30Khz High Efficiency Ultrasonic Welding Car Wheel Cover Guard Handheld Welding Machine

1-9 Sets

$850.00

≥10 Sets

$820.00

Model Number

ARS-DHJ-90030

description

30Khz High Efficiency Ultrasonic Welding Car Wheel Cover Guard Handheld Welding Machine

![]()

Ultrasonic spot welding machine is divided into: ultrasonic spot welding machine, ultrasonic plastic spot welding machine, riveting spot welding machine, ultrasonic metal welding machine, ultrasonic metal spot welding machine, ultrasonic welding machine, aluminum nickel welding machine, polymer battery positive electrode spot welding machine , Lithium battery negative spot welder, aluminum to nickel spot welder, amorphous silicon spot welder, etc.

The welding principle of ultrasonic spot welder is to convert 50/60 Hz current into 15, 20, 30 or 40 kHz electric energy through ultrasonic generator. The converted high-frequency electric energy is converted into mechanical motion of the same frequency again through the transducer, and then the mechanical motion is transmitted to the welding head through a set of amplitude modulator devices that can change the amplitude. The welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, the vibration energy is converted into thermal energy by friction to melt the plastic. The short-term pressure maintained on the workpiece after the vibration stops causes the two weldments to solidify in a molecularly linked manner. Generally, the welding time is less than 1 second, and the obtained welding strength is comparable to the body. Ultrasound can be used not only to weld rigid thermoplastics, but also to fabrics and films. The main components of an ultrasonic welding system include an ultrasonic generator, a transducer / amplifier / welding head triplet, a mold and a frame.

The welding principle of ultrasonic spot welder is to convert 50/60 Hz current into 15, 20, 30 or 40 kHz electric energy through ultrasonic generator. The converted high-frequency electric energy is converted into mechanical motion of the same frequency again through the transducer, and then the mechanical motion is transmitted to the welding head through a set of amplitude modulator devices that can change the amplitude. The welding head transmits the received vibration energy to the joint of the workpiece to be welded. In this area, the vibration energy is converted into thermal energy by friction to melt the plastic. The short-term pressure maintained on the workpiece after the vibration stops causes the two weldments to solidify in a molecularly linked manner. Generally, the welding time is less than 1 second, and the obtained welding strength is comparable to the body. Ultrasound can be used not only to weld rigid thermoplastics, but also to fabrics and films. The main components of an ultrasonic welding system include an ultrasonic generator, a transducer / amplifier / welding head triplet, a mold and a frame.

Ultrasonic spot welding in the plastics thermoplastics and structural foam materials

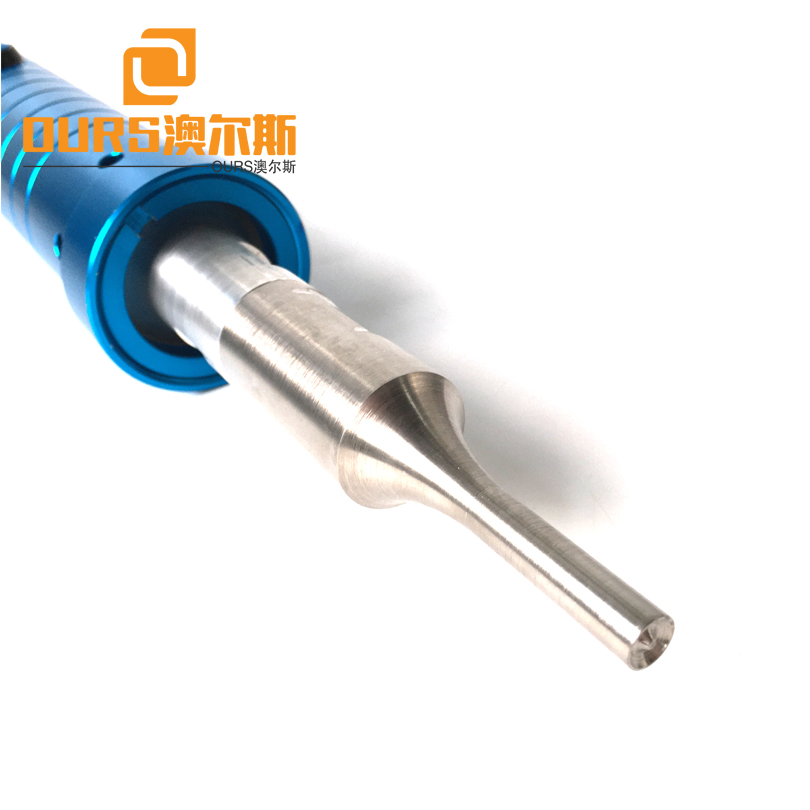

The hand-held sonotrode for ultrasonic welding (bonding) is light and handy, suitable for left- or right-handed operation. It is equipped with simple air-cooling system, which prevents the device from heating and the palm from sweating and this way facilitates the control and precise operation.

The ultrasonic hand-held sonotrode is equipped with an ultrasonic generator type. The horn and the handle are made of high—quality materials, that ensure long life and smooth operation.

Basic characteristics:

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

The hand-held sonotrode for ultrasonic welding (bonding) is light and handy, suitable for left- or right-handed operation. It is equipped with simple air-cooling system, which prevents the device from heating and the palm from sweating and this way facilitates the control and precise operation.

The ultrasonic hand-held sonotrode is equipped with an ultrasonic generator type. The horn and the handle are made of high—quality materials, that ensure long life and smooth operation.

Basic characteristics:

Speed of welding: approximately 5 seconds, depending on the material and the required results.

The ultrasonic technology ensures strong and high-quality welding between the assembled parts without using additional materials.

Machine use:

Ultrasonic plastic welding machine is suitable for ultrasonic welding of a variety of plastic materials such as ABS, PE, PC, PS, PVC, PP, ABS and PC composites, and acrylic. Such as: laptop battery, mobile phone battery shell, computer power adapter, mobile phone charger, shell, U disk, SD card, USB connector, folder and other products

Machine characteristics:

Frequency modulation and frequency automatic compensation circuit, digital welding parameter setting, intuitive and accurate;

Japan's original piezoelectric ceramic transducer output is strong and stable, and the trump steel luffing rod is durable;

CNC machined spherical vibrator holder, fine adjustment of fine screw level, higher level adjustment precision; CNC machine tool processing, high precision; soft start circuit to avoid damage to the mold.

Compared with traditional processes (such as gluing, electric welding or screw fastening), the handheld ultrasonic spot welding machine has the significant advantages of high production efficiency, good welding quality, environmental protection and energy saving. The handheld ultrasonic welding machine can also be used for welding and riveting of thermoplastic products, as well as inlaying and blanking processes between metal and plastic parts. It has completely replaced the process of pasting organic melting point, and has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, solid welding, and convenient operation. Ultrasonic waves can be used not only for welding metals, rigid thermoplastics, but also for fabrics and films. The hand-held ultrasonic welding machine can replace different ultrasonic welding heads according to the size of the riveting point of the product to be welded and the welding requirements. It is fast and convenient, and the cost is much lower than that of a special automotive door plate ultrasonic welding machine, which meets customer needs. .

Ultrasonic plastic welding machine is suitable for ultrasonic welding of a variety of plastic materials such as ABS, PE, PC, PS, PVC, PP, ABS and PC composites, and acrylic. Such as: laptop battery, mobile phone battery shell, computer power adapter, mobile phone charger, shell, U disk, SD card, USB connector, folder and other products

Machine characteristics:

Frequency modulation and frequency automatic compensation circuit, digital welding parameter setting, intuitive and accurate;

Japan's original piezoelectric ceramic transducer output is strong and stable, and the trump steel luffing rod is durable;

CNC machined spherical vibrator holder, fine adjustment of fine screw level, higher level adjustment precision; CNC machine tool processing, high precision; soft start circuit to avoid damage to the mold.

Compared with traditional processes (such as gluing, electric welding or screw fastening), the handheld ultrasonic spot welding machine has the significant advantages of high production efficiency, good welding quality, environmental protection and energy saving. The handheld ultrasonic welding machine can also be used for welding and riveting of thermoplastic products, as well as inlaying and blanking processes between metal and plastic parts. It has completely replaced the process of pasting organic melting point, and has the characteristics of low energy consumption, high efficiency, no deformation, no pollution, solid welding, and convenient operation. Ultrasonic waves can be used not only for welding metals, rigid thermoplastics, but also for fabrics and films. The hand-held ultrasonic welding machine can replace different ultrasonic welding heads according to the size of the riveting point of the product to be welded and the welding requirements. It is fast and convenient, and the cost is much lower than that of a special automotive door plate ultrasonic welding machine, which meets customer needs. .

Product Specifications :

1 - hand welder can be applied to a single point welding, screw implants , riveting .

2 - Portable design , save space , easy to operate.

3 - can be used independently , but also can be used with automatic peripheral equipment .

4 - There are lessons device models , especially for rhinestones / PC drill mount in haute couture processing .

Specifications

1. ultrasonic generator + ultrasonic transducer+ horn.

ultrasonic welding machine for plastic

1.PP,ABS,AS,PS,nylon welding

2.high power and strong

3.good quality with best price

Ultrasonic welding machine for plastic remains one of the fastest techniques for welding smaller thermoplastic parts. In ultrasonic welding, one part is held stationary in a holding fixture while the other part is vibrated acoustically against it under pressure, creating frictional heat at their joining surfaces.

Applications:

Ultrasonic welding machine for plastic is widely used in auto industry, electron industry, medical treatment industry, office supply, packaging industry, and toy industry, etc. For example,

Ultrasonicspotwelding machine

Type | Power(W) | Frequency (KHz) |

ARS-DHJ-300 | 300W | 15khz |

ARS-DHJ-300 | 300W | 20khz |

ARS-DHJ-300 | 300W | 28khz |

ARS-DHJ-300 | 300W | 35KHz |

ARS-DHJ-300 | 300W | 40khz |

ARS-DHJ-500 | 500W | 15khz |

ARS-DHJ-500 | 500W | 20khz |

ARS-DHJ-500 | 500W | 28khz |

ARS-DHJ-500 | 500W | 35KHz |

ARS-DHJ-500 | 500W | 40khz |

ARS-DHJ-800 | 800W | 15khz |

ARS-DHJ-800 | 800W | 20khz |

ARS-DHJ-800 | 800W | 28khz |

ARS-DHJ-800 | 800W | 35KHz |

ARS-DHJ-800 | 800W | 40khz |

ARS-DHJ-900 | 900W | 15KHz |

ARS-DHJ-900 | 900W | 20khz |

ARS-DHJ-1000 | 1000W | 15KHz |

ARS-DHJ-1000 | 1000W | 20khz |

![]()

30Khz High Efficiency Ultrasonic Welding Car Wheel Cover Guard Handheld Welding Machine

Have more questions about this product?

Scan the QR code with your phone, or visit the URL

Have more questions about this product?

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]