Ultrasonic Transducer Piezoelectric Sensor 28KHZ or 40KHZ For Cleaning Car Engine

Tuning matching plays an important role in the system of ultrasonic generator. First, when the ultrasonic transducer is in the resonant state, it usually presents a capacitive state. Through matching network, the capacitive impedance is compensated, so that the load of the ultrasonic generator is as close as possible to the pure impedance state, so as to reduce the reactive power component. Impedance matching: According to AC theory, when the power supply impedance and load impedance are equal, the load can obtain the maximum power. Because the ultrasonic transducer has the characteristic of impedance model, the impedance characteristic of the power supply load of the whole ultrasonic generator is changed by matching network, and the appropriate parameters are selected to make the load impedance close to the power supply impedance, so that the ultrasonic wave can obtain larger electric power. At present, domestic and foreign scholars have carried out in-depth research on the matching network of ultrasonic transducers. Based on the equivalent circuit, a simple L-C matching network is used to obtain the maximum conversion power and improve the efficiency of the ultrasonic transducer.

From the perspective of excitation mode of ultrasonic transducer, it can be divided into two excitation modes: self-excitation mode and self-excitation mode. Because the vibration modes of the two generators are different, for its excitation generator, it is necessary to know the specific parameters of the ultrasonic transducer, including the working frequency. The inductance value to be connected can be roughly calculated by calculating formula, while the self-excitation generator usually determines the working frequency by connecting the inductance value. From the point of view of impedance matching, how to do this is analyzed. A matching network is composed of a pulse transformer and R, L and C between the generator and the ultrasonic transducer. Based on the analysis of the basic principle of ultrasonic transducer and the electrical equivalent circuit, the capacitance matching, inductance matching, LC matching and T-type matching are studied, and the basic calculation methods of these matching modes and parameters are given, and each matching is analyzed. The advantages and disadvantages of these two matching methods have good reference value for static matching. By analyzing the characteristics of series inductance matching and parallel inductance matching on the frequency of ultrasonic transducer, combining the advantages of these two matching methods, an L-type matching network is proposed, and the effects of these matching methods on working frequency and the changes of electromechanical coupling coefficient are compared, which provides one for static matching network. Ways of planting.

7. High performance: mechanical Q value, high vibration efficiency, high amplitude.

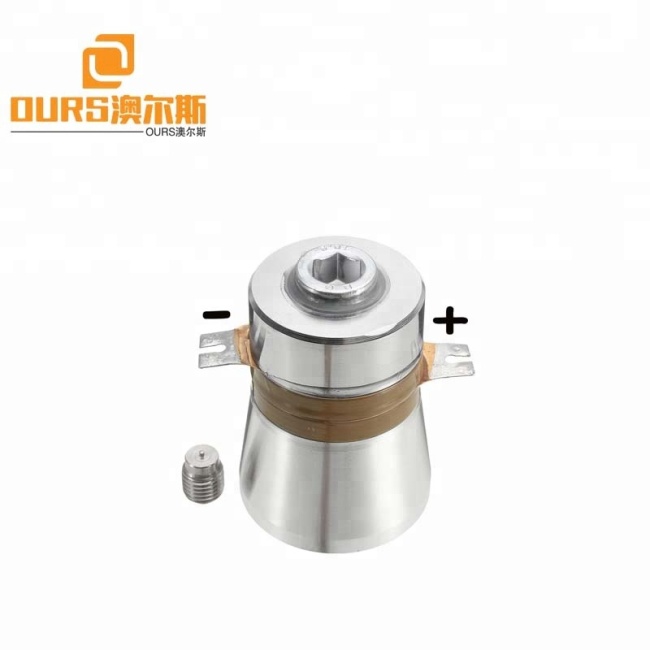

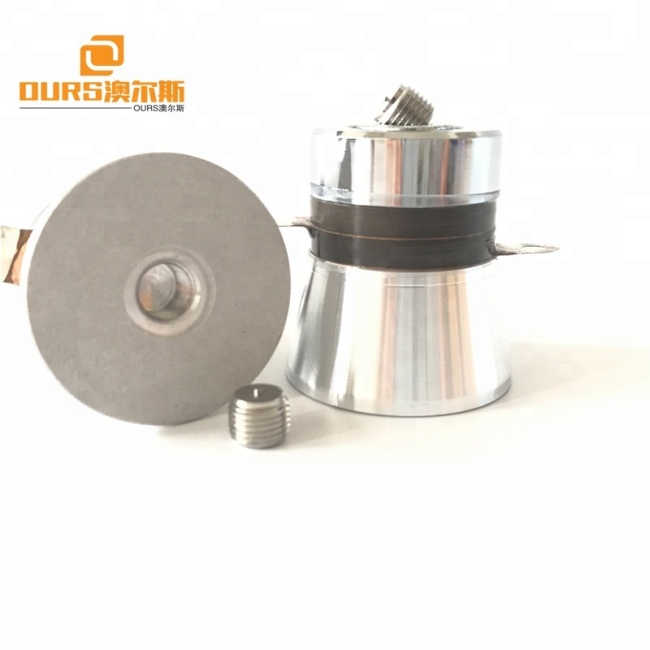

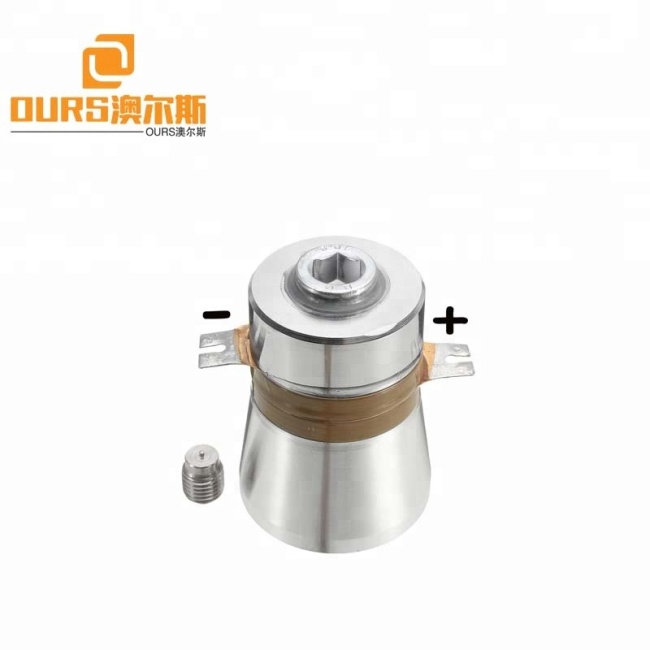

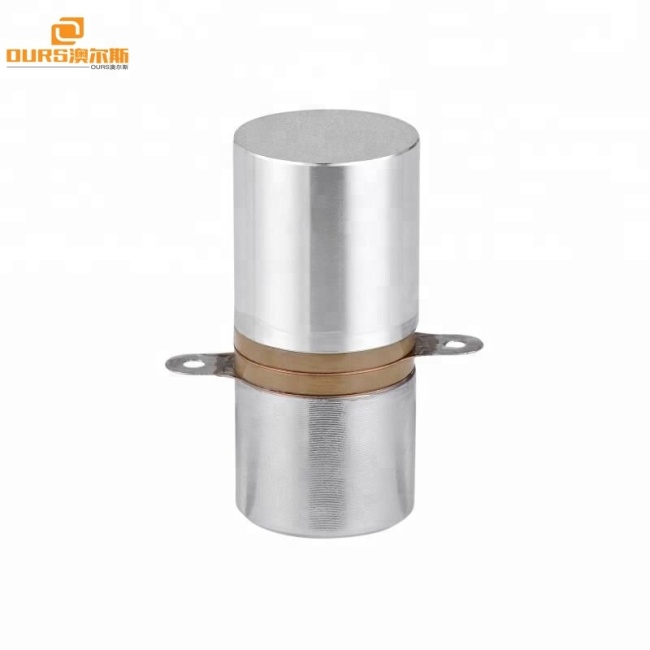

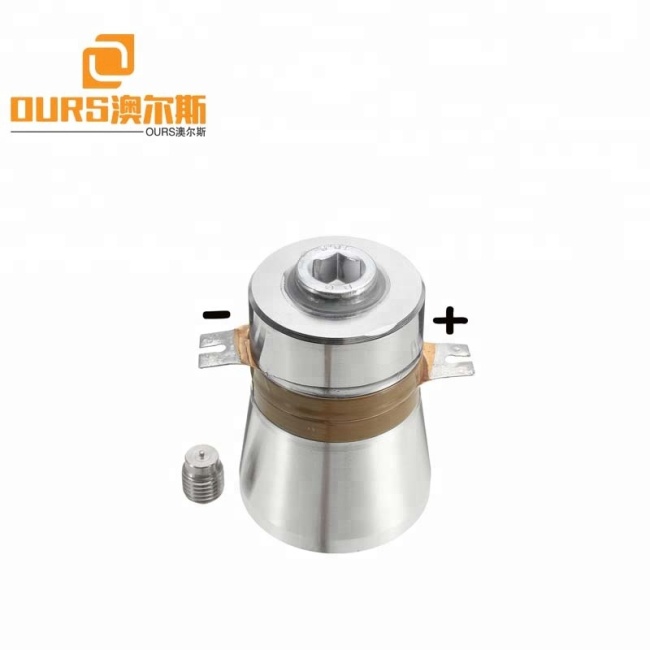

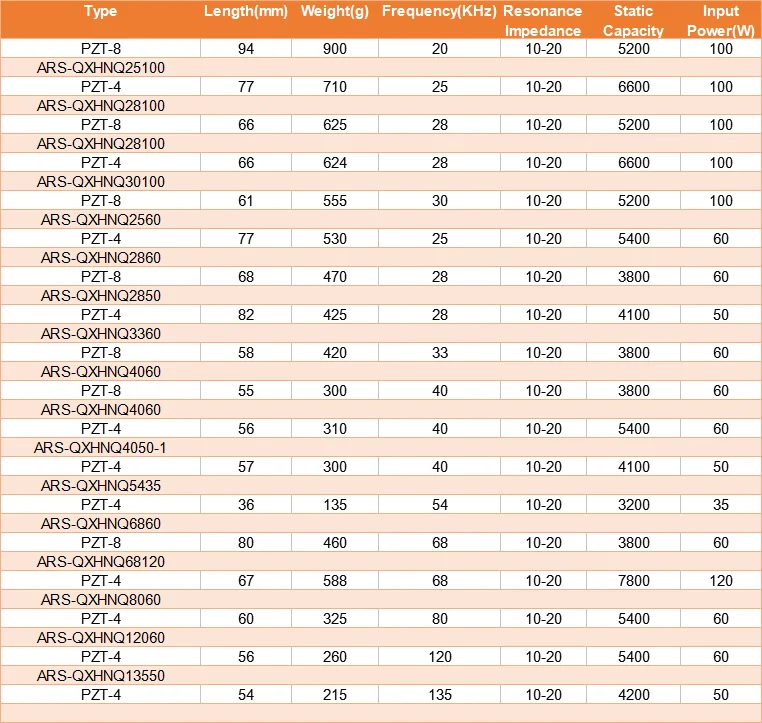

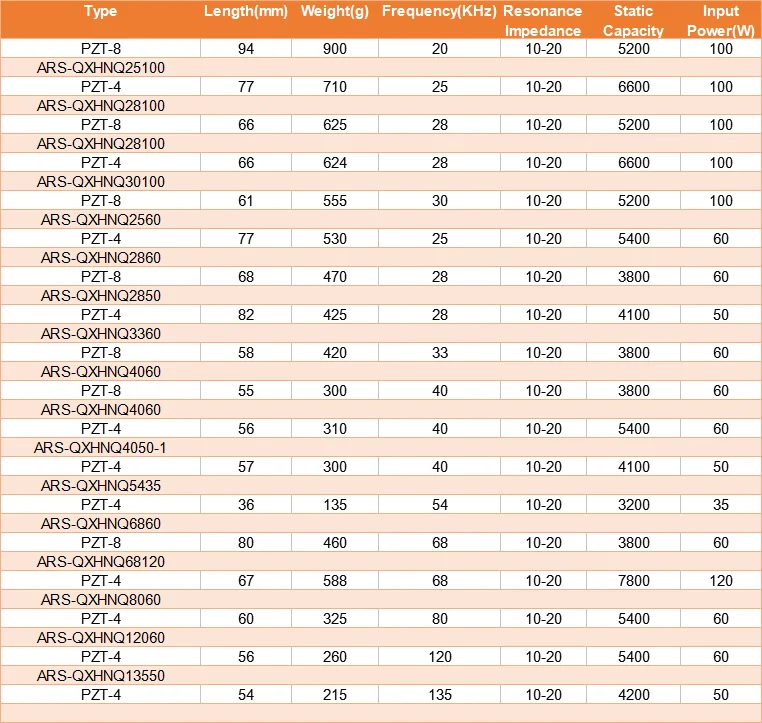

Ultrasonic vibrator, also called ultrasonic vibrating head, ultrasonic vibrating head, is a kind of ultrasonic transducer and the core component of ultrasonic cleaning machine. Industry standard name: Ultrasonic transducer, belongs to piezoelectric ceramic material, one of the main accessories of ultrasonic cleaning machine. In terms of power, a single ultrasonic vibration head is 60W and 100W. The frequencies are: 20KHZ, 25KHZ, 28KHZ, 40KHZ, 68KHZ, 80KHZ, 100KHZ, or higher; the difference in shape is: straight cylindrical shape, horn shape, etc.

With the development of ultrasonic technology and the deepening of the application of power ultrasonic equipment, the performance of power ultrasonic equipment depends largely on the quality of the power piezoelectric ceramic vibrator.

The transducer vibrator converts the high-frequency excitation current into ultrasonic vibration, which is the driving part of the sandwich piezoelectric ceramic transducer. The performance of the entire transducer system depends largely on the quality of the transducer oscillator. When designing and manufacturing a low-frequency sandwich piezoelectric ceramic transducer, the transducer vibrator must be designed first. The frequency of the vibrator ultimately determines the frequency of the sandwich Yaodan ceramic transducer.

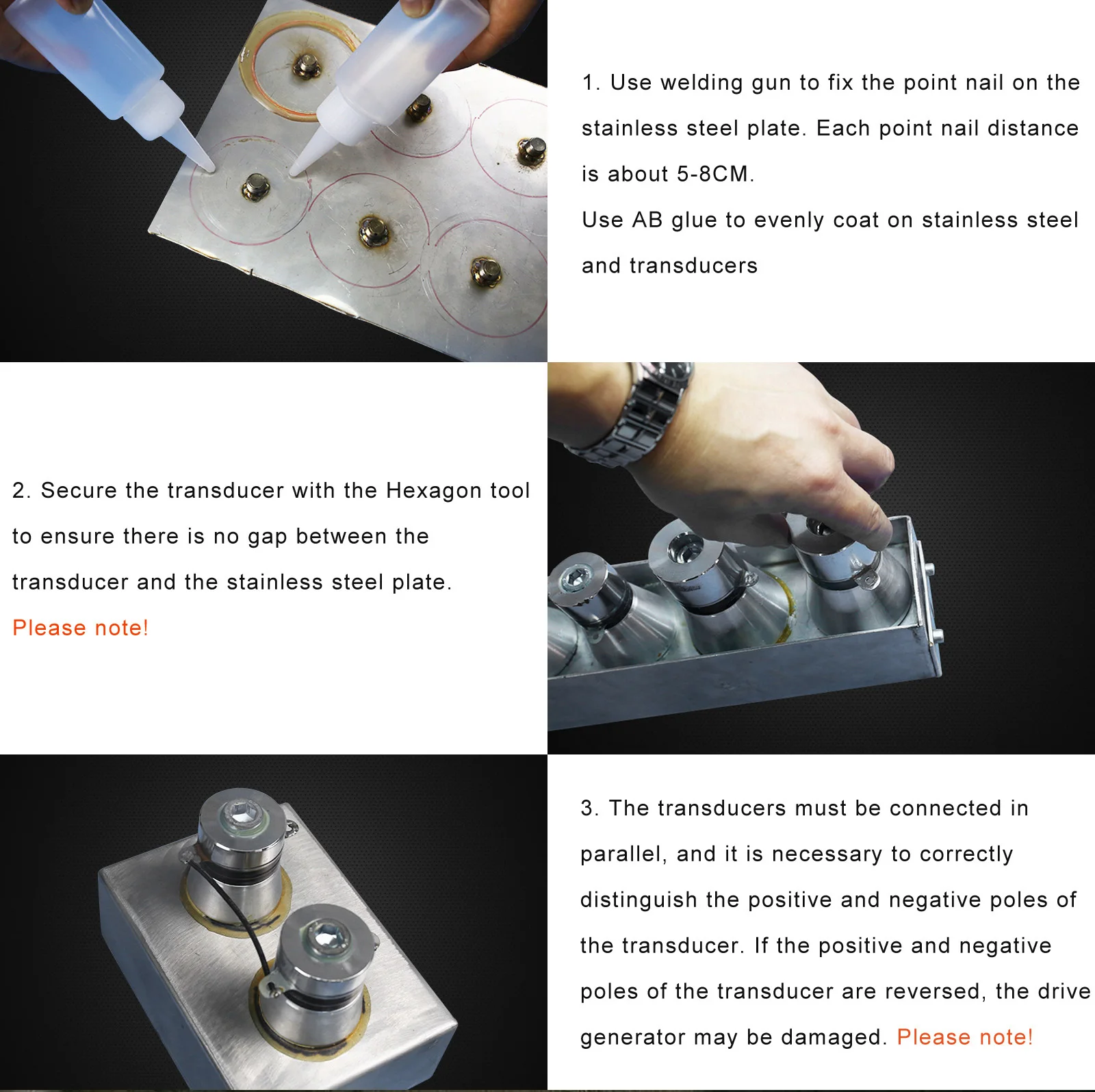

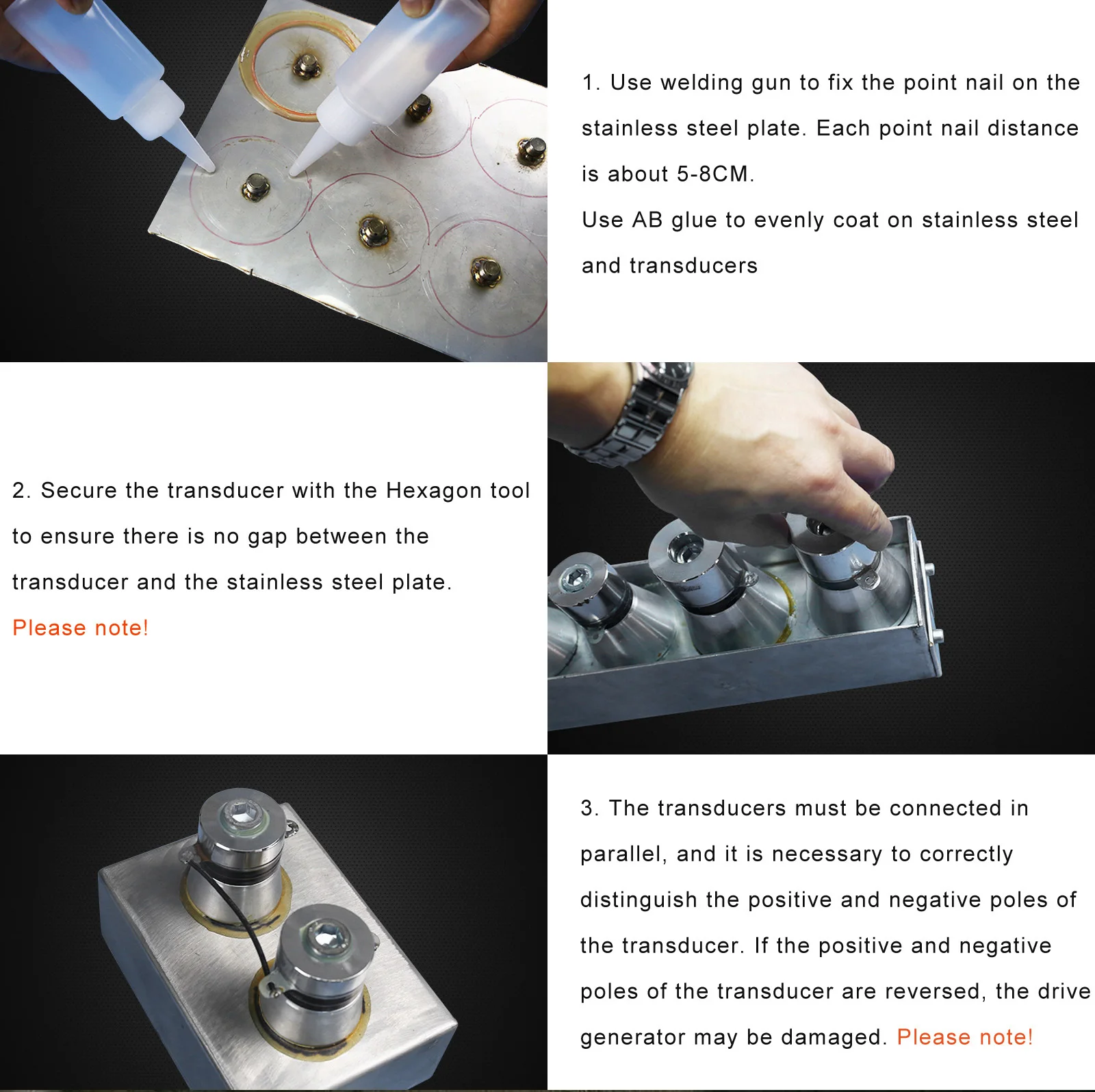

To install an ultrasonic vibrator, you must first understand the structure of the ultrasonic vibrator and the working principle of the ultrasonic vibrator. In fact, the ultrasonic vibrator is also called the ultrasonic vibrator. In the industry, the whole of the transducer and the horn is called the vibrator.

Ultrasonic vibrator is a device that realizes the mutual conversion between electrical energy and mechanical energy (acoustic vibration) by the piezoelectric effect of piezoelectric ceramics, and amplifies the device through the front and rear radiation cover blocks that match the acoustic impedance. The ultrasonic vibrator is composed of an ultrasonic transducer and an ultrasonic horn. Ultrasonic transducer is a device that can convert high-frequency electrical energy into mechanical energy. Ultrasonic horn is a passive device that does not produce vibration itself, but only changes the vibration input from the ultrasonic transducer before transmitting it out. The impedance transformation.

Ultrasonic Transducer Piezoelectric Sensor 28KHZ or 40KHZ For Cleaning Car Engine

English

English German

German French

French Russian

Russian Spanish

Spanish Japanese

Japanese Korean

Korean Portuguese

Portuguese Ukrainian

Ukrainian Arabic

Arabic Italian

Italian