1-4 Sets

$2,200.00

≥5 Sets

$2,150.00

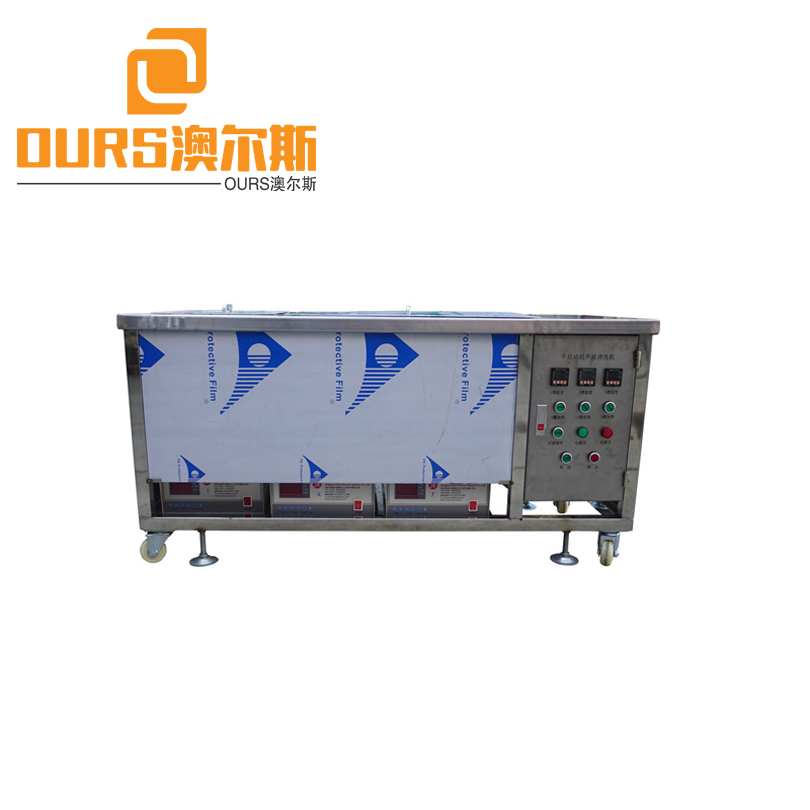

28khz/40khz 900W Multi Tank Digital Heated Industrial Ultrasonic Parts Washer & Cleaner For Vehicle Radiators

Multi-tank ultrasonic cleaning machine equipment description:

The cleaning machine is an ultrasonic equipment made of three stainless steel tanks. It is a continuous work consisting of ultrasonic rough washing system, ultrasonic fine washing system, rinsing, filtration circulation system, automatic temperature control heating system, frame and electric control system. installation. The operator puts the cleaning workpiece in the tooling basket, and the tooling basket with the workpiece is sent to each process section by manual or other conveying tools, and the workpiece is subjected to ultrasonic rough cleaning, ultrasonic fine cleaning, rinsing and other processes, and the whole machine cleaning part It is a semi-enclosed structure, and the power distribution facility of the equipment is an independent electric control cabinet.

Composition structure

The cleaning machine is mainly composed of ultrasonic generator, transducer, ultrasonic system, rinsing system, filter system, electrical control part, tank part, overflow system, drain, soundproof protective cover, etc.

The working principle of the multi-slot ultrasonic cleaning machine is to use the mechanical vibration with strong ultrasonic penetration to impact the surface of the workpiece and clean the workpiece with a cleaning agent to make the surface of the workpiece clean. The working process is to manually put the workpiece to be cleaned into the tooling basket, and clean it in sequence according to the cleaning process. After the cleaning is completed, the workpiece is manually taken out. This equipment is easy to operate. Closed appearance, beautiful and generous structure. High cleaning efficiency, consistent cleaning quality, suitable for mass production. The key parts of the electrical control of this equipment are imported high-quality parts with reliable performance and long service life.

Cleaning process:

Loading→ultrasonic cleaning→hot water rinse→ultrasonic rinse→hot water rinse→hot water rinse→hot water rinse→unloading

Multi-tank ultrasonic cleaning machine:

Generally, it is designed and manufactured according to the customer's workpiece cleaning requirements and cleaning volume, which can be respectively processed by ultrasonic cleaning or spray pre-washing, ultrasonic rinsing or spray rinsing or bubbling rinsing, wind cutting, drying, chemical polishing, oiling, etc. Requirements and process combinations. Due to the multi-tank cleaning method, the cleaning fluid can be multi-stage filtered and pure water rinsed, etc., which can effectively ensure the cleanliness of the product. According to the actual needs of customers, a semi-automatic transmission mechanism can be configured to flexibly meet the needs of customers. Kind of cleaning requirements.

Process flow:

Multiple cleaning methods can be combined, such as ultrasonic cleaning 28KHZ 40KHZ, etc. different frequencies; spray pre-washing; ultrasonic fine washing; ultrasonic rinsing; bubbling rinsing; wind cutting; drying; hot water meter adjustment; mechanical drying and so on. Combination cleaning or modular cleaning of single tanks with different functions has completed the process cleaning requirements of different orders.

Features:

The inner tank is made of stainless steel through shear bending or laser cutting, which is acid and alkali resistant and has a beautiful appearance.

High-Q transducer and high-power modular ultrasonic generator are used to make the ultrasonic output strong and powerful.

Adopting Swiss imported adhesive and bonding technology to ensure that the transducer can work for a long time at high water temperature and is durable.

The electric box adopts a strong frame structure and a silk screen panel, which is beautiful and durable.

Equipped with automatic temperature control heating device, temperature control range: normal temperature 30-110℃.

The ultrasonic generator and the cylinder have a separate structure and are connected by a high-frequency aviation plug.

Multiple rinsing tanks can be added, and the tank is equipped with a constant temperature device, and the cleaning and rinsing can be completed at one time.

A circulating drying system can be added to quickly dry the workpiece.

We use water-based cleaning agents that are safe, non-toxic, environmentally friendly and low in cost.

28khz/40khz 900W Multi Tank Digital Heated Industrial Ultrasonic Parts Washer & Cleaner For Vehicle Radiators

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]