1-49 Sets

$1,850.00

≥50 Sets

$1,750.00

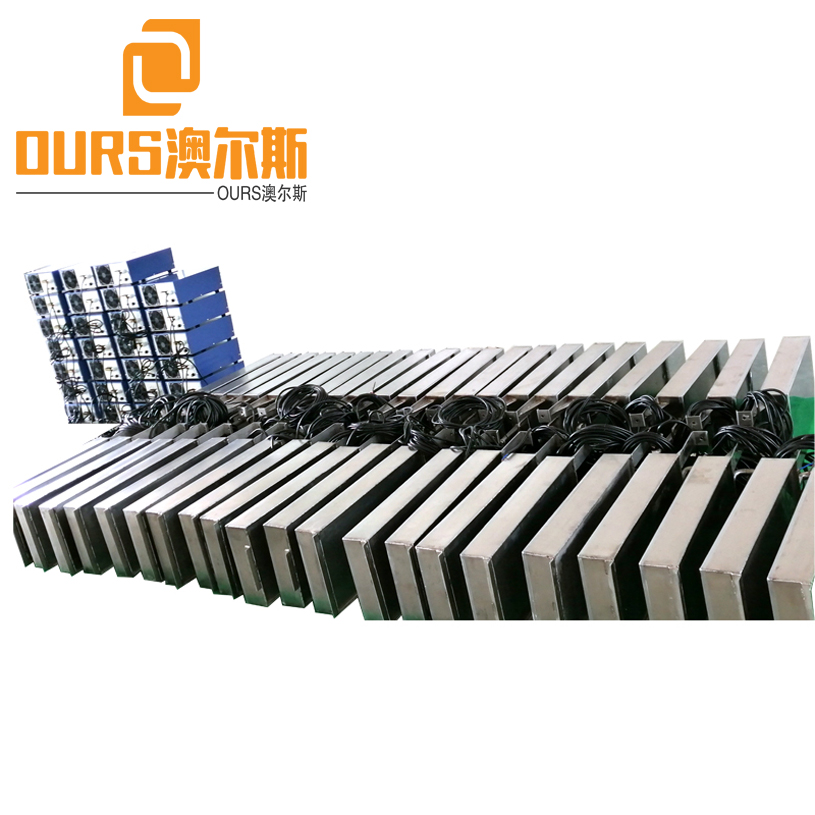

28KHZ 4000W Immersible Ultrasonic Transducer Plate For Ultrasonic Cleaner Engine Parts

The application principle of the ultrasonic vibration plate is that the high-frequency oscillation signal sent by the ultrasonic generator is converted into high-frequency mechanical oscillation by the transducer and transmitted to the medium. The ultrasonic wave in the cleaning solvent radiates forward in the dense and dense phases in the cleaning liquid, so that The flow of liquid produces tens of thousands of tiny bubbles. The tiny bubbles (cavitation nuclei) in the liquid vibrate under the action of the sound field. When the sound pressure reaches a certain value, the bubbles grow rapidly, then suddenly close, and the bubbles close When the shock wave is generated, thousands of atmospheric pressures are generated around it, destroying insoluble dirt and dispersing them in the cleaning liquid. When the group particles are wrapped in oil and adhere to the surface of the cleaning part, the oil is emulsified and the solid particles are Separation, so as to achieve the purpose of cleaning the surface of the cleaning part.

The vibration plate is divided into: input ultrasonic vibration plate, flange type vibration plate and detachable ultrasonic vibration plate. The split structure is adopted, and the high-frequency wire with socket is used for connection between the vibration plate and the ultrasonic generator, which is convenient for use and maintenance.

1. SUS304/SUS316L/titanium plate, strong corrosion-resistant stainless steel plate, waterproof and fully sealed welding.

2.The ultrasonic radiation surface adopts thickened stainless steel plate to extend the life of cavitation corrosion.

3. Unique bonding technology, NTK imported from Japan doubles the life of the transducer. High-Q PZT transducer, stable and strong ultrasonic power is 35% higher than similar products.

4. High-quality coaxial high-frequency ultrasonic signal screen closed line seat, low signal loss, strong anti-interference ability.

5. Advanced ultrasonic technology improves the distribution of energy in the medium, cleans and removes cleaning blind areas, and improves the cleaning effect.

6. Improve and optimize the process flow according to user needs. Provide free process experiment and trial for user needs.

7. According to the needs of users, realize ordinary switch control, PLC weak current control, closed control, remote control, etc.

8. Special specifications, non-standard ultrasonic vibration plates of different sizes, powers and frequencies are customized according to customer requirements.

9. Fully digital ultrasonic generator.

10.Specially designed split ultrasonic generator to adapt to humid and corrosive working environment.

Ultrasonic Immersible Transducer Pack also called the inputting type ultrasonic vibration plates,

1. Use high-strength imported glue and fix the ultrasonic transducer with welding screw to prevent leakage and dampness.

2. Vibrating plate is made of high-quality imported SUS316 2.5mm stainless steel plate. Vibrating surface is made of SUS316L.2.5mm stainless steel with hard chromium plating. Power connection line is protected by SUS304*2M stainless steel soft nozzle. Titanium alloys are used for strong acidic liquid solvents. Overall acid and alkali resistance, beautiful and durable.

3. Using advanced welding technology, laser welding, professional Japanese technicians welding vibration plate

4. One set of free spare parts can be purchased for 30 sets of products of the same specifications at a time.

5. Vibrating plate has no heat, no leakage, low noise, no whistle and low power attenuation.

6. A complete set of schemes can be made according to the specific conditions of customers.

7. Explosion-proof flakes, explosion-proof design, special sensors installed in the vibration plate can detect the changes in the internal environment of the vibration plate and timely feedback to the generator to avoid accidents.

8. Under proper operating conditions, non-man-made damage can be replaced within one year, and the oscillator will not attenuate within two years.

The input type ultrasonic shock plate device consists of shock plate and ultrasonic generator. When the trough type ultrasonic cleaner is not suitable for a specific working environment, the input type shock plate device can be used. For example, in the existing equipment, there is a common cleaning tank, you can add shock plate device, refitted into an ultrasonic cleaning machine. All stainless steel structure, acid and alkali resistance, beautiful and durable. The split structure is adopted, and the high frequency connection with socket between the shock plate and the ultrasonic generator is adopted, which is convenient to use and maintain. The installation and layout are flexible, and can be made into three types: bottom shock type, side shock type and top shock type according to different needs to meet various cleaning requirements.

Scope of application: cleaning electroplated parts before plating, clocks and watches, hardware and machinery parts, polyester filter core, semiconductor silicon, tools, lenses, spectacle frames, jewelry, glassware

Applied areas of electroplating industry: grease, polishing wax and dirt removal.

Pharmaceutical industry: Chinese medicine extraction, bottle cleaning. Optical industry: lens, prism, lens, frame, liquid crystal glass, etc. before and after coating or assembly cleaning.

Machinery industry: oil pump nozzle, engine parts, steam and friction parts, compressor parts, sewing machine parts, metal stamping parts cleaning.

Hardware industry: hardware tools, garden tools, medical equipment cleaning. Other industries: ceramics, tableware, lamps, accessories, crystal, metal pipe cleaning. This product is made of imported high quality stainless steel. The radiant surface of vibration plate has been specially treated, and its service life has been prolonged by more than 50%. It is easy to install, and can be installed at the bottom of the groove to radiate the ultrasonic wave upward, or on the side of the groove or on the liquid surface to emit the ultrasonic wave downward. The specific installation method should be determined according to the shape of the workpiece and the cleaning requirements. The ultrasonic power and the size of the vibration box should be determined according to the volume of the cleaning tank. The general power density should be between 8 and 15KW/m.

Machinery and equipment cleaning advantages:

Good cleaning effect, high cleanliness and uniform cleanliness of all workpieces

_Cleaning speed is fast and production efficiency is improved

_No need to touch the cleaning fluid by hand, and clean the deep holes, slits and hidden parts safely and reliably.

_No damage to workpiece surface

_Save solvents, heat, workplaces and manpower, etc.

Type Description

A.Mounting to tank wall with threaded duct nipple and fastening bracket. Cable through the tank wall.

B.Mounting to tank wall with threaded duct nipple and fixing nipple. Cable through the tank wall.

C.Mounting to tank wall with hanging hooks. Rigid stainless steel tube for cable over the tank top.

D.Mounting to tank wall with hanging hooks. Flexible metal armoured 1 m hose for cable over the tank top.

E.Mounting to tank bottom. Rigid stainless steel tube for cable through the tank wall.

F.Mounting to tank bottom. Rigid stainless steel tube for cable over the tank top.

G.Mounting to tank bottom. Flexible metal armoured 0,5 m hose for cable through the tank wall.

H. Mounting to tank bottom. Flexible metal armoured 1,5 m hose for cable over the tank top.

X.Non-standard mounting

Type | Diamention(mm) | Frequency (Khz) | Power(W) | Ultrasonic Transducer |

ARS-ZBH300W | 300*190*100 | 25,28,33,40,80,130 | 300 | 6 |

ARS-ZBH600W | 360*275*100 | 25,28,33,40,80,130 | 600 | 12 |

ARS-ZBH1000W | 450*350*100 | 25,28,33,40,80,130 | 1000 | 20 |

ARS-ZBH1200W | 470*380*100 | 25,28,33,40,80,130 | 1200 | 24 |

ARS-ZBH1500W | 520*450*100 | 25,28,33,40,80,130 | 1500 | 30 |

ARS-ZBH1800W | 560*450*100 | 25,28,33,40,80,130 | 1800 | 36 |

ARS-ZBH2000W | 650*450*100 | 25,28,33,40,80,130 | 2000 | 40 |

ARS-ZBH2400W | 740*520*100 | 25,28,33,40,80,130 | 2400 | 48 |

ARS-ZBH3000W | 820*540*100 | 25,28,33,40,80,130 | 3000 | 60 |

ARS-ZBH5000W | 1200*590*100 | 25,28,33,40,80,130 | 5000 | 100 |

Above are single frequency ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power) | ||||

28KHZ 4000W Immersible Ultrasonic Transducer Plate For Ultrasonic Cleaner Engine Parts

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]