2600W/20khz Made in China Ultrasound Ultrasonic Foam Board Cutting Machine NON Laser Cutter

1-499 Sets

$1,700.00

≥500 Sets

$1,650.00

Model Number

ARS-SLHJ260020

description

2600W/20khz Made in China Ultrasound Ultrasonic Foam Board Cutting Machine NON Laser Cutter

![]()

Ultrasonic spot welding in the plastics thermoplastics and structural foam materials

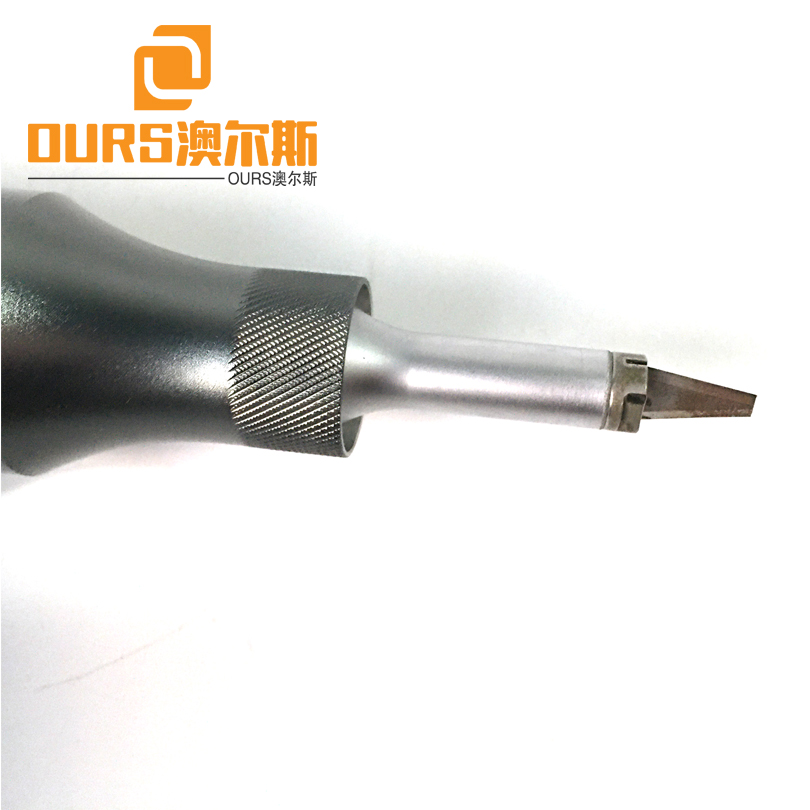

The hand-held sonotrode for ultrasonic welding (bonding) is light and handy, suitable for left- or right-handed operation. It is equipped with simple air-cooling system, which prevents the device from heating and the palm from sweating and this way facilitates the control and precise operation.

The ultrasonic hand-held sonotrode is equipped with an ultrasonic generator type. The horn and the handle are made of high—quality materials, that ensure long life and smooth operation.

Basic characteristics:

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

Product Specifications :

1 - hand welder can be The main function of the ultrasonic cutting process is to split the connected parts. The high frequency vibration per second can reduce the pressure on the object to be cut. In this way, a neat and clean cutting surface can be formed. In practical applications, it is divided into two processes, separate welding and cutting.

Separate welding

Ultrasound can be used to cut thermoplastic multilayer textiles, non-woven materials or films into arbitrary shapes, and simultaneously weld them along the cutting contour. The thermoplastic fiber content should be at least 20%. The anvil with the corresponding cutting contour is cut by the vibration generated by the ultrasonic system. At the same time, the vibration attenuation causes heat to be generated in the cutting area, thereby welding along the cutting edge.

The cutting blade vibrated by ultrasonic waves quickly and accurately separates the items to be cut with little resistance, and does not produce residue. Ultrasonic has been used for cutting finished products for many years. When cutting baked goods, energy bars, cheese, pizza and other materials, the vibrating (cold) cutting horn reduces the resistance during the cutting process and removes adhered product residues. The result: a flat surface that can be cut again is formed without deformation or thermal damage to the product.

The basic composition of an ultrasonic cutting knife is an ultrasonic transducer, horn, tool head (knife body), and driving power supply. The ultrasonic drive power converts the mains electricity into high frequency and high voltage alternating current, which is output to the ultrasonic transducer. The ultrasonic transducer is actually equivalent to an energy conversion device, which can convert the input electrical energy into mechanical energy, that is, ultrasound. Its manifestation is that the transducer stretches back and forth in the longitudinal direction. The frequency of the telescopic movement is equal to the frequency of the high-frequency alternating current supplied by the driving power supply. The role of the horn is to fix the entire ultrasonic vibration system, and the other is to adjust the output amplitude of the transducer. On the one hand, the tool head (cutter body) amplifies the amplitude and focuses the ultrasound. On the other hand, it outputs ultrasonic waves, and uses the similar cutting edge of the cutting knife to concentrate the ultrasonic energy into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, this part instantly softens and melts, and its strength drops greatly. At this time, as long as a small cutting force is applied, the purpose of cutting can be achieved.

Advantages of ultrasonic cutting

1. Air-cooled and water-cooled designs can be adopted to adapt to various working conditions and environments

2. The cutting speed is greatly improved, and the efficiency is more than 10 times higher than that of the traditional cutting knife

3. Use high-power ultrasonic transducer as vibrating element to ensure long-term stable work

4. The variety of cutting tools is complete, and cutting tools with relevant shapes can also be customized according to customer processes

5. It can cut all kinds of products that are difficult to cut by ordinary tools, and solve the production and processing problems

6. High hardness blades can be installed, and the cutting blades can be replaced, which reduces the cost of use

7. Easy to install and use, hardly changing the original cutting process

8. High cutting precision, good cut surface finish

main application:

Tire crown; nylon; steel wire belt plastic layer; nylon cord; inner lining; sidewall; apex; triangle ring, etc.;

other apps:

Printed circuit boards; natural fibers; synthetic fibers; non-woven fabrics; thin synthetic resins; model making; all forms of paper; bottom film; food (cake, sugar, meat). to a single point welding, screw implants , riveting .

2 - Portable design , save space , easy to operate.

3 - can be used independently , but also can be used with automatic peripheral equipment .

4 - There are lessons device models , especially for rhinestones / PC drill mount in haute couture processing .

The hand-held sonotrode for ultrasonic welding (bonding) is light and handy, suitable for left- or right-handed operation. It is equipped with simple air-cooling system, which prevents the device from heating and the palm from sweating and this way facilitates the control and precise operation.

The ultrasonic hand-held sonotrode is equipped with an ultrasonic generator type. The horn and the handle are made of high—quality materials, that ensure long life and smooth operation.

Basic characteristics:

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

Product Specifications :

1 - hand welder can be The main function of the ultrasonic cutting process is to split the connected parts. The high frequency vibration per second can reduce the pressure on the object to be cut. In this way, a neat and clean cutting surface can be formed. In practical applications, it is divided into two processes, separate welding and cutting.

Separate welding

Ultrasound can be used to cut thermoplastic multilayer textiles, non-woven materials or films into arbitrary shapes, and simultaneously weld them along the cutting contour. The thermoplastic fiber content should be at least 20%. The anvil with the corresponding cutting contour is cut by the vibration generated by the ultrasonic system. At the same time, the vibration attenuation causes heat to be generated in the cutting area, thereby welding along the cutting edge.

The cutting blade vibrated by ultrasonic waves quickly and accurately separates the items to be cut with little resistance, and does not produce residue. Ultrasonic has been used for cutting finished products for many years. When cutting baked goods, energy bars, cheese, pizza and other materials, the vibrating (cold) cutting horn reduces the resistance during the cutting process and removes adhered product residues. The result: a flat surface that can be cut again is formed without deformation or thermal damage to the product.

The basic composition of an ultrasonic cutting knife is an ultrasonic transducer, horn, tool head (knife body), and driving power supply. The ultrasonic drive power converts the mains electricity into high frequency and high voltage alternating current, which is output to the ultrasonic transducer. The ultrasonic transducer is actually equivalent to an energy conversion device, which can convert the input electrical energy into mechanical energy, that is, ultrasound. Its manifestation is that the transducer stretches back and forth in the longitudinal direction. The frequency of the telescopic movement is equal to the frequency of the high-frequency alternating current supplied by the driving power supply. The role of the horn is to fix the entire ultrasonic vibration system, and the other is to adjust the output amplitude of the transducer. On the one hand, the tool head (cutter body) amplifies the amplitude and focuses the ultrasound. On the other hand, it outputs ultrasonic waves, and uses the similar cutting edge of the cutting knife to concentrate the ultrasonic energy into the cutting part of the material to be cut. Under the action of huge ultrasonic energy, this part instantly softens and melts, and its strength drops greatly. At this time, as long as a small cutting force is applied, the purpose of cutting can be achieved.

Advantages of ultrasonic cutting

1. Air-cooled and water-cooled designs can be adopted to adapt to various working conditions and environments

2. The cutting speed is greatly improved, and the efficiency is more than 10 times higher than that of the traditional cutting knife

3. Use high-power ultrasonic transducer as vibrating element to ensure long-term stable work

4. The variety of cutting tools is complete, and cutting tools with relevant shapes can also be customized according to customer processes

5. It can cut all kinds of products that are difficult to cut by ordinary tools, and solve the production and processing problems

6. High hardness blades can be installed, and the cutting blades can be replaced, which reduces the cost of use

7. Easy to install and use, hardly changing the original cutting process

8. High cutting precision, good cut surface finish

main application:

Tire crown; nylon; steel wire belt plastic layer; nylon cord; inner lining; sidewall; apex; triangle ring, etc.;

other apps:

Printed circuit boards; natural fibers; synthetic fibers; non-woven fabrics; thin synthetic resins; model making; all forms of paper; bottom film; food (cake, sugar, meat). to a single point welding, screw implants , riveting .

2 - Portable design , save space , easy to operate.

3 - can be used independently , but also can be used with automatic peripheral equipment .

4 - There are lessons device models , especially for rhinestones / PC drill mount in haute couture processing .

Specifications

1. ultrasonic generator + ultrasonic transducer+ horn.

ultrasonic welding machine for plastic

1.PP,ABS,AS,PS,nylon welding

2.high power and strong

3.good quality with best price

Ultrasonic welding machine for plastic remains one of the fastest techniques for welding smaller thermoplastic parts. In ultrasonic welding, one part is held stationary in a holding fixture while the other part is vibrated acoustically against it under pressure, creating frictional heat at their joining surfaces.

Applications:

Ultrasonic welding machine for plastic is widely used in auto industry, electron industry, medical treatment industry, office supply, packaging industry, and toy industry, etc. For example,

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-300 | 300W | 15khz |

ARS-DHJ-300 | 300W | 20khz |

ARS-DHJ-300 | 300W | 28khz |

ARS-DHJ-300 | 300W | 35KHz |

ARS-DHJ-300 | 300W | 40khz |

ARS-DHJ-500 | 500W | 15khz |

ARS-DHJ-500 | 500W | 20khz |

ARS-DHJ-500 | 500W | 28khz |

ARS-DHJ-500 | 500W | 35KHz |

ARS-DHJ-500 | 500W | 40khz |

ARS-DHJ-800 | 800W | 15khz |

ARS-DHJ-800 | 800W | 20khz |

ARS-DHJ-800 | 800W | 28khz |

ARS-DHJ-800 | 800W | 35KHz |

ARS-DHJ-800 | 800W | 40khz |

ARS-DHJ-900 | 900W | 15KHz |

ARS-DHJ-900 | 900W | 20khz |

ARS-DHJ-1000 | 1000W | 15KHz |

ARS-SLHJ2600 | 2600W | 20khz |

![]()

2600W/20khz Made in China Ultrasound Ultrasonic Foam Board Cutting Machine NON Laser Cutter

Have more questions about this product?

Scan the QR code with your phone, or visit the URL

Have more questions about this product?

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]