1-4 Sets

$8,250.00

≥5 Sets

$8,050.00

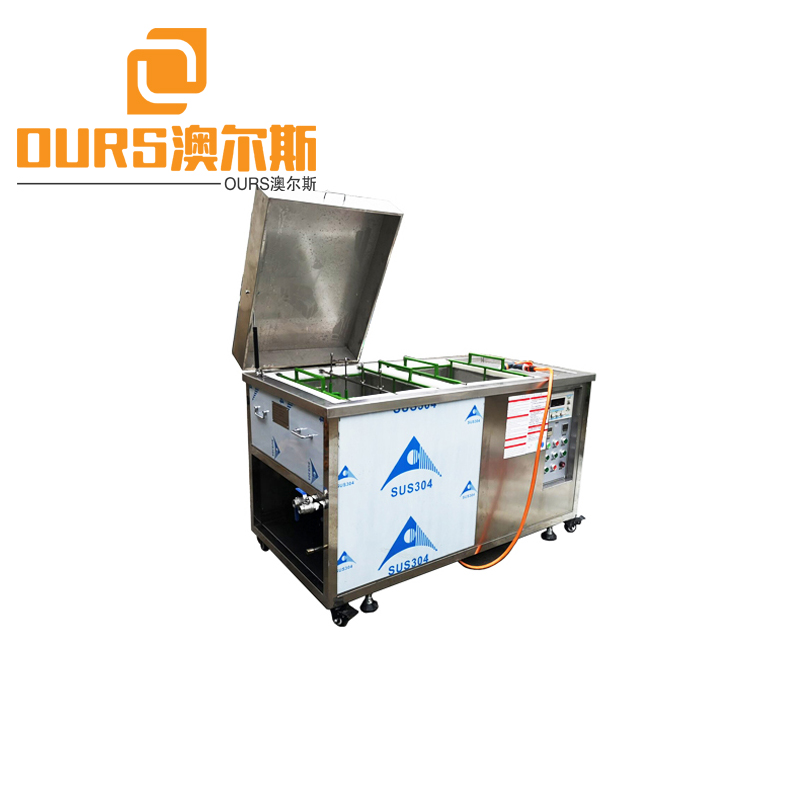

40KHZ 80L 4000W Plastic Injection Mold Cleaning For Cleaning Connector Mold

Principle of the electrolytic mold cleaning machine: electrolysis is the process of chemical decomposition of substances under the action of electric current. During the electrolysis process, the dirt on the metal surface begins to fall off, and the peeling is accelerated under the impact of ultrasonic waves. The metal surface is stained with animal and vegetable oils, minerals Oil, paraffin, carbon deposit, oxide layer. Use electrolysis to remove these dirt. When the current passes through the mold electrolytic cleaning agent containing a special formula, oxygen is generated near the positive electrode of the electrolytic cell, and hydrogen is generated at the negative electrode. Put the metal parts to be cleaned into the positive electrode of the electrolytic cell, and there will be fines on the metal surface during the electrolysis process. These small bubbles cause the dirt to peel off the metal surface. Ultrasonic cleaning is a process in which a 40KHZ high-frequency power supply is used to convert the transducer to mechanical energy from electrical energy. During this process, the transducer transfers huge energy to the cleaning tank solution. , Generate positive and negative pressure zones in the liquid, forming tens of thousands of cavitation bubbles, which continue to form explosions, impact the surface of the cleaned metal object, and quickly release the dirt on the metal surface. To clean the mold and restore the mold True color

Voltage 0-15V Current 0-50A Built-in electrolytic ultrasonic cleaning machine Cleaning process: The electrolytic ultrasonic system is composed of an ultrasonic generator system, an electrolytic circuit system, a circulating filter system, a special gold-type cleaning fluid and a water-based rust inhibitor.

The electrolytic cleaning system emits gas to the metal surface, using the sauna effect to remove the dirt and impurities on the metal surface, and can also completely remove the resin component; the dirt is peeled off by ultrasonic vibration, and the metal is attached to the cathode, even if it is quite Dirt in small corners can also be completely removed

Restore the metal to its original beauty.

Even complex shapes can remove dirt.

Can completely clean and decontaminate.

It has a good rust-removing and anti-rust effect.

It saves one hour of time than manual cleaning.

It is more environmentally friendly and safer than using organic solvents.

Greatly reduce the defective rate after washing.

Process: 1. Gold type washing → 2 running water washing → 3 anti-rust project.

Scope of application: metal plastic molds, precision molds, semiconductors, medical care, communications, auto parts

Ultrasonic output frequency according to different working conditions to fine-tune the ultrasound sweep line, to improve the cleaning efficiency. Optional additional features: ultrasonic output power continuously adjustable, you can display the range 10 - 100%; digital The ultrasonic generator using IGBT module, microcontroller technology, more stable working state, the output power is more powerful.

Ultrasonic single tank Product Features:

imported stainless steel plate and components, stainless steel structure, beautiful appearance and durable.

cleaning tank with heating and temperature control devices, temperature control range 30 ~ 110 ℃. .

imported high quality transducer, strong ultrasonic power output.

cleaning tank and generator uses a split-body design, easy to use.

The generator using the new circuit, power adjustable.

ultrasonic vibration, respectively, bottom of vibration and both side vibration, suitable for different cleaning requirements.

ultrasonic cleaning tank, in addition to standard sizes according to customer requirements.

Multi tank ultrasonic cleaning machine using city water, pure water, alkaline or weak acidic, aqueous solvent for cleaning agent, multi and spraying, jet, hot dipping, bubble and cleaning method combined with suitable drying method, semi automatic ultrasonic cleaning production line. Especially suitable for small quantities of electronic circuit boards, electronic parts, clock parts, metal stamping parts, metal parts, jewelry, jewelry, glasses, glass, semiconductor wafers, such as cleaning. With unique technology, strong targeted, simple structure, easy to use and so on, and the equipment cost is low, the investment is little, and can meet the special cleaning requirements of different products.

Application:

(1) Machinery industry: removal of rust-proof grease; cleaning of measuring tools; degreasing and rust removal of mechanical parts; cleaning of carburetors and automobile parts; dredging and cleaning of filters and screens.

(2) Surface treatment industry: degreasing and rust removal before electroplating; cleaning before ion plating; phosphating treatment; removal of carbon deposits, removal of oxide scale; removal of polishing paste; activation treatment of metal workpiece surfaces

(3) Instrumentation industry: cleaning of high-precision parts before assembly, etc.

(4) Electronics industry: removing rosin and welding spots on printed circuit boards; cleaning mechanical and electronic parts such as high-voltage contacts.

(5) Medical industry: cleaning, disinfection, sterilization of medical equipment, cleaning of experimental utensils, etc.

(6) Semiconductor industry: high cleanliness cleaning of semiconductor wafers.

(7) Clock and watch industry: decoration sludge, dust, oxide layer, polishing paste, etc.

(8) Chemical and biological industries: cleaning and descaling of experimental utensils.

(9) Optical industry: degreasing, sweat removal, dust removal, etc. of optical devices.

(10) Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc.

(11) Petrochemical industry: cleaning and dredging of metal filters, cleaning of chemical containers, exchangers, etc.

Type | Frequency (Khz) | Power(W) | Capacity(L) |

ARS-MJQXJ-18LTT | 28KHZ,40KHZ | 1000W | 18L |

ARS-MJQXJ-20LTT | 28KHZ,40KHZ | 1200W | 20L |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1500W | 30L |

ARS-MJQXJ-30LTT | 28KHZ,40KHZ | 1700W | 40L |

ARS-MJQXJ-50LTT | 28KHZ,40KHZ | 2500W | 50L |

ARS-MJQXJ-70LTT | 28KHZ,40KHZ | 3500W | 70L |

ARS-MJQXJ-80LTT | 28KHZ,40KHZ | 4000W | 80L |

ARS-MJQXJ-100LTT | 28KHZ,40KHZ | 5000W | 100L |

ARS-MJQXJ-115LTT | 28KHZ,40KHZ | 5000W | 115L |

ARS-MJQXJ-400LTT | 28KHZ,40KHZ | 6000W | 400L |

40KHZ 80L 4000W Plastic Injection Mold Cleaning For Cleaning Connector Mold

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]