, the naked eye can see the straight-in flow, which is perpendicular to the vibrating surface, and the flow rate is about 10cm/s. Through this straight flow, the oily dirt on the surface of the object to be cleaned is stirred, and the cleaning liquid on the surface of the dirt also produces convection. The dissolving liquid that dissolves the dirt is mixed with the new liquid, which speeds up the dissolution rate, and plays a very important role in the transportation of the dirt. Great effect.

Ultrasonic vibration plate has the following characteristics:

1. All stainless steel structure, acid and alkali resistant, beautiful and durable. The split structure is adopted, and the vibration plate and the ultrasonic generator are connected by a high-frequency wire with a socket, which is convenient for use and maintenance.

2. Flexible installation and arrangement of ultrasonic vibration plate. The ultrasonic radiation surface can be arranged on the bottom, side or top surface of the cleaning tank as required.

Application scope of ultrasonic vibration plate:

1. Machinery industry: removal of anti-rust grease; cleaning of measuring tools; degreasing and rust removal of mechanical parts; cleaning of engines, carburetors and auto parts; dredging and cleaning of filters and screens, etc. Especially in the railway industry, it is very suitable for the degreasing and decontamination of the air conditioner of the train, and the derusting, degreasing and anti-rusting of the various parts of the train head.

2. Surface treatment industry: degreasing and rust removal before electroplating; cleaning before ion plating; phosphating treatment; removing carbon deposits; removing oxide scale; removing polishing paste; surface activation treatment of metal workpieces, etc.

3. Instrumentation industry: high cleanliness of precision parts, cleaning before assembly, etc.

4. Electronic industry: Removal of rosin and solder spots on printed circuit boards; cleaning of mechanical and electronic parts such as high voltage contacts.

5. Medical industry: cleaning, disinfection, sterilization of medical equipment, cleaning of test utensils, etc.

6. Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

7. Watch and jewelry industry: remove sludge, dust, oxide layer, polishing paste, etc.

8. Chemical and biological industries: cleaning and descaling of laboratory utensils, etc.

9. Optical industry: Degreasing, sweating and dust removal of optical devices.

10. Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

11. Petrochemical industry: cleaning and dredging of metal filter screens, cleaning of chemical containers, exchangers, etc.

12. Others: liquid defoaming (removing dissolved air) in photosensitive material manufacturing, papermaking, and certain food fields.

Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer | |

ARS-ZBH300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

ARS-ZBH600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

ARS-ZBH1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

ARS-ZBH1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

ARS-ZBH1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

ARS-ZBH1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

ARS-ZBH2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

ARS-ZBH2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

ARS-ZBH3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

ARS-ZBH5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

Above are single frequency ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian