1-9 Sets

$2,850.00

≥10 Sets

$2,650.00

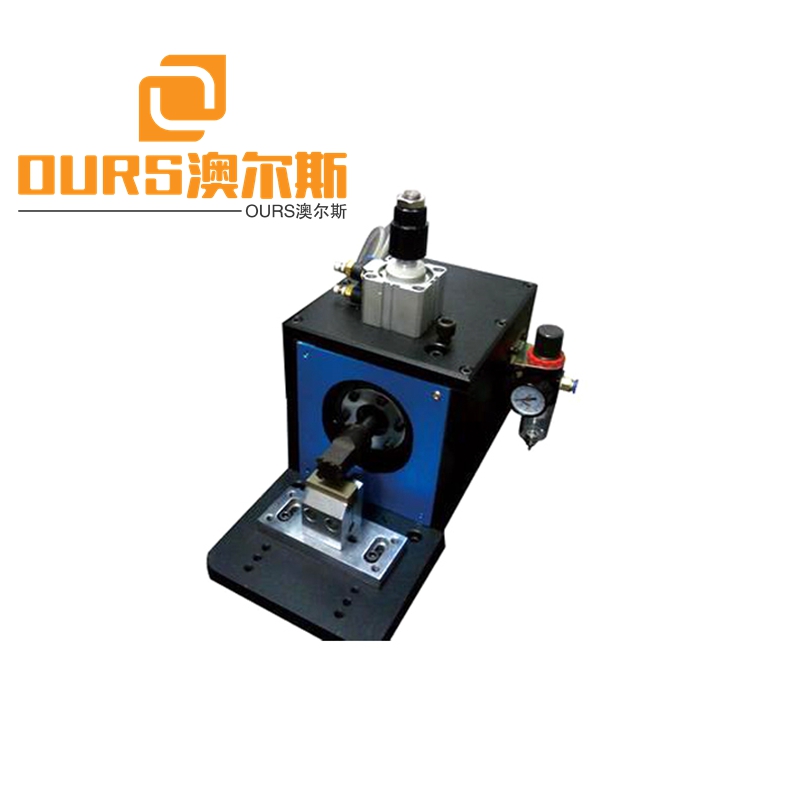

Factory Supply 20Khz 2000W Ultrasonic Wire Harness Welding Machine For Welding

![]()

Fully automatic frequency tracking and compensation function, quickly respond to the frequency fluctuation of the triple resonance system, and automatically save the best frequency for the next starting frequency

According to real-time load changes, the amplitude is automatically compensated to ensure the stable output of the equipment

The start-up rate is optional to ensure the smooth and rapid start-up of the triplex

Amplitude adjustable range

Two welding modes: time and energy

The generator can send out warning signals for frequency deviation, excessive current, excessive voltage, excessive temperature, power overload, etc.

Ultrasonic metal spot welding machine

Application range:

(1) The most common application areas of ultrasonic spot welding are semiconductor lead welding and IC circuit welding.

(2) Welding of battery pole pieces (welding of nickel tape + copper foil, nickel tape + aluminum tape, aluminum tape + aluminum foil, aluminum tape + aluminum cover, aluminum shell + aluminum nickel composite tape and other materials).

(3) Automotive electrical parts and other applications (welding of automotive wiring terminals, automotive wiring harnesses, motor terminals, relay sheets, electrolytic capacitor pole pieces, carbon brushes, heat sinks, etc.).

(4) Wires and famous electronic components, terminals, contacts, and connectors are fused to each other; wires are fused to each other, and one or more wires are fused together.

(6) Mutual melting of large heat sinks, heat exchange fins and honeycomb cores of famous household appliances and automotive products.

(7) Mutual melting of dissimilar metal sheets such as electromagnetic switches, non-fuse switches and other high-current contacts.

(8) Welding of non-crystalline alloy materials.

3. Features:

(1). The two objects to be welded are overlapped and joined by ultrasonic vibration and pressure to form a solid state, the joining time is short, and the joining part does not produce cast structure (rough surface) defects.

(2) Compared with the ultrasonic welding and resistance welding methods, the mold life is long, the mold repair and replacement time is less, and it is easy to realize automation.

(3) Ultrasonic welding can be carried out between the same metal and different metals, which consumes much less energy than electric welding.

(4) Compared with other pressure welding, ultrasonic welding requires less pressure, and the deformation amount is less than 10%, while the deformation of the workpiece in cold pressure welding is 40%-90%.

(5) Ultrasonic welding does not require pre-treatment of the welded surface and post-weld treatment like other welding.

(6) There is no need for external factors such as flux, metal filler, and external heating to handle ultrasonic welding.

(7) Ultrasonic welding can minimize the temperature effect of the material (the temperature of the welding zone does not exceed 50% of the absolute melting temperature of the welded metal), so as not to change the metal structure, so it is very suitable for welding applications in the electronic field.

Type | Power(W) | Frequency (KHz) |

ARS-JSHJ-800W35 | 800W | 35KHz |

ARS-JSHJ-800W40 | 800W | 40KHz |

ARS-JSHJ-1000W15 | 1000W | 15KHz |

ARS-SLHJ-1000W20 | 1000W | 20KHz |

ARS-SLHJ-1000W35 | 1000W | 35KHz |

ARS-SLHJ-1000W40 | 1000W | 40KHZ |

ARS-JSHJ-2000W20 | 2000W | 20KHZ |

ARS-JSHJ-2000W15 | 2000W | 15KHZ |

ARS-JSHJ-3200W15 | 3200W | 15KHZ |

ARS-JSHJ-4200W15 | 4200W | 15KHZ |

![]()

Factory Supply 20Khz 2000W Ultrasonic Wire Harness Welding Machine For Welding

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]