1-999 Pieces

$15.00

≥1000 Pieces

$14.00

Factory Production 120KHZ 60W High Frequency Different Types Ultrasound Transducers For Ultrasonic Cleaning

High frequencies are often used to clean smaller, more delicate parts, or to remove small particles. High frequencies are also used in applications where damage to the surface of the workpiece is not allowed. The use of high frequencies can improve cleaning performance in several ways. As the frequency increases, the number of cavitation bubbles increases linearly, resulting in more and more dense shock waves that allow them to enter smaller gaps. If the power remains the same, the cavitation bubble becomes smaller, and the energy it releases is correspondingly reduced, which effectively reduces the damage to the surface of the workpiece. Another advantage of high-frequency is that it reduces the viscous boundary layer (Ponnuri effect), allowing ultrasound to 'find' very small particles. And our high-frequency ultrasonic oscillators also have 68KHZ, 80KHZ, 100KHZ, 120KHZ.

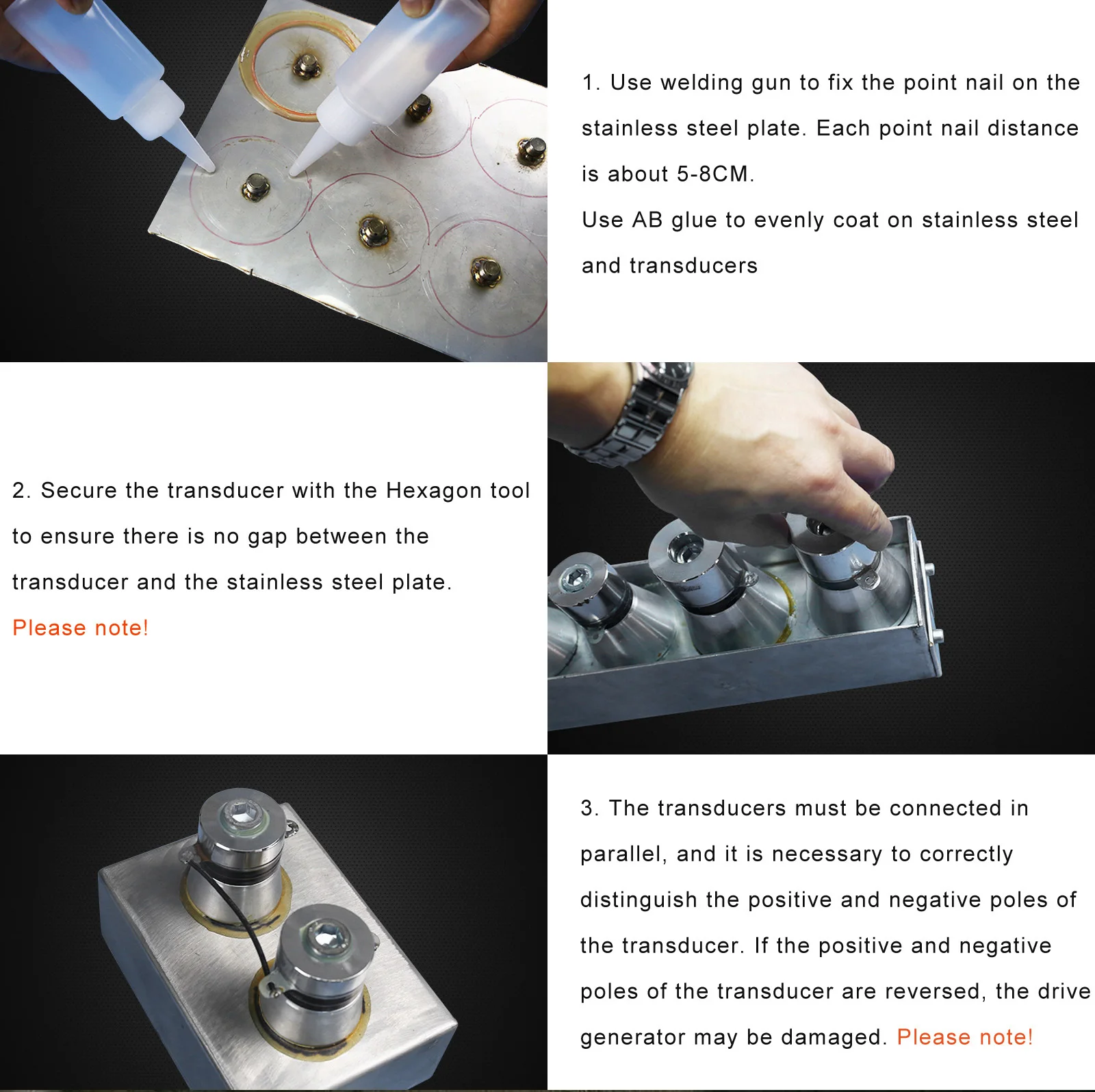

To install an ultrasonic oscillator, you must first understand the structure of the ultrasonic oscillator and the working principle of the ultrasonic oscillator. In fact, the ultrasonic oscillator is also called an ultrasonic oscillator.

The ultrasonic vibrator is a device that realizes the mutual conversion of electrical energy and mechanical energy (acoustic vibration) by the piezoelectric effect of piezoelectric ceramics, and amplifies the acoustic impedance matching front and rear radiation cover blocks. The ultrasonic vibrator is composed of an ultrasonic transducer and an ultrasonic horn. The ultrasonic transducer is a device that can convert high-frequency electrical energy into mechanical energy. The ultrasonic horn is a passive device that does not generate vibration itself. It only transmits the amplitude of the vibration input by the ultrasonic transducer before changing it. Impedance transformation.

The mechanism of ultrasonic cleaning is to make use of the physical effects such as cavitation, radiation pressure and sound flow in the cleaning liquid. It can exfoliate the machinery produced by the dirt on the cleaning parts, and can also promote the chemical reaction between the cleaning liquid and the dirt, so as to achieve the purpose of cleaning the object. The frequency of the ultrasonic cleaning machine can be selected by 10~500 kHz according to the size and purpose of the cleaning material, generally more than 20~50 kHz. With the increase of the frequency of ultrasonic transducer, Langerhans oscillator, longitudinal oscillator and thickness oscillator can be used. In the miniaturization aspect, radial vibration and flexural vibration are also adopted. Ultrasonic cleaning has become more and more widely used in various industries, agriculture, household equipment, electronics, automobile, rubber, printing, aircraft, food, hospital and medical research.

The transducer uses different piezoelectric materials to explain that:

The black chip is P4 series, which is a medium power emitting material with dual transmitting and receiving characteristics.

With low dielectric loss and high mechanical quality factor, it is mainly used in ultrasonic cleaning, ultrasonic atomization and so on.

The Yellow chip is P8 series, which is a high-power emission material with high mechanical quality factor.

Good stability, very low dielectric loss, especially suitable for making high-power ultrasonic transducers. Widely used in

Ultrasonic welding, ultrasonic emulsification, ultrasonic polishing, ultrasonic cleaning and so on.

Main Features:

- High Q value.

- Large amplitude.

- High conversion frequency, low heat.

- Output is stable.

- Strict quality control.

1.High efficiency : high quality mechine, high electro-acoustic conversion efficiency at the resonant frequencies.

2.Large amplitude : computer optimized structure, high vibration ratio , large amplitude front cover.

3.High power: In the influence of pre-stressed screw, piezoelectric ceramic energy can achieve to the most.

4.Heat-resistance: small resonant impedance, wide temperature range.

| Specification List | ||||

| Model | Frequency | Capacitance | Size | Power |

| (KHz) | (pF) | Radiation head*Height (mm) | (W) | |

| ARS-4QXHNQ-17K60W | 17±0.5 | 4800±10% | 78*90 | 60w |

| ARS-4QXHNQ-20K50W | 20±0.5 | 4000±10% | 57*94 | 50w |

| ARS-8QXHNQ-20K70W | 20±0.5 | 3250±10% | 78*94 | 70w |

| ARS-4QXHNQ-20K100W | 20±0.5 | 7600±10% | 67*92 | 100w |

| ARS-8QXHNQ-20K100W | 20±0.5 | 4500±10% | 67*92 | 100w |

| ARS-8QXHNQ-20K120W | 20±0.5 | 4650±10% | 79*94 | 120w |

| ARS-4QXHNQ-25K60W | 25±0.8 | 4800±10% | 59*80 | 60w |

| ARS-4QXHNQ-25K100W | 25±0.5 | 7600±10% | 67*76 | 100w |

| ARS-4QXHNQ-28K50WN | 28 ±0.5 | 4000±10% | 45*79 | 50w |

| ARS-4QXHNQ-28K60W | 28±0.5 | 4800±10% | 59*68 | 60w |

| ARS-4QXHNQ-28K100W | 28±0.5 | 7600±10% | 67*68 | 100w |

| ARS-8QXHNQ-28K100W | 28±0.5 | 5800±10% | 67*68 | 100w |

| ARS-4QXHNQ-28K120W | 28±0.5 | 9600±10% | 67*68 | 120w |

| ARS-8QXHNQ-28K120W | 28±0.5 | 6500±10% | 67*68 | 120w |

| ARS-4QXHNQ-33K60W | 33±0.5 | 4800±10% | 48*62 | 60w |

| ARS-8QXHNQ-33K60W | 33±0.5 | 3750±10% | 48*62 | 60w |

| ARS-4QXHNQ-35K60W | 35±0.5 | 4800±10% | 45*55 | 60w |

| ARS-4QXHNQ-40K30W | 40±0.8 | 2400±10% | 30*50 | 30w |

| ARS-4QXHNQ-40K50W | 40 ±1.0 | 4000±10% | 45*55 | 50w |

| ARS-4QXHNQ-40K50WN | 40 ±1.0 | 4000±10% | 45*53 | 50w |

| ARS-8QXHNQ-40K50WN | 40 ±1.0 | 3250±10% | 45*53 | 50w |

| ARS-4QXHNQ-40K60W | 40±0.5 | 4800±10% | 48*52 | 60w |

| ARS-8QXHNQ-40K60WN | 40±0.5 | 3850±10% | 48*50 | 60w |

| ARS-4QXHNQ-40K100W | 40±0.5 | 7600±10% | 55*53 | 100w |

| ARS-4QXHNQ-48K50W | 48±0.5 | 4000±10% | 35*34.5 | 50W |

| ARS-4QXHNQ-54K35W | 54±1.0 | 3100±10% | 30*42 | 35w |

| ARS-4QXHNQ-60K20W | 60±1.5 | 2300±10% | 30*35 | 20w |

| ARS-4QXHNQ-68K30W | 68±1.5 | 2300±10% | 25*31 | 30w |

| ARS-4QXHNQ-68K50W | 68±2.0 | 4800±10% | 50*65 | 50w |

| ARS-4QXHNQ-70K60W | 70±2.0 | 4800±10% | 50*65 | 60W |

| ARS-4QXHNQ-80K60W | 80±1.5 | 4800±10% | 40*54 | 60w |

| ARS-4QXHNQ-100K60W | 100±1.5 | 4800±10% | 40*57 | 60w |

| ARS-4QXHNQ-120K60W | 120±1.5 | 4800±10% | 40*58 | 60w |

| ARS-4QXHNQ-130K50W | 130±1.5 | 4200±10% | 36*54 | 50w |

| ARS-4QXHNQ-135K50W | 135±1.5 | 4200±10% | 36*54 | 50w |

| ARS-4QXHNQ-160K50W | 160±1.5 | 4800±10% | 40*57 | 60w |

| ARS-4QXHNQ-165K40W | 165±5.0 | 4100±10% | 42*61 | 40w |

| ARS-4QXHNQ-200K20W | 200±2.0 | 2300±10% | 30*35 | 20w |

| ARS-8QXHNQ-28K/40K60W | 28/40±1.0 | 3800±10% | 65*70 | 60w |

| ARS-8QXHNQ-40K/130K20W | 40/130±2.0 | 3100±10% | 25*58 | 20w |

| ARS-4QXHNQ-40K/68K50W | 38/66±2.0 | 4800±10% | 50*65 | 50w |

| ARS-4QXHNQ-40K/80K/130K60W | 40/80/130±2.0 | 4200±10% | 40*54 | 60w |

| ARS-4QXHNQ-40/60/8060 | 38/65/84±2.0 | 4800±10% | 40*54 | 60w |

| ARS-8QXHNQ-20K/40K/60K120W | 20/40/60±2.0 | 5200±10% | 78*94 | 120w |

| ARS-4QXHNQ-40K/100K/160K60W | 40/100/160±2.0 | 4800±10% | 40*57 | 60w |

| Screw hole size (diameter * pitch * depth)M10*1.0*10 | ||||

Factory Production 120KHZ 60W High Frequency Different Types Ultrasound Transducers For Ultrasonic Cleaning

Scan the QR code with your phone, or visit the URL

- 506B,Dazhong industry park,sanhe ,DaLang street,longhua district,ShenZhen China

- 86-13662219669

- [email protected]