1-4 Sets

$7,250.00

≥5 Sets

$7,000.00

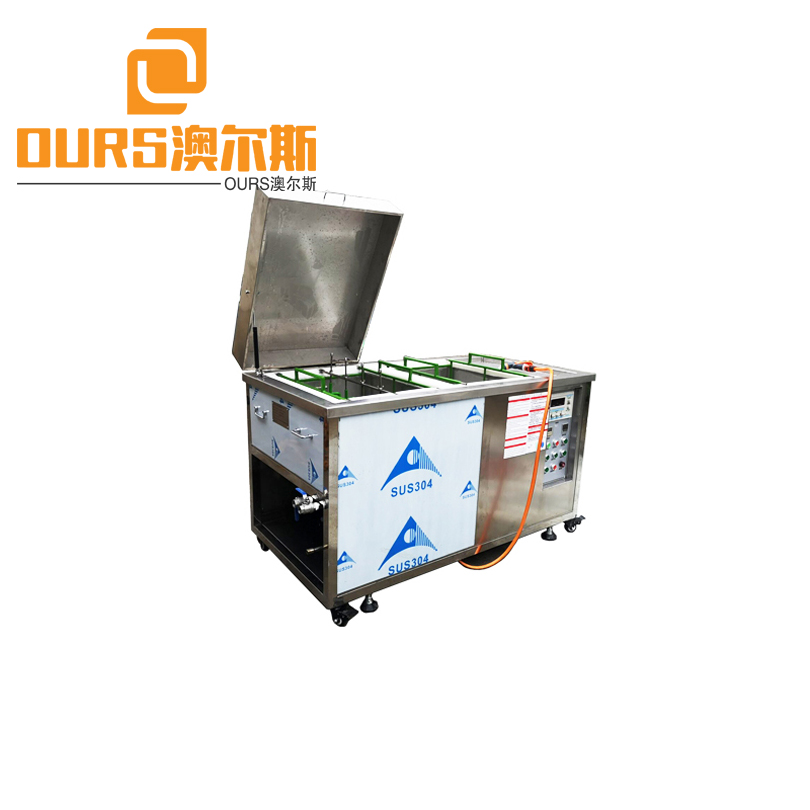

40KHZ 1500W 30L Injection Moulding Plastic Ultrasonic Cleaning For Cleaning Button Mould

Principle of electrolytic mold cleaning machine: electrolysis is the process of chemical decomposition of substances under the action of electric current. During the electrolysis process, the dirt on the metal surface begins to fall off, and the peeling is accelerated under the impact of ultrasonic waves. The metal surface is stained with animal and vegetable oils, minerals Oil, paraffin, carbon deposit, oxide layer. Use electrolysis to remove these dirt. When the current passes through the mold electrolytic cleaning agent containing a special formula, oxygen is generated near the positive electrode of the electrolytic cell, and hydrogen is generated near the negative electrode. Put the metal parts to be cleaned into the positive electrode of the electrolytic cell, and there will be small particles on the metal surface during the electrolysis These small bubbles cause the dirt to peel off the metal surface. Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to convert the transducer to mechanical energy from electrical energy. During this process, the transducer transfers huge energy to the cleaning tank solution. , Generate positive and negative pressure zones in the liquid, forming tens of thousands of cavitation bubbles, which continuously form explosions, impact the surface of the cleaned metal object, and quickly remove the dirt on the metal surface. To achieve the cleaning of the mold and restore the mold True color

Electrolysis mold function, the dirt is produced by the action of electric current to produce positive and negative molecules, through the catalytic action of oxygen and hydrogen generated on the metal surface, the dirt part is quickly decomposed, peeled off and surfaced; using the cavitation effect of ultrasound , Produce countless small bubbles and collide with the object. Impact blasting the dirt on the workpiece to automatically peel off the dirt. Mold cleaning uses a special solution to quickly decompose the dirt through a sufficient chemical effect. Completely remove any dirt on the surface of the mold, even any mold with a complex shape can remove dirt, and has a good rust prevention function, which greatly reduces the product defect rate after mold cleaning.

Compared with traditional mold cleaning methods, mold cleaning machine cleaning operation time can be shortened to an astonishing degree.

Plastic mold-ultrasonic cleaning machine has been approved by Japanese, Korean, Taiwanese, and Hong Kong-owned factories, breaking the monopoly of foreign imports; mastering a series of plastic, rubber, silicone, acetate, bakelite molds The cleaning process can effectively and thoroughly remove the residual high-temperature oxides on the mold; rust spots and oil residues; the plastic mold cleaning machine ranks first in the industry.

Equipment use: Used for cleaning plastic molds, modules, modules, mold cores, inserts, inserts, high-temperature carbon deposits, sulfide, gas, degreasing, and rust removal.

Brief introduction of electric control of electrolytic ultrasonic mould cleaning machine

1. Equipment use; used for cleaning of precision optical molds, optical light guide plate molds, and cleaning of oxides, gas, high temperature residues, oil stains, and carbon deposits on optical molds.

1. Using Mitsubishi PLC and touch screen to control operation, there are four programs to control the cleaning process.

2. The cleaning time and cleaning process can be set freely on the touch screen; there are 3 automatic cleaning process procedures and multiple manual cleaning procedures.

3. There are fault displays on the control screen, such as low liquid level display, discharge display, pump overcurrent display, and working display.

4. There is a record of cleaning times and an acousto-optic alarm device.

Scope of application

Gold molding, metal products, optics, machinery, locomotives, semiconductors, medical, communications and other industries

Type | Frequency (Khz) | Power(W) | Capacity(L) |

ARS-MJQXJ-18LTT | 28KHZ,40KHZ | 1000W | 18L |

ARS-MJQXJ-20LTT | 28KHZ,40KHZ | 1200W | 20L |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1500W | 30L |

ARS-MJQXJ-40LTT | 28KHZ,40KHZ | 1700W | 40L |

ARS-MJQXJ-50LTT | 28KHZ,40KHZ | 2500W | 50L |

ARS-MJQXJ-60LTT | 28KHZ,40KHZ | 3000W | 60L |

ARS-MJQXJ-70LTT | 28KHZ,40KHZ | 3600W | 70L |

ARS-MJQXJ-80LTT | 28KHZ,40KHZ | 4000W | 80L |

ARS-MJQXJ-100LTT | 28KHZ,40KHZ | 5000W | 100L |

ARS-MJQXJ-115LTT | 28KHZ,40KHZ | 5200W | 115L |

ARS-MJQXJ-400LTT | 28KHZ,40KHZ | 6000W | 400L |

40KHZ 1500W 30L Injection Moulding Plastic Ultrasonic Cleaning For Cleaning Button Mould

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]