1-499 Pieces

$12.00

500-999 Pieces

$11.50

≥1000 Pieces

$11.00

68KHZ 60W ultrasonic piezoelectric cleaner transducer For Cleaning Mold

The ultrasonic vibrator should be placed in a dry place to prevent the ultrasonic vibrator from getting damp and affecting normal work. If the ultrasonic vibrator is damp, put it in an oven and set about 100 ℃ to dry for 2 hours or use a hair dryer to remove moisture until the resistance value is normal; the ultrasonic vibrator is degummed, and the ultrasonic power output power after the ultrasonic vibrator is normal, but due to the vibrator and vibration If the surface connection is not good, the vibrator will be burnt out if you work for a long time. The degumming of the ultrasonic vibrator generally requires a professional ultrasonic manufacturer to repair or replace it.

Maintenance of ultrasonic vibrator:

If you have not used it for more than a week, please cover it with a dust cover (plastic bag); Except that the lifting screw has received lubricating oil before leaving the factory, other parts do not need any lubricating agent; Regularly check the internal vibrator output line for wear; Please wipe the dust with a clean cloth. Dry compressed air should be used to blow away the dust in the machine every six months. It is strictly forbidden to use various fluxes when cleaning the side plate and surface of the welding machine. Neutral detergent should be used and lightly wiped; When the water filter cup reaches 13 water level, please drain the water; every month the welding machine is used, the sliding parts should be wiped clean and re-coated with high-quality lubricating grease; always pay attention to the safety of the machine position.

Ultrasonic vibrator installation process:

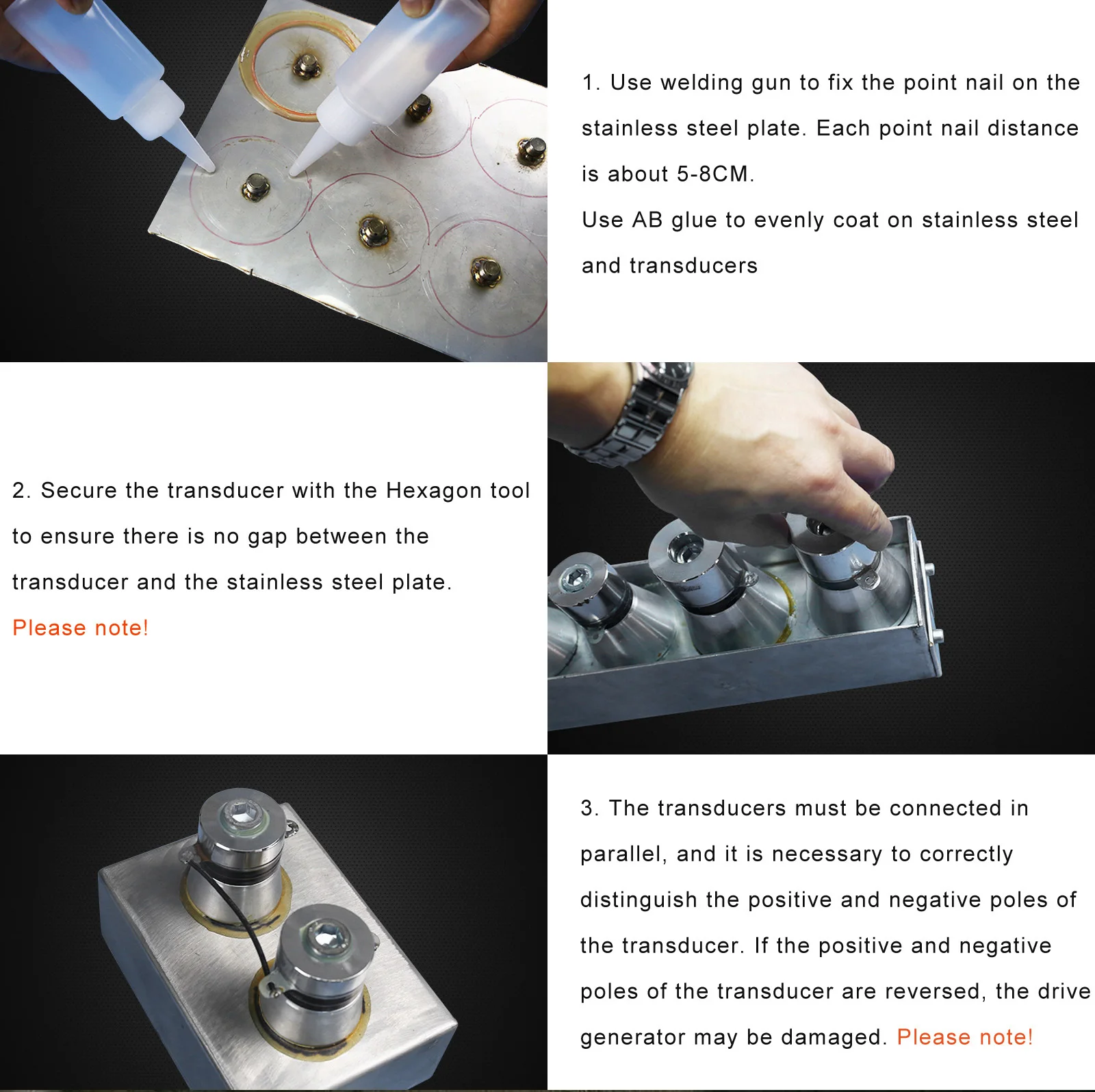

1. Preparation tools: Argon arc welding, No. 10 hexagon wrench, chromium iron tin wire, 2.5 square high temperature wire, 2*2.5 cable wire, vibrator glue, (wire stripper, casing, cable tie, sandblasting machine, Pipe fittings, etc.).

2. Welding screws: Calculate the arrangement of the vibrator, weld the screws at the cleaned position, and then clean the surrounding of the screw, be sure to make it flat, so as not to affect the installation of the vibrator.

3. Glue configuration: Squeeze the A glue around the screw, then squeeze the B glue next to the A glue, and then quickly mix the AB glue with a small iron rod to make it fully mixed.

4. Install the vibrating head: twist the transducer a little harder to squeeze out the air and excess glue between the bottom and the contact surface of the cylinder bottom, so that the vibrator is more tightly integrated with the stainless steel.

5. Curing and condensing: curing in a place with relatively high room temperature, 4-8 hours can be connected, 24 hours later, you can power on the test machine.

Note: 1. A metal nail machine can also replace argon arc welding.

2. The welding screws must be fully welded, otherwise they will fall off easily.

3. Regarding curing, temperature should be considered for the length of time. If the temperature is low, the time will be long, and if the temperature is high, it will be faster. It is recommended to operate at room temperature.

The principle of ultrasonic vibrator arrangement:

(1) Different product layouts have different requirements for cleaning, such as the degree of oil contamination of the product, the difficulty of cleaning, the level of cleaning requirements, and the design of cleaning processes, all require targeted selection.

(2) The arrangement of the vibrators is not the more dense the better, and the right one is the best.

3. Introduction to ultrasonic vibrator:

Ultrasonic vibrator, also called ultrasonic vibrating head, ultrasonic vibrating head, is a kind of ultrasonic transducer and the core component of ultrasonic cleaning machine. Industry standard name: Ultrasonic transducer, belongs to piezoelectric ceramic material, one of the main accessories of ultrasonic cleaning machine. In terms of power, a single ultrasonic vibration head is 60W and 100W. The frequencies are: 20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher; the difference in shape is: straight cylindrical shape, horn shape, etc.

The transducer uses different piezoelectric materials to explain that:

The black chip is P4 series, which is a medium power emitting material with dual transmitting and receiving characteristics.

With low dielectric loss and high mechanical quality factor, it is mainly used in ultrasonic cleaning, ultrasonic atomization and so on.

The Yellow chip is P8 series, which is a high-power emission material with high mechanical quality factor.

Good stability, very low dielectric loss, especially suitable for making high-power ultrasonic transducers. Widely used in

Ultrasonic welding, ultrasonic emulsification, ultrasonic polishing, ultrasonic cleaning and so on.

Main Features:

- High Q value.

- Large amplitude.

- High conversion frequency, low heat.

- Output is stable.

- Strict quality control.

Type | Length(mm) | Weight(g) | Frequency(KHz) | Resonance Impedance | Static Capacity | Input Power(W) |

ARS-QXHNQ3360 | 58 | 420 | 33 | 10-20 | 3800 | 60 |

ARS-QXHNQ4060 | 55 | 300 | 40 | 10-20 | 3800 | 60 |

ARS-QXHNQ4060 | 56 | 310 | 40 | 10-20 | 5400 | 60 |

ARS-QXHNQ4050-1 | 57 | 300 | 40 | 10-20 | 4100 | 50 |

ARS-QXHNQ5435 | 36 | 135 | 54 | 10-20 | 3200 | 35 |

ARS-QXHNQ6860 | 80 | 460 | 68 | 10-20 | 3800 | 60 |

ARS-QXHNQ68120 | 67 | 588 | 68 | 10-20 | 7800 | 120 |

ARS-QXHNQ8060 | 60 | 325 | 80 | 10-20 | 5400 | 60 |

ARS-QXHNQ12060 | 56 | 260 | 120 | 10-20 | 5400 | 60 |

ARS-QXHNQ13550 | 54 | 215 | 135 | 10-20 | 4200 | 50 |

68KHZ 60W ultrasonic piezoelectric cleaner transducer For Cleaning Mold

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]