1-499 Pieces

$6.50

≥500 Pieces

$6.00

High performance Piezo 40khz 60W Low Power Ultrasonic Cleaning Transducer For Cleaning Circuit Board

The mechanism of ultrasonic cleaning is to make use of the physical effects such as cavitation, radiation pressure and sound flow in the cleaning liquid. It can exfoliate the machinery produced by the dirt on the cleaning parts, and can also promote the chemical reaction between the cleaning liquid and the dirt, so as to achieve the purpose of cleaning the object. The frequency of the ultrasonic cleaning machine can be selected by 10~500 kHz according to the size and purpose of the cleaning material, generally more than 20~50 kHz. With the increase of the frequency of ultrasonic transducer, Langerhans oscillator, longitudinal oscillator and thickness oscillator can be used. In the miniaturization aspect, radial vibration and flexural vibration are also adopted. Ultrasonic cleaning has become more and more widely used in various industries, agriculture, household equipment, electronics, automobile, rubber, printing, aircraft, food, hospital and medical research.

Ultrasonic transducer application:

1. Among all the cleaning methods, ultrasonic cleaning is the most efficient and effective one. The reason why ultrasonic cleaning can achieve such an effect is closely related to its unique working principle and cleaning method.

2. We know that in production and life, there are many things that need to be cleaned, and there are many types and links that need to be cleaned, such as: removing contaminants from objects, dredging small holes, and common manual cleaning methods for special-shaped objects and hidden parts of objects. Undoubtedly, it cannot meet the requirements. Even steam cleaning and high-pressure water jet cleaning cannot meet the higher cleanliness requirements. Ultrasonic cleaning can also kill bacteria, dissolve organic pollutants, and prevent over-corrosion. Therefore, ultrasonic cleaning Is increasingly widely used in all walks of life:

(1) Machinery industry: removal of anti-rust grease; cleaning of measuring tools; degreasing and rust removal of mechanical parts; cleaning of engines, carburetors and auto parts; dredging and cleaning of filters and screens, etc.

(2) Surface treatment industry: degreasing and rust removal before electroplating; cleaning before ion plating; phosphating treatment; removing carbon deposits; removing oxide scale; removing polishing paste; surface activation treatment of metal workpieces, etc.

(3) Instrumentation industry: high cleanliness of precision parts, cleaning before assembly, etc.

(4) Electronic industry: Removal of rosin and solder spots on printed circuit boards; cleaning of mechanical and electronic parts such as high voltage contacts.

(5) Medical industry: cleaning, disinfection, sterilization of medical equipment, cleaning of laboratory utensils, etc.

(6) Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

(7) Watch first and decoration industry: remove sludge, dust, oxide layer, polishing paste, etc.

(8) Chemical and biological industries: cleaning and descaling of laboratory utensils.

(9) Optical industry: degreasing, sweating and dust removal of optical devices.

(10) Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

(11) Petrochemical industry: cleaning and dredging of metal filters, cleaning of chemical containers, exchangers, etc.

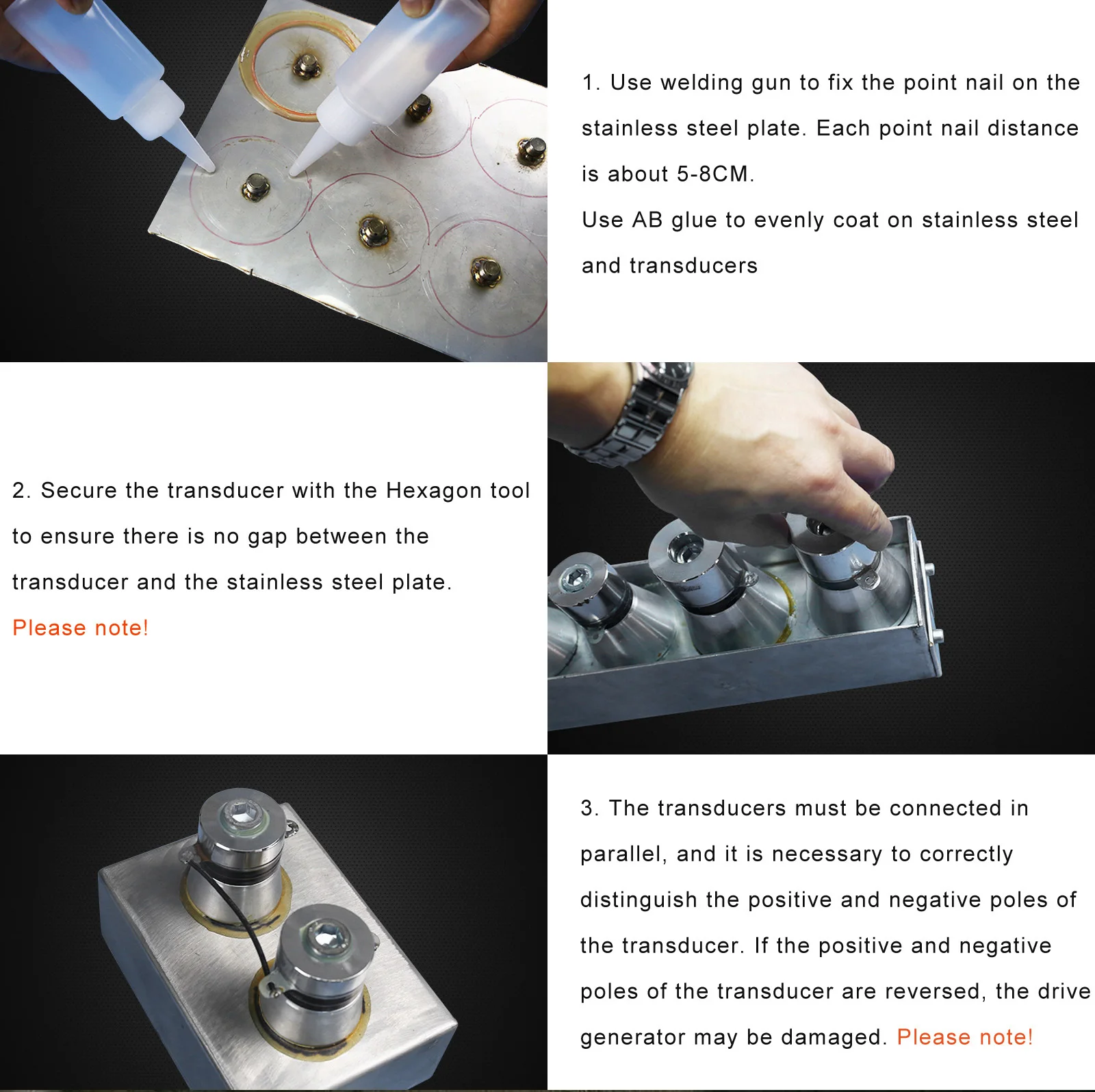

Install an ultrasonic oscillator, you must first understand the structure of the ultrasonic oscillator and the working principle of the ultrasonic oscillator. In fact, the ultrasonic oscillator is also called an ultrasonic oscillator.

The ultrasonic vibrator is a device that realizes the mutual conversion of electrical energy and mechanical energy (acoustic vibration) by the piezoelectric effect of piezoelectric ceramics, and amplifies the acoustic impedance matching front and rear radiation cover blocks. The ultrasonic vibrator is composed of an ultrasonic transducer and an ultrasonic horn. The ultrasonic transducer is a device that can convert high-frequency electrical energy into mechanical energy. The ultrasonic horn is a passive device that does not generate vibration itself. It only transmits the amplitude of the vibration input by the ultrasonic transducer before changing it. Impedance transformation.

Principle of ultrasonic vibrator arrangement:

(1) Cleaning different product layouts have different requirements, such as the degree of oil staining of the product, the difficulty of cleaning, the level of cleaning requirements, and the design of the cleaning process, all require targeted selection.

(2) The arrangement of the vibrators is not as dense as possible, and the right one is the best.

3. Introduction to ultrasonic vibrator:

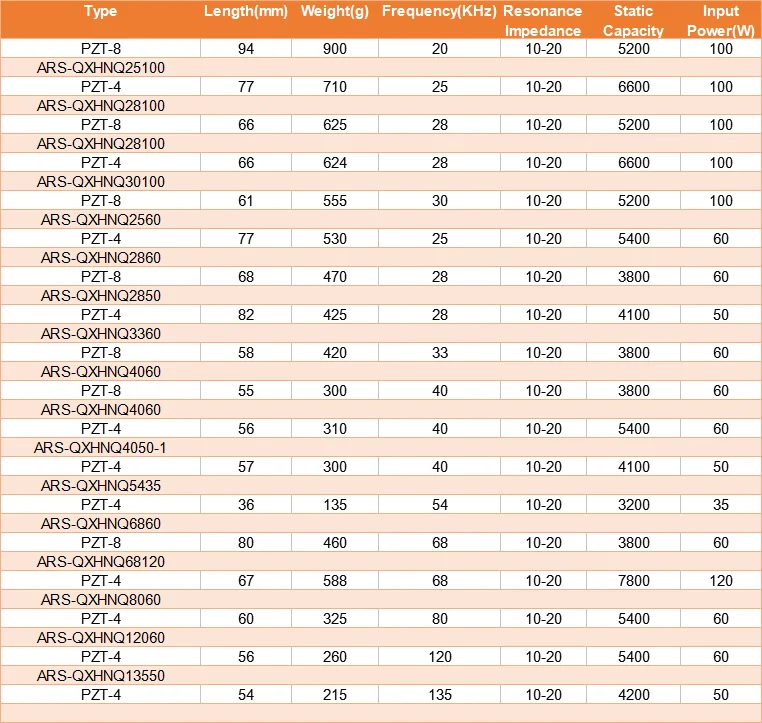

The ultrasonic vibrator, also called the ultrasonic vibrating head, is an ultrasonic transducer and is a core component of the ultrasonic cleaning machine. Industry standard name: Ultrasonic transducer, which belongs to piezoelectric ceramic material and one of the main accessories of ultrasonic cleaning machine. From the power point, a single ultrasonic head is 60W, 100W. The frequencies are: 20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher; the difference in shape is: straight cylindrical shape, horn shape, and the like.

Ultrasonic oscillator principle:

1. The piezoelectric element and the internal electrode are alternately stacked in the ultrasonic vibrator, and have an external electrode that is electrically connected to the internal electrode;

The ultrasonic transducer includes an internal electrode group that is substantially divided into four portions along a second direction and a third direction orthogonal to a lamination direction as the first direction, and a first external electrode group and a second external electrode group respectively The electrode group is turned on; by applying an alternating voltage to the first external electrode group and the second external electrode group, the longitudinal vibration mode in which the main vibration occurs in the second direction and the main vibration are in the third direction a bending vibration mode that occurs, thereby generating ultrasonic elliptical vibration;

The ultrasonic transducer includes a conductor film for electrode connection formed along a surface perpendicular to the stacking direction, and predetermined predetermined external electrodes of the first external electrode group and the second external electrode group The external electrodes are electrically connected. A device that converts electrical energy and acoustic energy by piezoelectric effect is called a piezoelectric transducer. The ultrasonic transducer provided by the company uses self-produced high-quality piezoelectric ceramic components, which are carefully designed, processed and tested to be bolts. The fastening type produces stable ultrasonic waves even when the load changes. It has the characteristics of large amplitude, high electroacoustic conversion rate, low heat generation, high reliability and good consistency.

High performance Piezo 40khz 60W Low Power Ultrasonic Cleaning Transducer For Cleaning Circuit Board

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]