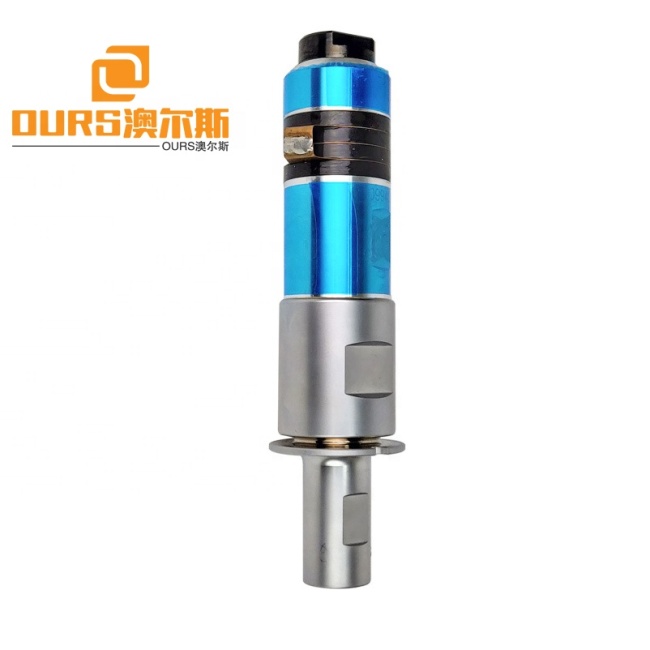

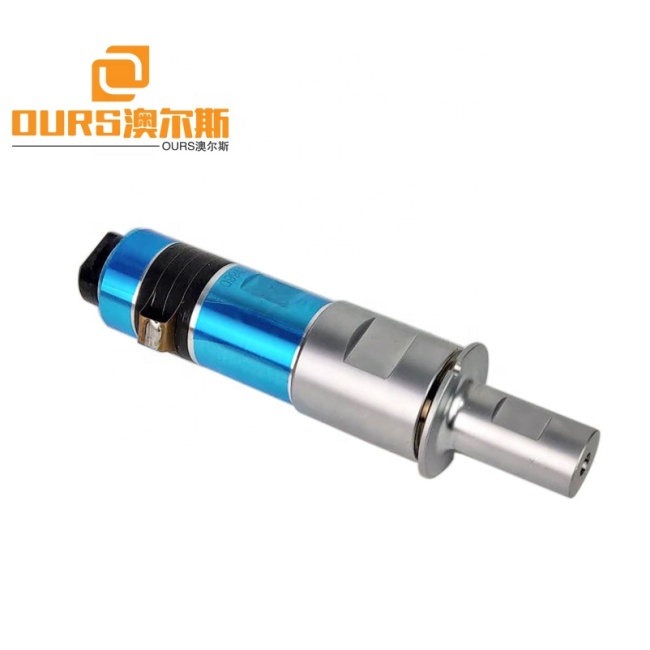

High Efficiency 20KHZ 2000W Ultrasonic Welding Oscillator Transducer For Non-woven Fabric Welding

1-49 Piece

$350.00

≥ 50 Piece

$320.00

- Item No.202103147c860MOQ1 Piece

- Product size45 x 42 x 26 cmProduct weight8 kg

Choice

Quantity:

If you have your own design, please contact us, there will have a professional customer service to communicate with you.

Don't have your files right now?No worries, Check out our art tips for more information.

If over 500pcs, mass production will start until pre-production sample has been approved.

Est. 7 days production

High Efficiency 20KHZ 2000W Ultrasonic Welding Oscillator Transducer For Non-woven Fabric Welding

Ultrasonic waves are transformed into mechanical vibrations through transducers. The characteristics of transducers depend on material selection and manufacturing process. The performance and service life of transducers of the same size and shape are very different. The commonly used high-power ultrasonic transducer is used in ultrasonic plastic welding machine, ultrasonic metal welding machine, various handheld ultrasonic tools, continuous working ultrasonic emulsifier, atomizer, ultrasonic engraving machine and so on. Commonly used products such as 15KHz 20KHz 28KHz 35KHz 40KHz 55KHz 70KHz can also design and produce non-standard transducers according to the special requirements of customers to meet all kinds of needs.

Ultrasonic welding is an industrial technique through which a very high-frequency ultrasonic acoustical vibrations are applied to the work pieces locally and which are being confined together under the influence of high pressure in order to develop a solid-state weld, mostly used for plastics. In other words, it is the joining or altering of thermoplastics via heat which is generated from high-frequency mechanical motion. Electric energy of high frequency is converted into mechanical motion of the same high-frequency to attain welding process. This mechanical motion along with the force which is applied generates frictional heat at the plastic components’ joining surfaces. This will enable the plastic material to melt and form a molecular bond amongst the parts.

Ultrasonic Welding Process

The ultrasonic welder machine will comprise of components such as – Transducer, Sonotrode and Anvil. The complete welding mechanism will include the following steps:

A stationary clamping force is put exactly perpendicular to the interface in between the work pieces.

Then the contacting sonotrode of the welder oscillates parallel to the interface.

This coalesced effect of stationary and oscillating force generates deformation which furthers welding.

Ultrasonic welding is a technology in which an ultrasonic generator drives an ultrasonic transducer, vibrates tens of thousands of times per second to generate heat, and instantly melts and joins the plastic surface. Therefore, the quality of the ultrasonic transducer, It is an important factor that determines the function of the welding machine. The ultrasonic vibration head produced by Jingda Company has the characteristics of large output power, high conversion efficiency, low heat generation, and stable quality. It is the best component of the plastic welding machine.

Ultrasonic transducers are widely used. According to the application industries, they are divided into industry, agriculture, transportation, life, medical treatment and military. According to the realized functions, it is divided into ultrasonic processing, ultrasonic cleaning, ultrasonic detection, detection, monitoring, telemetry, remote control, etc.; according to the working environment, it is divided into liquid, gas, biological body, etc.; according to the nature, it is divided into power ultrasonic, detection ultrasonic, ultrasonic imaging, etc. .

The piezoelectric ceramic transformer uses the piezoelectric effect of the polarized piezoelectric body to realize the voltage output. The input part is driven by a sinusoidal voltage signal and vibrates through the inverse piezoelectric effect. The vibration wave is mechanically coupled to the output part through the input and output parts. The output part generates electric charge through the positive piezoelectric effect to realize the electric energy of the piezoelectric body. -Mechanical energy-two transformations of electrical energy to obtain the output voltage at the resonant frequency of the piezoelectric transformer. Compared with the electromagnetic transformer, this has the advantages of small size, light weight, high power density, high efficiency, breakdown resistance, high temperature resistance, no fear of burning, no electromagnetic interference and electromagnetic noise, and simple structure, easy production, and easy mass production. In some areas, it has become an ideal substitute for electromagnetic transformers and other advantages. This type of transformer is used in switching converters, notebook computers, neon lamp drivers, etc.

| (external sizes) | (electeomachanical characteristic) | ||||||||

| Specification | Connect Screw | Ceramic diameter(mm) | Quantity of Ceramics(pcs) | Resonance Frequency(kHz) | Resistance | Yellow Ceramic | Black Ceramic | Input Power | Max Displacement(um) |

| ARS-6015-4C-Si | M16*1.0 | 60 | 4 | 15 | 15 | 9500-10000 | 12000-12500 | 2200 | 11 |

| ARS-6015-4C-Tr | M16*1.0 | 60 | 8 | 15 | 15 | 19500-20000 | 4200 | 11 | |

| ARS-6015-4C-Qu | M16*1.0 | 38 | 12 | 15 | 15 | 22500-23000 | 27500-28000 | 3200 | 11 |

| ARS-6015-6C-Si | M16*1.0 | 60 | 6 | 15 | 15 | 18500-20500 | 2600 | 11 | |

| ARS-5020-4C-Si | Imperial 3/8 | 50 | 4 | 20 | 15 | 11500-12000 | 13500-14000 | 1500 | 8 |

| ARS-5020-6C-Si | Imperial 3/8 | 50 | 6 | 20 | 15 | 19000-21000 | 2000 | 8 | |

| ARS-5020-4C-Tr | M16*1.0 | 50 | 8 | 20 | 15 | 23000-24000 | 3200 | 8 | |

| ARS-5020-4C-Tr | M16*1.0 | 38 | 8 | 20 | 15 | 17500-18000 | 3200 | 8 | |

| ARS-3828-4C-Si | Imperial 3/8 | 38 | 4 | 28 | 15 | 8000-8500 | 1000 | 5 | |

| ARS-3035-4C-Si | M8.1.25 | 30 | 4 | 35 | 15 | 5200-5600 | 800 | 4 | |

| ARS-3040-4C-Si | M10*1.5 | 30 | 4 | 40 | 15 | 5200-5600 | 800 | 2 | |

High Efficiency 20KHZ 2000W Ultrasonic Welding Oscillator Transducer For Non-woven Fabric Welding

Send your message to us

No need register, just fill in contact info below, we will reply you within 24 hours!

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian