Factory Sales 40khz Ultrasound Transducer For Household Ultrasonic Cleaner

1-499 Piece

$6.50

≥ 500 Piece

$6.00

- Item No.20201104055feMOQ1 Piece

- Product size20 x 15 x 15 mProduct weight2 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

Factory Sales 40khz Ultrasound Transducer For Household Ultrasonic Cleaner

The mechanism of ultrasonic cleaning is to make use of the physical effects such as cavitation, radiation pressure and sound flow in the cleaning liquid. It can exfoliate the machinery produced by the dirt on the cleaning parts, and can also promote the chemical reaction between the cleaning liquid and the dirt, so as to achieve the purpose of cleaning the object. The frequency of the ultrasonic cleaning machine can be selected by 10~500 kHz according to the size and purpose of the cleaning material, generally more than 20~50 kHz. With the increase of the frequency of ultrasonic transducer, Langerhans oscillator, longitudinal oscillator and thickness oscillator can be used. In the miniaturization aspect, radial vibration and flexural vibration are also adopted. Ultrasonic cleaning has become more and more widely used in various industries, agriculture, household equipment, electronics, automobile, rubber, printing, aircraft, food, hospital and medical research.

Principle of ultrasonic vibrator arrangement:

(1) Cleaning different product layouts have different requirements, such as the degree of oil staining of the product, the difficulty of cleaning, the level of cleaning requirements, and the design of the cleaning process, all require targeted selection.

(2) The arrangement of the vibrators is not as dense as possible, and the right one is the best.

3. Introduction to ultrasonic vibrator:

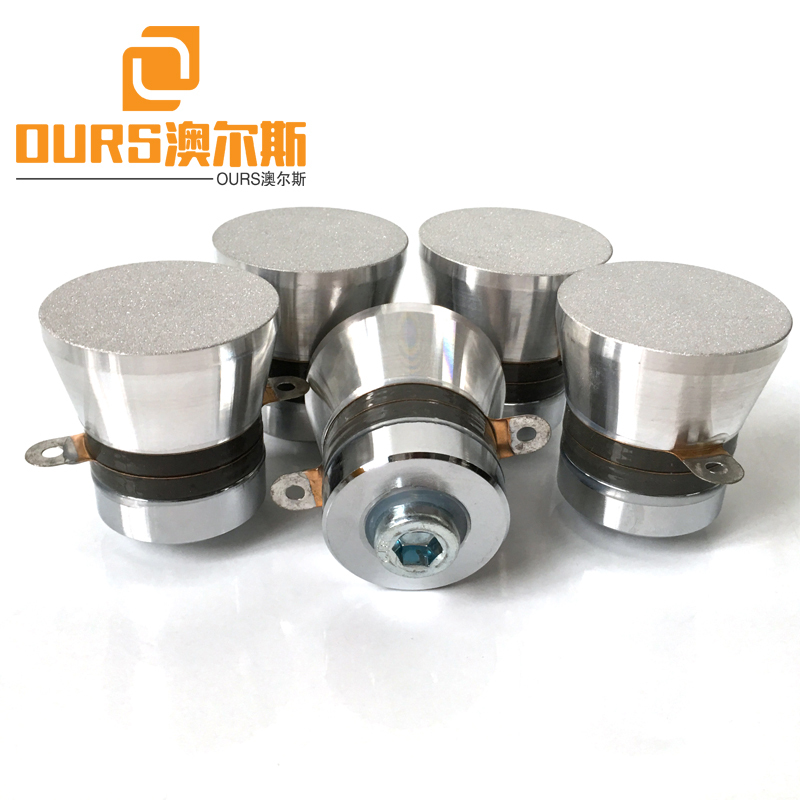

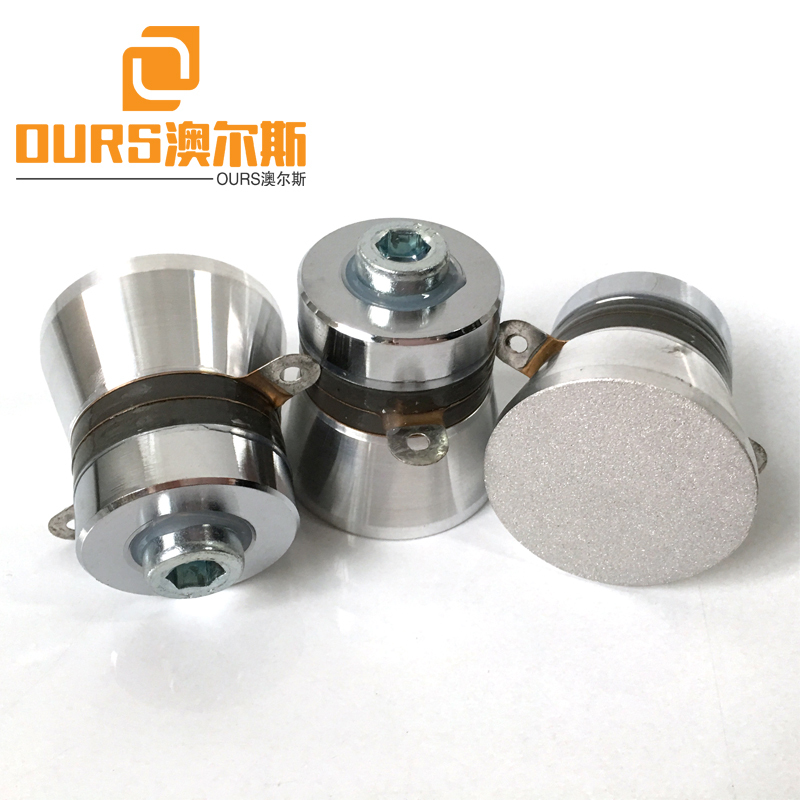

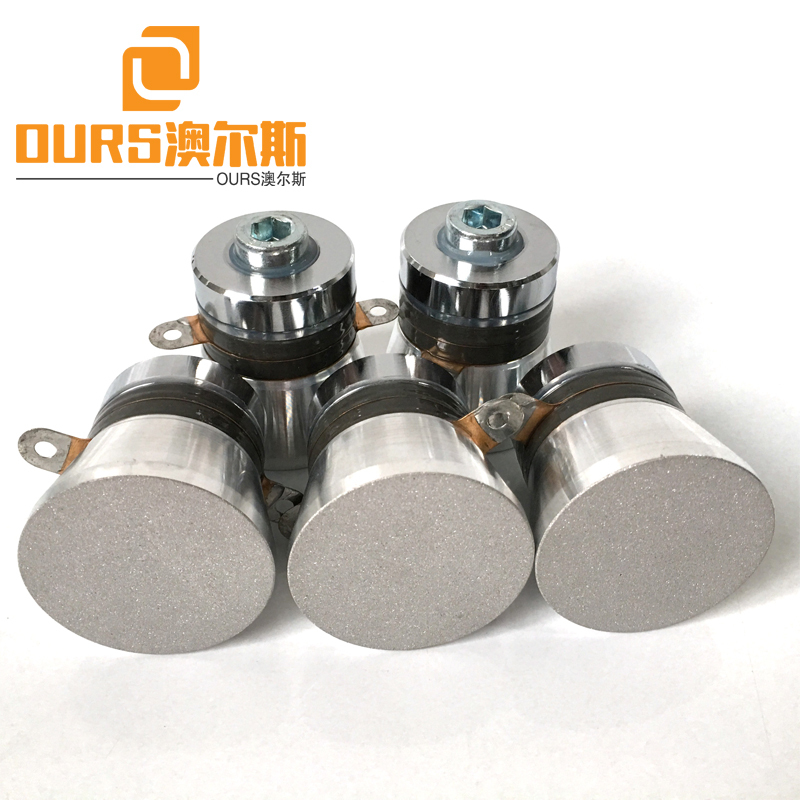

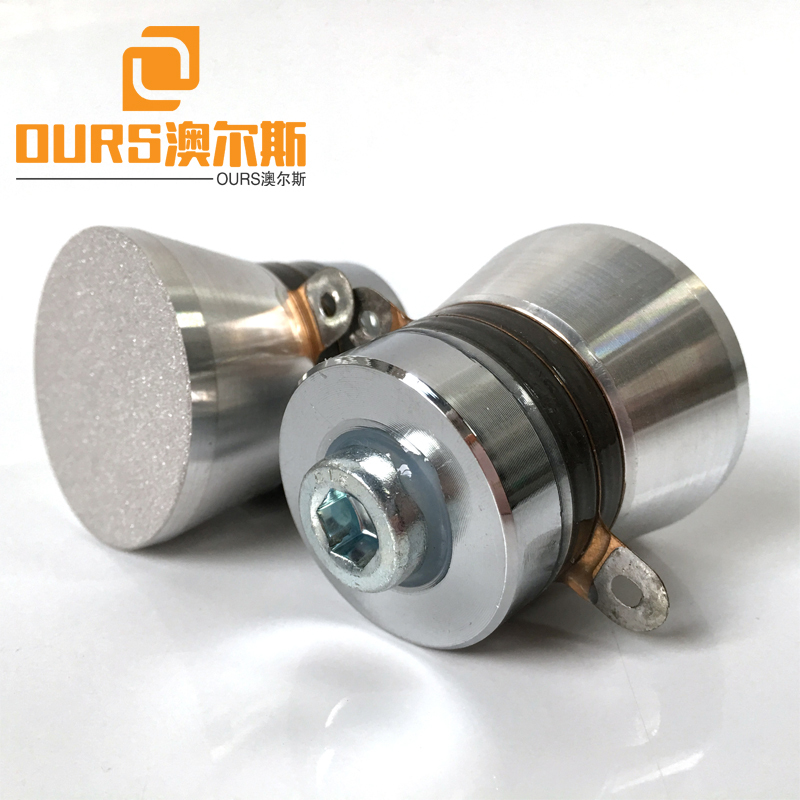

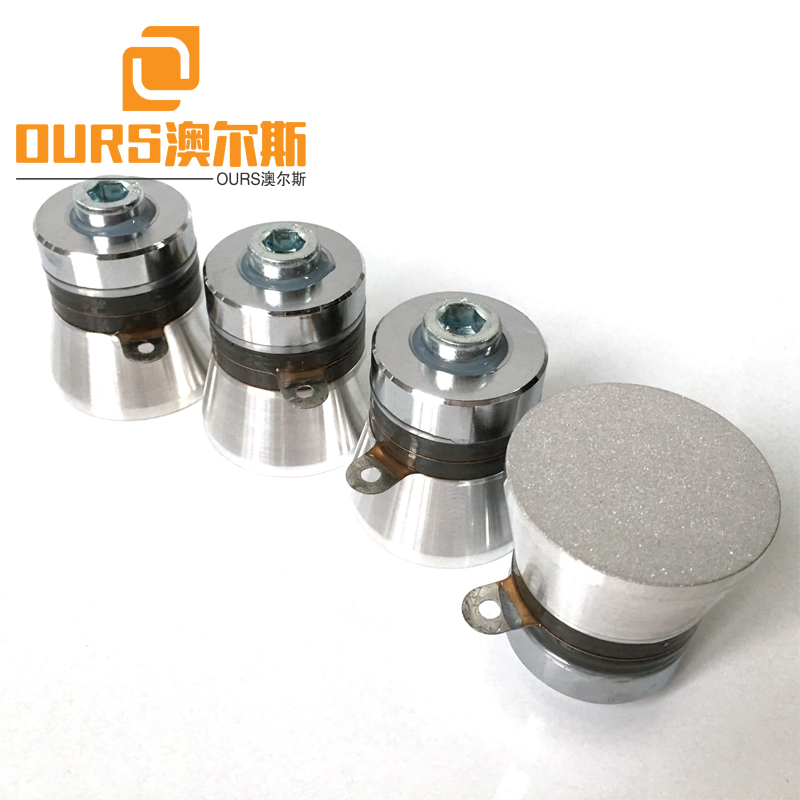

The ultrasonic vibrator, also called the ultrasonic vibrating head, is an ultrasonic transducer and is a core component of the ultrasonic cleaning machine. Industry standard name: Ultrasonic transducer, which belongs to piezoelectric ceramic material and one of the main accessories of ultrasonic cleaning machine. From the power point, a single ultrasonic head is 60W, 100W. The frequencies are: 20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher; the difference in shape is: straight cylindrical shape, horn shape, and the like.

Ultrasonic oscillator principle:

1. The piezoelectric element and the internal electrode are alternately stacked in the ultrasonic vibrator, and have an external electrode that is electrically connected to the internal electrode;

The ultrasonic transducer includes an internal electrode group that is substantially divided into four portions along a second direction and a third direction orthogonal to a lamination direction as the first direction, and a first external electrode group and a second external electrode group respectively The electrode group is turned on; by applying an alternating voltage to the first external electrode group and the second external electrode group, the longitudinal vibration mode in which the main vibration occurs in the second direction and the main vibration are in the third direction a bending vibration mode that occurs, thereby generating ultrasonic elliptical vibration;

The ultrasonic transducer includes a conductor film for electrode connection formed along a surface perpendicular to the stacking direction, and predetermined predetermined external electrodes of the first external electrode group and the second external electrode group The external electrodes are electrically connected. A device that converts electrical energy and acoustic energy by piezoelectric effect is called a piezoelectric transducer. The ultrasonic transducer provided by the company uses self-produced high-quality piezoelectric ceramic components, which are carefully designed, processed and tested to be bolts. The fastening type produces stable ultrasonic waves even when the load changes. It has the characteristics of large amplitude, high electroacoustic conversion rate, low heat generation, high reliability and good consistency.

A transducer is a device used to perform energy conversion, and is a device that converts one form of energy into another form of energy. In the field of acoustics research, transducers mainly refer to electroacoustic transducers, which can convert between electrical and acoustic energy.

Acoustic transducers have sharp directivity, which is conducive to concentrated transmission energy, can obtain a higher signal-to-noise ratio during reception, and is also conducive to the evaluation of the positioning of detection targets. Ultrasonic welding machine manufacturers indicate that the ultrasonic transducer is related to its radiation surface size, structure, operating frequency, and characteristics of the sound transmitting medium. Most of them can use the directivity factor to reflect the directivity of the ultrasonic transducer.

Factory Sales 40khz Ultrasound Transducer For Household Ultrasonic Cleaner

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian