50-4999 Pieces

$6.50

≥5000 Pieces

$5.50

50*20*6mm High Stability Piezo Ceramic Ring For Ultrasonic Pressure sensor

![]() Piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

Piezoelectric ceramic,Piezoelectric ceramic for transducer,Piezoelectric ceramic for cleaner,piezo ceramic,Tube Piezoelectric ceramic,Disc piezoelectric ceramic, Rectangle Piezoceramic, Cube Piezo ceramic, hemisphere piezo ceramic,Halfsphere Piezo ceramic, Semisphere piezo ceramic,Ball Piezo ceramic,Piezo ceramic for tooth cleaning,piezo ceramic for boat,piezo ceramic for medical,piezo ceramic for follow meter

Ring piezoelectric ceramics make use of the characteristics of piezoelectric ceramics to convert external force into electrical energy, which can produce piezoelectric igniter, mobile X-ray power supply, projectile detonation device. Using two piezoelectric ceramic pillars 3 mm in diameter and 5 mm in height instead of ordinary flint, a gas electronic lighter can be made that can be continuously lighted tens of thousands of times. Using piezoelectric ceramics to convert electrical energy into ultrasonic vibration can be used to explore the position and shape of underwater fish, non-destructive metal detection, ultrasonic cleaning, ultrasonic medical treatment, can also be made into a variety of ultrasonic cutters, welding devices and soldering iron, plastic and even metal processing.

Piezoceramic components, such as plates, disks or rings, convert mechanical signals, such as force, pressure, strain or acceleration, into electrical voltage, or, vice versa, an electrical voltage into mechanical motion or oscillations. The typical resonant frequencies are between 200 kHz and 10 MHz. The shapes and dimensions of the piezo components can be selected within the limits determined by the tools, although the dimensions depend on each other. The minimum dimensions are determined by physical and technological limits. The thickness or wall thickness, for example, is limited by the mechanical strength of the ceramic during machining. In the polarization direction, the dimension is at most 30 mm.

Piezoelectric ceramic wafer is a simple and lightweight electrical device. It is widely used because of its high sensitivity, no magnetic field spreading, no copper wire and magnet, low cost, low power consumption, and easy mass production. Suitable for the transmission and reception of ultrasonic and infrasonic waves, a relatively large area of piezoelectric ceramics can also be used to detect pressure and vibration. The working principle is to use the reversibility of the piezoelectric effect to apply audio voltage on it to emit sound.

Piezoelectric ceramics are functional ceramic materials that can mutually convert mechanical energy and electrical energy, and belong to inorganic non-metallic materials. At the same time, it has positive and negative piezoelectric effects. The piezoelectric ceramic wafers I produce are mainly used in ultrasonic probes, ultrasonic medical treatment, ultrasonic flow meters, automatic control and other fields. With outstanding performance and complete specifications, PZT piezoelectric wafers and new composite piezoelectric wafers can meet different types of needs.

Piezoelectric ceramics are widely used in our daily production and life. The first choice for piezoelectric ceramics production is to choose a professional manufacturer with a piezoelectric ceramic R&D team, which can be customized according to the customer's special needs for piezoelectric ceramics.

PiezoelectricCeramics (PZT) materials are categorized as functional ceramics. In sensors they make it possible toconvert forces, pressures and accelerations into electrical signals, and in sonic and ultrasonic transducers and actuators they convert electric voltages into vibrations or deformations.PiezoelectricCeramics materials are classified according to their chemical composition on the one hand, and by the specific application conditions on the other.

In response to change in temperature, it is the change in electrical response polarization state due to the tendency of some materials. As a response to temperature shifts, a voltage will arise between the electrodes on the two surfaces if the materials.

Application

1. ultrasonic cleaning trasnducer

2. ultrasonic welding tansducer

3. ultrasonic beauty transducer

4. ultrasonic underwater transducer

5. ultrasonic immersible transucer

6. ultrasonic screening transducer

7. ultrasonic cutting transducer

8. ultrasonic atomization transducer

9. ultrasonic emulsifier

![]()

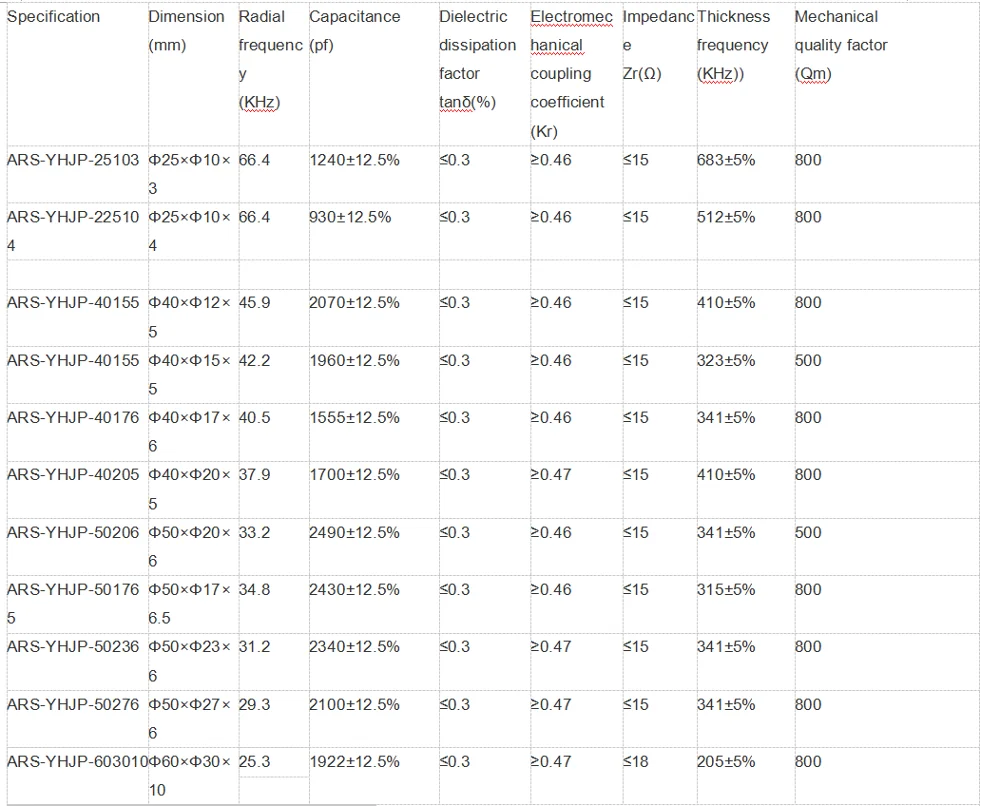

50*20*6mm High Stability Piezo Ceramic Ring For Ultrasonic Pressure sensor

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]