50-499 Pieces

$2.80

≥500 Pieces

$2.40

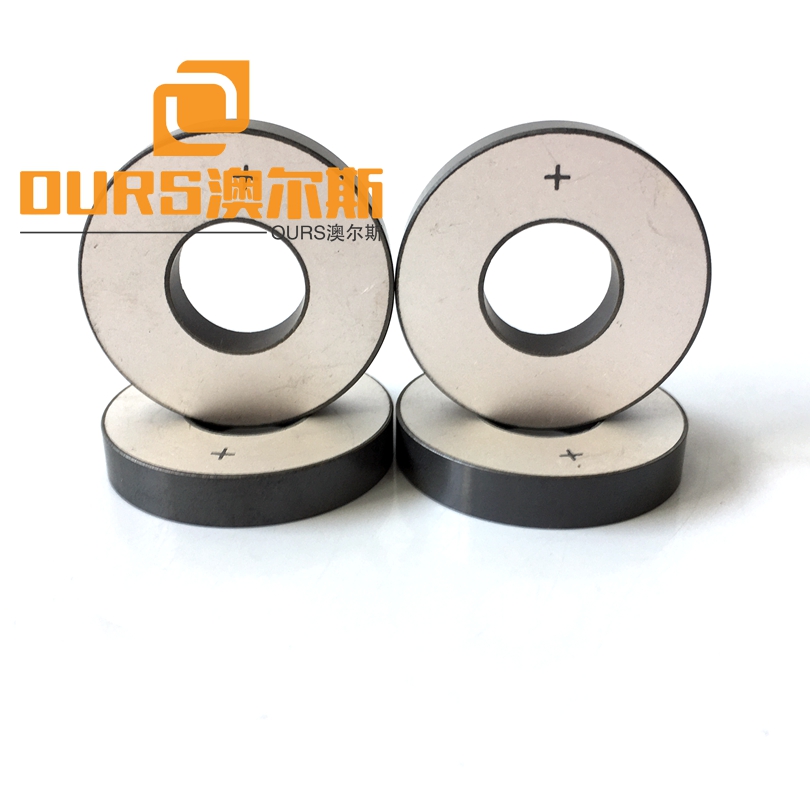

38*15*5mm Piezoelectric Element Piezo Ceramic Ring For Ultrasonic Cleaning Oscillator

![]()

The principle of the piezoelectric ceramic transducer is that when pressure or tension is applied to the ceramic chip, charges of opposite polarity are generated at the two ends of the ceramic chip, and a current is generated through the circuit. This effect is called the piezoelectric effect. Therefore, in the design of ultrasonic transducers, various factors should be considered, such as acoustic impedance, frequency response, impedance matching, acoustic structure, vibration mode and conversion materials, and how to design and coordinate these factors to achieve electro-acoustic conversion. best value. As a kind of energy transmission network, piezoelectric ceramic transducer has the problem of energy conversion efficiency.

The conversion efficiency is related to the selection of the transducer material, the form of vibration, the structure of the mechanical vibration system (including the support mechanism), and the operating frequency. Therefore, the problem of the ultrasonic transmitter is solved. There are two materials for piezoelectric ceramic transducers: magnetostrictive metal and piezoelectric ceramics. Piezoelectric ceramic transducer is an electronic ceramic material with piezoelectric characteristics. The main difference from a typical piezoelectric quartz crystal that does not contain ferroelectric components is that the main component of the crystal phase is all ferroelectric crystal grains. Ceramics are polycrystalline aggregates with randomly oriented grains, so the spontaneous polarization vector of each ferroelectric grain is also disoriented.

If a transducer made of such piezoelectric ceramics is put into water, then under the action of sound waves, charges will be induced at both ends of the transducer, which is a sound wave receiver. In addition, the piezoelectric effect is reversible. If an alternating electric field is applied to a piezoelectric ceramic sheet, the ceramic sheet will become thinner and thicker from time to time, and it will vibrate and emit sound waves. In order to make the ceramic exhibit macroscopic piezoelectric properties, the piezoelectric ceramic must be polarized in a strong DC electric field after firing, and the end face is subjected to multiple electrodes, so that the polarization vector of the original disordered orientation is preferentially oriented in the direction of the electric field, and after the electric field is eliminated , The piezoelectric ceramic after polarization treatment will maintain a certain macroscopic residual polarization strength, so that the ceramic has a certain pressure.

In order to improve the reliability of piezoelectric ceramics, we usually use metal shell packaging to reduce the lateral force that external mechanical structures may bring to piezoelectric ceramics. However, even if piezoelectric actuators that use shell packaging are used, it is necessary to go deeper Understand the technical background of piezoelectric ceramic applications, and ensure high reliability through proper design and operation.

Even if the structure of the piezoelectric system has proven to be reliable, any seemingly minor changes need to be re-evaluated. In some practical applications, the reliability of piezoelectric ceramics is often discussed under the following two extreme conditions.

Every link in the operation process must be strictly controlled, through actual testing and evaluation procedures, to avoid overloading, unreasonable mechanical structure, mechanical compensation and correction of inappropriate driving conditions, so as to achieve high reliability.

Piezoelectric ceramics can output performance based on limited parameters in a short time, but we would not recommend this method. When long-term reliability, long-term operation and high duty cycles are necessary conditions, the successful short-term test of a piezoelectric system does not mean that it is equally safe and reliable for long-term use. Incorrect operation will not immediately damage the piezoelectric ceramics, but will reduce long-term reliability and fail to achieve the expected working cycle.

The reliability of piezoelectric ceramics is affected by the mechanical structure of the load, drive control, and operating environment and other conditions; in most applications, due to cost reasons, users often want to use piezoelectric ceramics as small as possible. However, this makes the pressure Electroceramic components have become the weakest link in many mechanical design structures. In addition, piezoelectric ceramics are a relatively complex material and very sensitive. Improper handling can easily cause damage.

Ring piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

PiezoelectricCeramics (PZT) materials are categorized as functional ceramics. In sensors they make it possible toconvert forces, pressures and accelerations into electrical signals, and in sonic and ultrasonic transducers and actuators they convert electric voltages into vibrations or deformations.PiezoelectricCeramics materials are classified according to their chemical composition on the one hand, and by the specific application conditions on the other.

Application

1. ultrasonic cleaning trasnducer

2. ultrasonic welding tansducer

3. ultrasonic beauty transducer

4. ultrasonic underwater transducer

5. ultrasonic immersible transucer

6. ultrasonic screening transducer

7. ultrasonic cutting transducer

8. ultrasonic atomization transducer

9. ultrasonic emulsifier

FOR MORE OEM SIZE WELCOME TO ENQUIRE SALERS

![]()

38*15*5mm Piezoelectric Element Piezo Ceramic Ring For Ultrasonic Cleaning Oscillator

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]