1-9 Sets

$9,850.00

≥10 Sets

$9,650.00

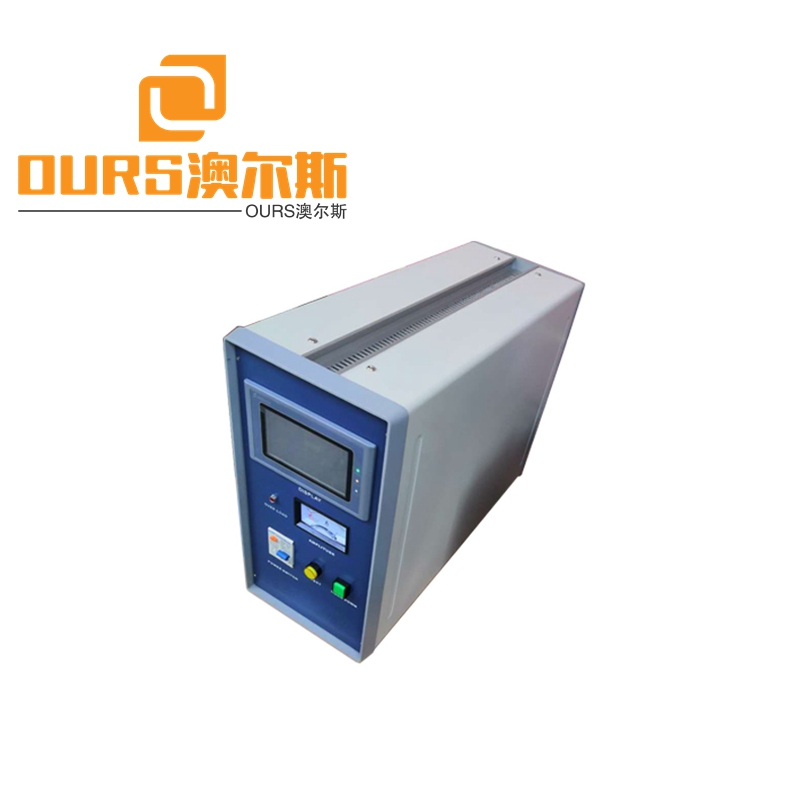

35KHZ 1000W High Frequency Ultrasonic Metal Welding Machine For Welding Copper Plate

![]()

Ultrasonic metal welding machine: It is similar to friction welding, but there are differences. Ultrasonic welding takes a short time and the temperature is lower than recrystallization; it is also different from pressure welding because the static pressure applied is much smaller than that of pressure welding. It is generally believed that in the initial stage of the ultrasonic welding process, the tangential vibration removes the oxides on the metal surface, and the protruding part of the rough surface produces repeated micro-welding and destruction, which increases the contact area and increases the temperature of the welding zone. High, plastic deformation occurs at the interface of the weldment. In this way, under the action of contact pressure, when they approach each other to the distance at which atomic gravity can act, a solder joint is formed. The welding time is too long, or the ultrasonic amplitude is too large, which will reduce the welding strength or even destroy it. Ultrasonic metal welding machine is an advanced high-tech equipment that converts high-frequency electric energy into mechanical vibration energy through a transducer and acts on the workpiece, generating high-frequency friction between the surfaces of the two workpieces, until the surfaces of the two workpieces are heated and welded together . It can perform spot and strip welding on thin materials of conductive metals such as copper, silver, chromium-nickel, etc. It can be widely used in thyristor chip leads, fast fuse melt sockets, electrical lead terminals, lithium ion, nickel Point and strip welding of pole pieces and tabs of hydrogen and nickel-cadmium batteries.

Features of Ultrasonic Metal Welding Machine

1. The two objects to be welded are overlapped and joined by ultrasonic vibration and pressure to form a solid state, the joining time is short, and the joining part does not produce cast structure (rough surface) defects.

2. Compared with the method of ultrasonic welding and resistance welding, the mold life is long, the mold repair and replacement time is less, and it is easy to realize automation.

3. Ultrasonic welding can be carried out between the same metal and different metals, which consumes much less energy than electric welding.

4. Compared with other pressure welding, ultrasonic welding requires less pressure, and the deformation amount is less than 10%, while the deformation of the workpiece in cold pressure welding is 40%-90%.

5. Ultrasonic welding does not require pre-treatment of the welded surface and post-weld post-treatment like other welding.

6. There is no need for external factors such as flux, metal filler, and external heating to handle ultrasonic welding.

Type | Power(W) | Frequency (KHz) |

ARS-JSHJ-800W35 | 800W | 35KHz |

ARS-JSHJ-800W40 | 800W | 40KHz |

ARS-JSHJ-1000W15 | 1000W | 15KHz |

ARS-SLHJ-1000W20 | 1000W | 20KHz |

ARS-SLHJ-1000W35 | 1000W | 35KHz |

ARS-SLHJ-1000W40 | 1000W | 40KHZ |

ARS-JSHJ-2000W20 | 2000W | 20KHZ |

ARS-JSHJ-2000W15 | 2000W | 15KHZ |

ARS-JSHJ-3200W15 | 3200W | 15KHZ |

ARS-JSHJ-4200W15 | 4200W | 15KHZ |

![]()

35KHZ 1000W High Frequency Ultrasonic Metal Welding Machine For Welding Copper Plate

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]